Concrete Overlays

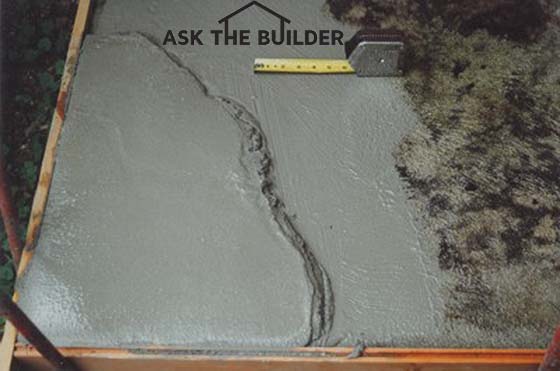

Here's a concrete overlay on a small concrete slab. You can see the form boards that allow you to get the top in the same plane. There's a nice coat of cement paint that bonds the new overlay to the old concrete. (C) Copyright 2018 Tim Carter

"In addition, a liquid bonding agent or traditional cement paint can be brushed onto the damp slab immediately prior to pouring the overlay."

Cement Paint & Concrete Overlay Installation Checklist

- Remove all crumbling concrete and dust

- Overlay stones no larger than 1/3 thickness of the overlay

- Use secret cement paint to bond overlay to the old concrete

- Dampen old concrete slightly before applying the cement paint

- Cover the overlay with plastic to cure it for 48 hours

DEAR TIM: My concrete sidewalks and driveway look horrible. For some reason, the top 1/8 to 1/4 inch of the finish surface has peeled up in patches.

The contractor I used blames road salt for the damage. Is it possible to patch the concrete with some mixture that will last for a long period of time? If so, how is the task completed? Is this a task that the average person can tackle? Betty G., Ft. Wayne, IN

Related Links

Concrete Resurfacing Tips & Tricks - DO NOT SHARE!

More Concrete Restoration Professional Tips

CLICK this image and listen to the first call on the podcast. I talk to Vic about how he can do a concrete overlay to SAVE thousands of $$$. Copyright 2018 Tim Carter

DEAR BETTY: What a shame! Exterior concrete that is ordered, mixed, installed, finished and cured properly can withstand many, many years of exposure to road salt and freeze and thaw cycles that occur during cold winter months.

Free & Fast Bids

CLICK HERE to get FREE & FAST BIDS from local concrete resurfacing contractors.

Why Does Concrete Spall?

The most common reason for concrete spall is water was sprinkled on the concrete during the finishing process. Extra water could have been added to the entire mix when the truck arrived at the job site.

There are many things that could have gone wrong that most likely caused the concrete wear surface to fail, but the good news is that there is a repair method that will yield long-lasting and beautiful results.

Can a Thin Overlay Be Applied to Concrete?

Residential contractors and large-scale commercial concrete contractors can install a thin overlay on concrete slabs that have damaged surfaces.

The overlay material can be a simple mixture of sand and cement or it can actually be a real concrete mixture that includes small pieces of stone or even large stones depending upon the thickness of the overlay. Cement or concrete overlay thicknesses can range from 1/4 inch thick up to a full 2 inches or more.

How Do You Install a Concrete Overlay?

The secret to success is a combination of ingredients. You must determine that the existing slab is sound. Be sure that the exposed parts of the slab are not crumbling.

Tap the damaged areas moderately with a hammer. If the slab sounds solid and it is difficult to do further damage to the slab with moderate hammer blows, the existing concrete is probably a superb candidate for an overlay.

What is the Best Weather to Install a Concrete Overlay?

Weather conditions also impact the success of the overlay. Cool days with temperatures in the 50 F range are ideal.

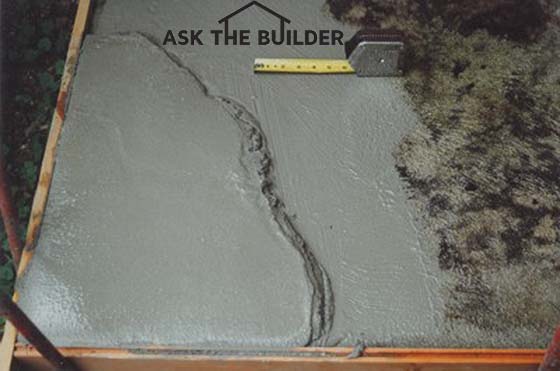

It's even better if there is little or no wind and the skies are overcast. Heat, sunlight, and wind cause the overlay mixture to dry too rapidly. Rapid drying makes it harder to work and finish the overlay. These conditions can also cause undesirable plastic shrinkage cracks in the surface of the brand new overlay.

How Do You Achieve the Best Bond?

The overlay mixture will bond permanently to the existing concrete slab, if you make sure the existing slab is clean, dust-free and slightly damp before you apply the overlay.

In addition, a liquid bonding agent or traditional cement paint can be brushed onto the damp slab immediately prior to pouring the overlay. Cement paint is simply a mixture of Portland cement powder and water. Add enough water to the cement and mix it until it is the consistency of regular latex wall paint.

How Much Portland Cement Should be in the Overlay Mix?

It is important that a sufficient amount of cement is added to the overlay mixture so that it will resist freeze-thaw cycles that will occur in the winter months.

Since your overlay material will be mixed most likely in a wheelbarrow or a rented mixer, be sure that you include 1 measure of Portland cement for every 2.5 measures of sand for thin overlays. If you are going to include stones or larger aggregate, then the mixture should be:

- 3 measures of gravel

- 2 measures of sand

- 2 measures of Portland cement

How Do You Apply the Overlay?

The overlay mixture is installed over the existing slab just like the original concrete pour. Form boards are placed alongside the existing slab.

The top of the boards are set so that they create a plane that represents the desired final thickness. Once the overlay material is dumped in between the form boards, a long straightedge board can be used to remove excess overlay mixture. The straightedge board extends over the form boards and is wiggled back and forth to smooth out the overlay.

How Soon Do You Apply the Final Finish?

Depending upon the weather conditions and the moisture content of the overlay mixture, the final finishing process can begin within 10 minutes, or in some cases, up to an hour after the mixture is poured. Be sure to apply a liquid curing compound on the overlay as soon as the final finish is complete.

Is An Overlay a DIY Project?

Overlays can be done by homeowners. The entire project does not have to be completed in one day. You can work on one or two sections each day.

To make sure the final color of the overlay matches, be sure that all of the necessary materials are bought at the same time. Mixing brands of Portland cement and using different sand can cause color differentiation when the materials cure.

Column 429

13 Responses to Concrete Overlays