Cracked Treated Wood

Can you believe this piece of treated lumber is new? It looks like a 30-year-old fishing pier. Copyright 2017 Tim Carter

Cracked Treated Wood TIPS

- Treatment chemicals evaporate causing cracks

- Seal with synthetic-resin sealers - See my test results below

- WATCH wood epoxy video series below

- Apply sealer within days of installing treated lumber

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: Over the summer, I ripped up the old boards on my deck and replaced them with new pressure treated boards.

Now that they've had time to dry out, I'm about to stain the deck but I've discovered that a handful of boards are already splintering and cracking. This is really disappointing especially since I spent a little extra on the premium boards.

What's your advice on what I should do to remedy this? Would power washing help our just produce the same result?

Or should I replace the problem boards altogether? Should the warranty on pressure treated boards cover this? Adam W., Dallastown, PA

DEAR ADAM: Oh my, what a shame you had this happen.

Answers Abound At AsktheBuilder.com

It's so unfortunate because for years I've had the remedy at my AsktheBuilder.com website in past columns about wood deck maintenance and care.

If you would have visited my website and spent just thirty minutes researching how to care for new lumber, you'd not have this problem.

You Goofed Up

I hate to break this to you, but the entire issue was caused by you. It's very unfortunate the lumber suppliers and the store you purchased it from didn't tell you the best way to protect your investment as you left the store.

I assume they didn't.

CLICK HERE to get FREE & FAST BIDS from local companies that will seal your deck lumber.

Treated Lumber Can Be Very Wet

Here's what's going on. Treated lumber is injected with chemicals that are mixed with water.

Years ago, some of the treated lumber I worked with was so saturated with the water-based chemical brew that when you'd drive a nail into it, this liquid concoction would squirt out alongside the nail shaft as you drove the nail.

Sun & Wind Tear It Apart

As soon as you expose most treated lumber to the sun and wind by nailing it to deck joists, the liquid in the wood begins to exit to the air.

When the sun extracts this moisture out of the lumber, it creates significant tension stress within the wood fibers. Tension is the force that happens when you try to stretch, bend or pull something.

The lumber shrinks as the water leaves the wood leaving the chemicals behind that are intended to prevent the wood from rotting.

Cracks Replace The Water

This shrinkage usually causes tiny checking cracks to form. The cracks that are now filled with water take up the space previously occupied by the water that was in the wood.

These small check cracks are often about the width of a piece of paper and perhaps only an eighth of an inch long. In extreme case you can experience de-lamination along the boundaries of the summer and spring wood.

Summer wood is the dark ring you see in a log and the spring wood is the lighter-colored band.

Giant Splinters

When this de-lamination happens on flat-grained pieces of lumber, you end up with giant protruding splinters like I see in the photo you sent. There's no way to repair these.

Cracks Enlarge

Once you have cracks in the wood, you've got problems unless you stop the water from soaking into the wood. When the water soaks deeper into the wood by entering the cracks, as the sun and wind come back after the rain storm, the wood starts to shrink.

Each time this happens the tension forces usually cause the cracks to get bigger and bigger.

Pressure or Power Washing is BAD

Power washing lumber is the worst thing you can do. The high-pressure concentrated stream of water blasts away the less-dense spring wood.

What's more, it drives water deep into the cracks you already have. This is the last thing you want to happen.

Pressure Washing Video

Watch this video to see more damage caused by pressure washers.

Ground Water Vapor

To make matters worse, if your decking is close to the ground, say about 2 feet or less, water vapor coming up from the soil under the deck can damage the decking.

This water vapor causes the face of the decking on the underside of the deck to expand because water is entering the wood fibers.

On the other side, the sun and any wind is doing the opposite causing moisture to leave the wood. As we discussed, this causes the wood to shrink or get smaller.

CLICK HERE to get FREE & FAST BIDS from local companies that will seal your deck lumber.

Cupped Decking Boards

When this happens, the decking will almost always cup. This means the decking gets higher on the edges and lower in the center much like a valley between two mountains.

Seal Treated Wood Immediately

You could have avoided this costly nightmare by just staining and sealing the wood as soon as it was installed. You want the wood to be dry enough so the sealers soak in, but not so dry as the tiny checking cracks are starting to happen.

Deck Sealer Test Results

A few years ago I did an independent test on name-brand deck sealers. I took extensive before and after photos to show how well each sealer performed on treated lumber and on cedar decking.

