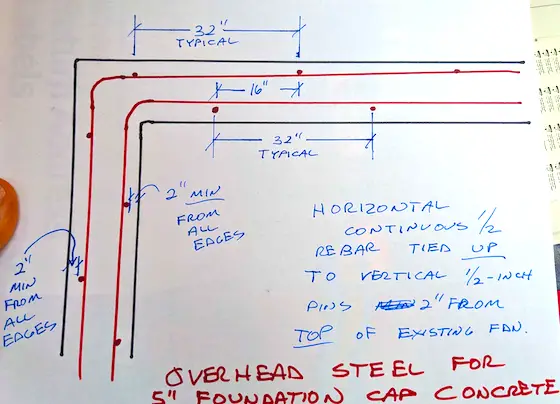

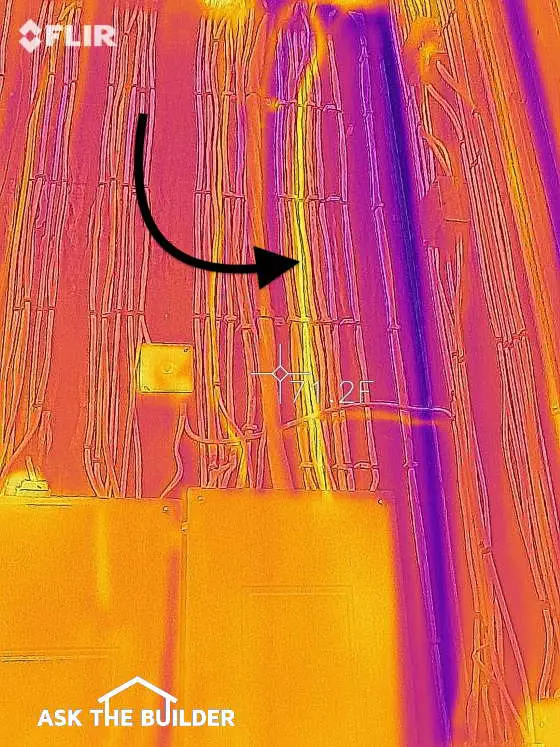

This infrared image shows a GFCI outlet that’s not being used. Your first inclination might be there’s a problem. Copyright 2024 Tim Carter

Infrared Photos of Electricity - They Could Save Your Life

I grew up reading Superman comic books. One of his superpowers was x-ray vision. He could see through opaque objects to detect danger. I was mesmerized by this power as were many children and no doubt adults.

What would you say if I told you that for less than $300 you can have a simple tool that plugs into your smartphone that transforms you into a super homeowner? I’m talking about investing in an infrared thermal imaging camera. The better ones take both photos and shoot video. Armed with one, you’ll be able to detect invisible danger lurking in your home.

Infrared Thermal Imagers

Here are a few ways an infrared camera tool can save your life and those of your loved ones. These amazing tools can tell you in seconds if electrical cables in your house are getting too hot. Circuit breakers are supposed to trip when this happens, but wouldn’t it be nice to have an extra level of peace of mind?

