Water Heater Anode Rods

"Tank corrosion is the #1 cause of water heater failure. Keeping a water heater anode rod in good shape prevents failure."

Water Heater Anode Rod Checklist

- the anode rod is hidden in the tank

- it sacrifices itself to save the tank

- it must be replaced every seven years

- water heater can last forever if you replace the rod regularly

Water Heater Anode Rod - Replace Every Seven Years

The water heater anode rod you can't see is why you have delightful hot water in your home. There's nothing quite like that warm shower in the morning or after a hard day's work.

Do you take hot water for granted? We use it throughout the day for bathing, washing dishes, clothes, etc. It has become a necessary element of our lives.

Related Links

Tough Love Truth About Tankless Water Heaters - DO NOT SHARE! Angry Companies

Venting Water Heaters - Do it the SAFE WAY

Free & Fast Bids

Where are Anode Rods?

A water heater anode rod is suspended inside the water heater tank. The anode rod protects the water heater from corrosion.

This is a replacement anode rod made from both aluminum and zinc. It prevents the rotten egg smell you get with magnesium anode rods. It's in sections so you can get it into the tank with a low ceiling above the water heater. CLICK THE PHOTO to have a new anode rod at your home in two days.

Water heaters are very simple mechanical items. They have virtually no moving parts. Electric water heaters have very small switches that turn the current on and off automatically to each heating element.

Gas water heaters have small parts within the gas valve that control gas flow when it is necessary for the burner to cycle on or off. Rarely do these moving parts fail.

Why Do Water Heaters Leak?

Tank corrosion is the #1 cause of water heater leakage and failure. Keeping an anode rod in good shape prevents failure.

High-pressure failures are also becoming a problem as well. Both of these problems can be somewhat controlled. You simply need to consider several alternatives before you install your next hot water heater.

What Causes Corrosion in a Water Heater?

Corrosion within hot water heaters can be caused by water acidity, electrical conductivity, dissolved oxygen, and temperature. Water can react chemically with metal parts inside of the water heater.

Acidic water can actually eat away at the metal. This corrosion process is accelerated with temperature. So as we heat the water for our usage, we actually can hurt the tank!

When Did Water Heaters Get Glass Linings?

Water heater manufacturers began lining the steel tanks with a thin coating of glass in the 1950s. This coating isolated the steel tank from the corrosive water.

Any part of the water heater tank not coated with glass is a place where corrosion can begin.

The inlet and outlet holes of the tank are not glass coated. These areas are subject to corrosion.

Are Gas Heaters Likely to Corrode Faster?

Gas water heaters are likely to corrode faster. Every time the burner turns on it heats the metal at the bottom of the tank. This heat causes the metal to expand.

When the burner shuts off, the metal contracts. This constant expansion and contraction weakens the metal at the bottom of the tank. It can also cause microfractures in the glass lining. Water can then get in contact with the bottom of the tank and begin the corrosion process.

Do Dissolved Minerals in Water Cause Problems?

Yes, dissolved minerals in water allow the water to conduct electricity. The electricity accelerates corrosion of the steel water heater tank.

Distilled water, on the other hand, is virtually pure water. The distillation process removes the dissolved minerals. However, it also loses its taste. Dissolved minerals give water its taste.

Is Pure Water an Insulator?

Pure water (100 percent H2O) is actually an insulator. Electricity will not pass thru it easily.

However, water which contains dissolved minerals is a great conductor. Electricity passes readily thru this type of water. That's why household water (as well as ocean, river, lake, etc. water) poses an electrocution hazard. Almost all water in nature contains dissolved minerals.

Does Mineral Content in Water Vary?

Depending upon the source of the water supply, the dissolved mineral content can be high, medium, or low. Also, there will be different minerals present.

What Causes Electricity in a Water Heater?

The heating of water within a water heater and the motion of the water cause tiny electrical currents to be generated within the water heater. These electrical currents start to eat away at any exposed metal.

That's why water heaters have anode rods as a part of their construction. The anode rods attract the electricity like nectar attracts bees. The anode rods sacrifice themselves so the water tank doesn't corrode.

What Are Water Heater Anode Rods Made With?

These anode rods are made of magnesium. The magnesium attracts the electrical current and corrodes more easily than the steel tank. Some anode rods are made with aluminum and zinc. This type will prevent the rotten egg smell you sometimes get with a magnesium anode rod.

opens in a new windowCLICK HERE to have a replacement anode rod at your home in days.

However, if the anode rod completely dissolves, the electricity within the tank will begin to look for some other metal. That's why you need to check your anode rod periodically.

What is the Difference Between Hard and Soft Water?

Many people know the difference between hard and soft water. Hard water is water that has a high amount of dissolved minerals. When hard water is heated, some of these minerals can precipitate out of the water and form a scale on the inside of the water heater.

Can Scale Collect in a Water Heater Tank?

This scale can flake off and begin to collect on the bottom of the tank. This lowers the efficiency of the water heater by acting as a barrier to the flow of heat from the burner to the water.

This scale can also corrode heating elements on electric hot water heaters in a very short period of time. Friends of mine have had to replace electric heating elements every 3 months because of this problem.

Does Electrolysis Damage Water Heaters?

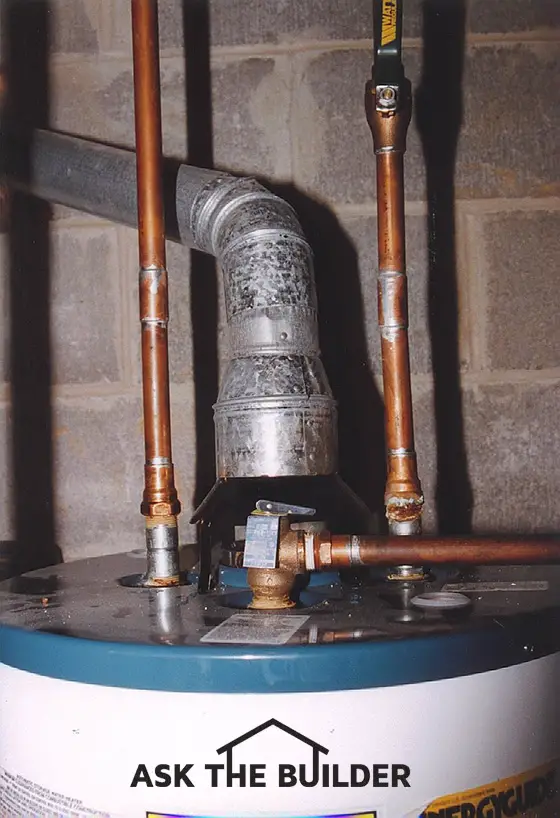

Electrolysis causes damage to your water heater tank. Iron is the primary metal used to construct hot water tanks. You can see this iron at the top of the tank where the hot and cold water pipes attach to your heater.

Often rookie plumbers or homeowners simply install a copper male adapter into the female iron tank fittings. This metal to metal contact of two dissimilar metals can lead to corrosion.

These connection points need to be isolated "electrically" from the water pipes. There are several different connectors made for this purpose. I, personally, choose to use di-electric unions. Good Luck!

This column was SO GOOD that I shared with the 31,000 subscribers who read my opens in a new windowAugust 7, 2018 AsktheBuilder Newsletter under making your water heater last.

Column B192

13 Responses to Water Heater Anode Rods