These are four pieces of wood that were part of my extended outdoor wood sealer test. The two pieces on the left are cedar and the two smaller pieces are treated lumber. The dark gray, nearly black, piece was only out in the weather for four months. The piece to the right is what it looked like BEFORE it was put out in the sun and water!!! CLICK THIS IMAGE to get access to the full test results. Copyright 2017 Tim Carter

High-quality sealers stop water from entering treated lumber. You can often see water beading on decking that's been treated with a great sealer.

CLICK HERE to get access to my independent test of deck sealers. You'll be able to discover who won my test.

Edges & Ends

While it requires much more work and stain / sealer, it's not a bad idea to seal and stain all sides and edges of the decking before it's installed. This means you need to have a place to set out each piece to dry after you've applied the sealer.

It's best to create a drying rack in a carport or inside a garage. The last place you want to place the freshly sealed boards is out in the direct sun where they can twist and warp as they dry.

Salvage & Sand

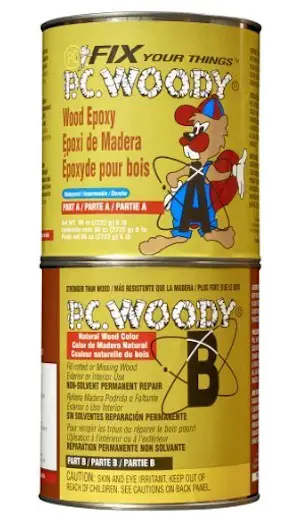

This is a great wood epoxy that will fill larger cracks in wood decking and outdoor wood. If the wood is starting to rot, get the kit that has the PC Petrifier component. CLICK THE IMAGE NOW TO HAVE THIS PRODUCT DELIVERED TO YOUR HOME.

You may be able to salvage some of the boards that are not too bad. I'd use a belt sander with medium sandpaper to see if you can make them look presentable.

The great sealers and stains will stop water from entering tiny checking cracks so if that's all you see after sanding, I'd keep those boards.

You can use a great waterproof wood epoxy to fill large cracks. It's stainable and while it won't look exactly like the natural wood, you'll stop water from doing more damage once you seal the wood and coat the epoxy.

Any others that have large splinters or delamination will have to be replaced. Don't expect the lumber company to give you free replacements as they know you caused the issue.

You may be able to get a significant discount on your replacement boards if you talk to the lumberyard manager.

Mention that you feel they should have given you a small pamphlet about how to care for the wood. I wish you the best of luck and be sure to follow any and all directions on the labels of the sealer / stain you purchase.

Wood Epoxy Install Videos

Watch this video series to see how to use the magic wood epoxy. It's very easy and you can save lots of money and time using this product in many instances.

CLICK HERE to get FREE & FAST BIDS from local companies that will seal your deck lumber.

Column 1116

I have been replacing my fence the last couple of years and I did the exact same thing you suggest. I stained each picket and 2 by 4 before I put it together. I used cedar pickets and pressure treated 2 by 4's . I put on two oats of solid color stain before I assembled the fence. I see neighbors in the neighborhood getting new fences built and they don't bother staining them. most are pressure treated pickets. I just shake my head knowing what they are going to look like in a year.

Tim,

I'm a little confused by your comment to seal the lumber right away. As you noted, when driving a nail in a new piece of treated lumber, you may find liquid seeping out around the nail. This same saturation prevents the wood from soaking up any additional stain you would try to apply. I have received the "directions" on finishing pretreated lumber. It states that you need to let the boards dry out before applying the new stain. They say that you'll know when the right time is by sprinkling a little water on the boards. If it beads up, it's still too fresh to apply the finish. However, there is a fine line regarding too soon and too late. If you wait too long, the splitting and cracking may begin to occur.

I hope I'm not being too critical. This is just what I've experienced over the years. Thanks for all you do. Your articles are very helpful.

The newer 2015 PT brown wood was absolute garbage. I am talking the first batches they ran were just horrible as I don't think they had the recipe figured out correctly.

I built a deck last summer (2015) which was the first time I saw brown PT deck wood. They had no green PT left at all so was forced into buying the brown PT which looked way nicer anyways.. I was told not to stain or seal the wood till the following summer so we waited.. Within weeks of installing, the deck boards cracked very badly, the 4x4 posts were absolutely horrible and twisted worst than I have ever seen, on top of the cracking.. All that was noticed last summer while I built the deck..

Fast forward to this past summer of 2016.. The deck boards was cracked and shrunk really bad.. I put Thompson clear sealer on it to help prevent any further expansion due to water and the wood shrank even more to the point the deck creeks and cracks when you walk on it.