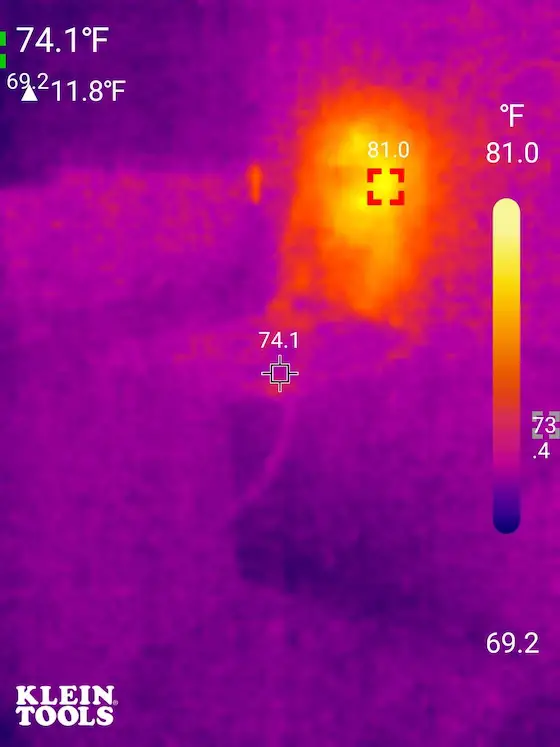

I went into my basement and pointed my infrared camera at my circuit breaker box. The image showed one glowing cable above the box while the others were all the same temperature as the panel. The glowing wire was feeding the circuit that extends to my ham radio shack. I have an electric heater running there to keep me from freezing.

The cable was a safe temperature, but it was warmer than the others. Keep in mind when lots of current is flowing through a wire in your home, it creates friction. This, in turn, creates the heat. The heater in my shack was operating and drawing about 1500 watts. I installed a 12-gauge cable to the room. This wire size is rated for 20 amps or 2400 watts. Even with that large safety factor, the cable was still bright orange in the infrared image.

I then pointed the camera sensor at a GFCI outlet in my kitchen. My coffee maker was plugged into the outlet, but it was not operating. The image showed the outlet was almost bright yellow! The image is above.

I felt the outlet, and it was only slightly warm. The electronics in the outlet that provide the ground-fault protection create this warmth as they’re constantly working and on alert waiting for you to make a mistake. There was no fire danger.

Had the same thing happened if I pointed the sensor to a regular outlet, that would be a reason for concern. A loose wire might be creating an arc that would eventually lead to a fire. You can get special circuit breakers to senes these arcs, but hundreds of thousands of homes don’t have them.

A friend of mine who lives in southern California could have used one of these thermal imagers to alert him of a problem. A few years back his wife plugged in a portable electric heater to take the chill off the room she works in. She plugged it into an outlet that is controlled by a wall switch. The switch was a dimmer that was only rated for 600 watts, not the 1500 watts the heater was requesting. Read about this dimmer switch fire.

The infrared sensor, in seconds, would have detected the overheating dimmer switch. Luckily she saw smoke drifting from the switch and unplugged the heater. Imagine if this had happen in a bedroom just before falling asleep.

This is my friend's dimmer switch. You can see how much plastic burned. You can also see some of the letters from the CAUTION warning label. Dimmers are time bombs waiting for their next victim. (C) Copyright 2016 Tim Carter via anonymous friend who is still breathing along with his beautiful wife

The infrared cameras can detect hidden water leaks or moisture that causes mold growth. Evaporation is a natural cooling process. The water evaporating behind a wall will make that part of the wall cooler. It will appear black or a dark blue on the image. You can catch mold growth before it becomes a serious health issue.

My infrared camera proves that the builder who built my house, not me, did a horrible job of insulating behind all the electrical outlets and wall switches on exterior walls. The images show all of them a deep navy blue. I wish the builder would have used spray foam between the back of the electrical boxes and the exterior wall sheathing to minimize heat loss. If you’re building a new home, be sure you make that happen.

I pointed my camera at the door between my house and unheated garage. You could see the weatherstripping was doing a poor job. Cold air was leaking past the weatherstripping on all sides of the door. It’s a small amount of air, but it adds up over time.

Sealing all the air leaks the camera points out might pay back in energy savings the cost of the camera in just a few years. Imagine using it in the summer. You point it at your ceilings to see where the insulation in your attic is causing your air conditioner to work overtime.

I’ve been testing several different thermal imagers for a few years. My favorite is one made by Klein Tools. I have the TI220. This one works with Android smartphones. If you have an iPhone, you’ll want the TI222.

I have a collection of infrared images taken at all times of years. You can view these on my www.AsktheBuilder.com website. Just type “infrared images” into the search engine on the home page. Wait until you see how hot my front door gets in the summertime!

Column 1592