Washing Machine Venting Diagram

Washing Machine Drain Vent TIPS

- 2-inch pipe for washing machine drain

- Standpipe 24 inches above p-trap

- Branch arm to vertical stack

- Relax, I'm a master plumber 😉

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

Kevin's Shortcut Vent

Kevin Garretty emailed me about a vexing problem at his Beaufort, SC home. He included a proposed drawing of what he wanted to do.

Believe it or not, he was darn close to doing it the right way.

He's scratching his head about the correct way to vent a washing machine and needs a venting diagram.

Tim's a Master Plumber

For the record, I'm a master plumber among other things. I was a master plumber at age 28 in Hamilton County, Ohio. Ten years later I sat and passed the master test for the City of Cincinnati and got my masters license.

I loved doing the plumbing on all my jobs. I think it was the challenge of the 3-D aspect of creating the network of drain and vent pipes that attracted me to the trade.

Think about it. You have one pipe leave a house to the sewer or septic system and often only one vent pipe up on the roof.

But in between, those pipes bifurcate like crazy. A master plumber needs to know how to make it all work so no sewer gas ever enters the house.

Kevin's Drawing

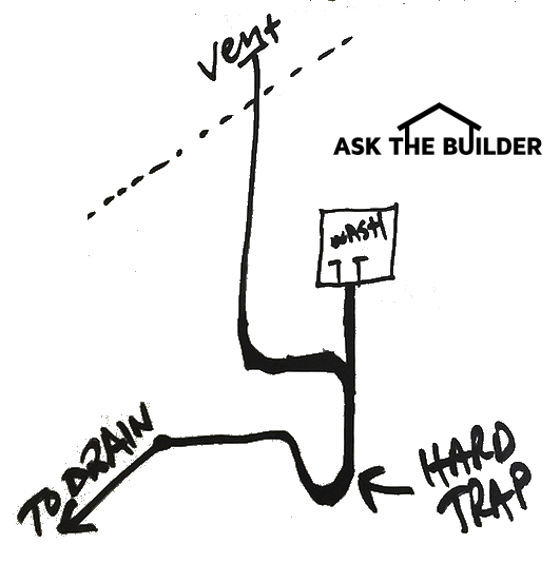

Here's what Kevin cooked up in his head.

"Is it OK to vent washer drain line, before the hard trap in the wall?"

This is Kevin's drawing. NEVER install a washing machine drain pipe and vent like this. Look at MY drawing below.

Kevin, the answer is NO.

Suction

In your scenario, if a fixture that's farther upstream discharges lots of water that rushes by the wye fitting where your washing machine drain pipe connects, the vacuum created by the water rushing past the washing machine branch Wye will siphon water from your trap.

Correct Venting Prevents Suction

If you put the vent line at the connection point of the washing machine branch arm like you see in my drawing, the vacuum pulls the needed air from the vent pipe before it tries to get it on the other side of the trap. It's looking for the path of LEAST RESISTANCE to get the needed air.

Toilets - BIG Problems!

In my diagram, I've shown a half-bathroom upstream from the washing machine. Imagine what happens when that toilet is flushed!

The rushing water fills the pipe completely and pushes the air in the pipe ahead of it towards the sewer. That air MUST BE REPLACED and as the water goes past wye fittings, it creates a vacuum at that point.

Tim's Drawing

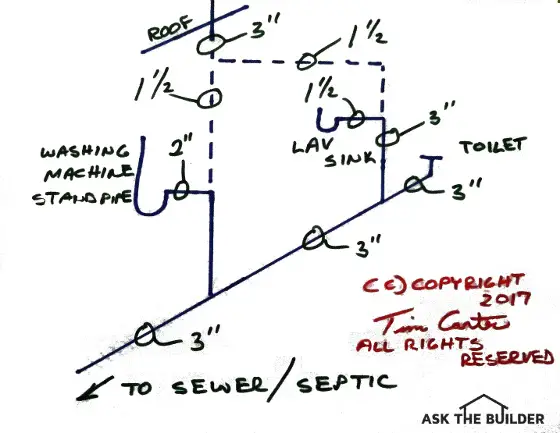

I've included the proper pipe sizes for the system. The dashed lines are vent lines and note the one vent line for the half bath is a full-sized 3-inch vent that goes up and through the roof.