About 6 weeks ago I had to replace about 10 boards so off I went to pick up some deck boards.. What I noticed with this years batch of brown PT wood is it looks greener.. To me this says they changed the recipe because the wood from last year was completely brown with no green at all... This new wood has brown/green look to it, and the wood seems in much better shape.. ITs been on for about 6 weeks now and has zero cracks in it. By 6 weeks in last year, the pure brown PT was cracked and splitting all over the place..

I really felt ripped off by such a bad batch of wood.. Even the 2x8 and 2x12 joists from 2015 pure brown PT was warped and just flat out bad wood..

So I went to complain to the store I bought the original brown PT from about how badly cracked it was just after one year.. So the guy asks me If I sealed it after I put it up, I said ya we wait 2 months then sealed it.. So he says, oh thats why it cracked then.. I said what do you mean? He said I should have waited a full year and did the sealing this summer (which I did but I knew no matter what answer I gave he was gonna lie and says whatever I did caused the wood to spit) .. So I said, Actually I did wait a full year to seal it, and the wood was so dry and split it had to be done to salvage whats left of the integrity.. and he started stumbling over his words and stuff.. i knew he was gonna blame and try to get out of some sort of reparations.. I just told him, don't worry about it, I will never be buying wood here or anything from here again.. IT was from a local hardware store called Soo Mill.. It might be a local brand none of you heard about but its akin to timbr mart or lowes..

I now buy all my wood from home depot, it seems to be a bit better shape.. I am just pissed because I helped my dad build his deck over 8 years ago with green PT and it looks 100x better with no cracks.. I truly believe I got fked by the new first run of brown PT they put out in 2015..

live on fix income, save for deck out of my trailor...so I wouldn't fall on the steps, only 1 month old and there are crackes every where. What do I do?? Can I seal it so it will last a few years.. I am 75 and sure can't pay for another one.. Thank You.

Patricia,

After reading your comment, I took the time to REVISE the above column to answer your question. Go back up, re-read it and watch all the videos, especially the last four. See the link up there about the amazing wood epoxy? CLICK that link and get some right away. Her's the link now if you can't wait:

http://amzn.to/2mNfbk7

Was interested in seeing your wood sealants test and then got stunned when I realised you are actually selling it. Is that really necessary with all the ads you already have on your site? Who sell article access/test result on the web in 2017?

I sell them. It was very time consuming and expensive to gather all the materials, do the test, take the photos, put together the PDF file, etc. If you want to do all that for free for the benefit of mankind, that's awesome. But I don't see you doing it.

Consumer Reports doesn't give their test data away for free. You don't work at your job for free.

Why would you expect me to work for free?

If it's such a good idea to do tests like this and give away the results, tell me what are the top three product tests you'll be doing in the next three months. What's more, I'll offer up my entire platform for you FOR FREE to give them away to mankind.

Let me know what tests you'll be running.

Would painting it right away with a latex paint prevent the same thing from happening?

We watch 4 videos and there's no money shot? It's like leaving the theater 10 minutes before the ending of the movie!

The videos were shot in Los Angeles. I live in NH. The WX didn't really cooperate enough for the epoxy to get hard enough to sand prime and paint before I had to go back home.

If you were paying for the videos like you do at the movie theater, I can see why you'd be upset. But you get to watch all my videos for free. I'm sure you can imagine how the window sill would look perfect once sanded and painted.

Just received a large load of pt .40 deck boards on 9/20 and installed a few rows on 9/22. Only installed the perfect boards. No checks. By 9/23, all boards had several checks. Did not apply any sealer/stain since i figured it was cloudy and rained off and on during the brief install. Live in WA state. First, was it a mistake not to let the boards dry some BEFORE installing them? Second, do i need to seal/stain the boards immediately as I install them? One day..and they check. Just ridiculous. Lastly, does checking in wood decking natually occur and is NOT preventable regardless of what product or sealer is used? Help in WA to find some resolution. Thank you

What is the recommended process for boards before installing them (other than your recommended staining)? I've read about leaving boards out for a few days but there are differing opinions it seems.

Hi Tim,

Thanks for the great tips. There is one major issue with your sealing recommendation. Unless you use hard-to-find Kiln Dried After Treatment (KDAT) treated lumber, you have to allow it to dry in a low humidity area (e.g., in a garage with a dehumidifier) before you can seal it. Several sealer manufacturers I've spoken to require no more than 18% moisture content before you can use their product. The treated lumber you find at lumber yards or home improvement stores is very wet and need significant drying before a sealer can be applied. The challenge is that long cracks appear in the lumber even during this controlled drying. Short of finding a KDAT treated lumber supplier (I've called a dozen lumber yards in my area and no one stocks it or is willing to source it), it seems impossible to avoid these checks/cracks. Any suggestions how to keep the wood from developing cracks during the controlled drying process?