The pipe that drains the lavatory sink is 3-inch in diameter because that drain line also acts as a vent for the toilet. The 3-inch pipe would never completely fill with water even if you filled the lavatory sink and pulled the stopper. This wet venting is permitted by most codes.

I've done it for years on many systems, even at my own home, and never had a suction issue if you flush the toilet and let a full sink of lavatory water drain at the same time.

Remember that vent lines MUST be sloped so they drain water towards the sewer. You never want standing water in a vent line.

Note the pipe sizes. It's very important that a washing machine has a 2-inch drain line up to where it connects to the main stack. Look at the interesting wet venting of the toilet! READ the column above to understand how it works. (C) Copyright 2017 Tim Carter - Master Plumber

Great work and thank you your diagram really hellped but now my question is what if the pre existing drain line for the washer was 1 1/2 pvc

Thanks for this great advise. I'm a do it yourself error and first response was this diagram which helped me a lot!!

Code update: the horizontal run rom a washer box has to 3 inch. It can still drain to the 4" and a 3" vent through the roof is good. (I'm glad there are no AAV's).- mechanical vents. Happy pre- Independence everyone!!!

It's the same around here too. I've asked plumbers why? No one has a convincing answer. Some have said that newer appliances have stronger pumps and the suds (generated) are a factor.

I find it difficult to believe that a three inch (horizontal) drain is really necessary on a washing machine. Sounds somewhat political to me for whatever reason(s).

I am having issues with a sewage smell backing up into my washroom....The contracter that built my addition just straight lined everything into a septic line I had run from septic tank....if there is anyone I can draw my diagram for and send it to I would greatly appreciate it....I have vented the washer and put traps on everything but still seem to get the septic smell backing into my house to the point my cloths smell like septic water....thanks in advance anyone

I bought my house 4 years ago and never had a problem til very recently. Doing a SUPER load in my GE top load 8yr old is when leaking occurs. Metal drain pipe is 2" dia, about 3' tall coming through garage concrete floor within 2 x 4 exposed studs. Facing machine, there is another ~2" dia galv pipe running floor to ceiling and through roof. There is a tapered cone shape cover that appears to install over 2" pipe coming thru roof, with a 1" opening at small end. Do I just remove cover and run a snake down it as far as it will go? This vent pipe is a min 12' tall.

Ken,

This requires one of my paid consults. Far too many moving parts in the discussion. I'm a master plumber and can get you through this.

http://shop.askthebuilder.com/products/15-Minute-Phone-Conversation-with-Tim.html

Is there a rule on proximity of where other fixtures tie in to the main sewer line in relation to the washing machine?

Should a washing machine's horizontal run (after the vent) tie in downstream or upstream of a nearby bathtub's drain (all connected via wyes).

My main sewer line runs from east to west. Tub would be south of the washing machine but is inches from the main vent stack. They would tie in to the main sewer at roughly the same spot. So, should I have the washing machine tie in first and then have the wye for the tub tie in downstream? Or vice versa?

Should I extend the run for the washing machine's drain and tie in further downstream of the sewer line?

The answer is simply "No". You can put the wye for the washing machine wherever you want it. It's all about proper VENTING.

If you want me to draw a personalized isometric drawing showing you exactly how it all should be done, you can purchase this service from me:

http://shop.askthebuilder.com/draw-plumbing-plans/

If you want to discuss all this, here's how to set up the phone call:

http://shop.askthebuilder.com/products/15-Minute-Phone-Conversation-with-Tim.html

In reply to Mark's comment back in 2016 about 3" for the horizontal arm on washer drains, see a piece in Plumbing and Mechanical Magazine by Julius Ballanco, PE. https://www.pmmag.com/articles/85477-it-s-not-the-plumbing He goes into the effect the new high-volume discharge pumps have.

Eye-opening. Some of those suckers push 21 GPM.

My washing machine standpipe overflows during washer discharge. it is 2", approx 32" tall where it enters 2" cast iron in slab (heading toward the bathtub) I dont know if there is a trap under the slab somewhere or not, but I have never smelled sewer. neither the tub nor the washer have a vent. should I try to add a vent off of the washing machine standpipe? please advise. THANK YOU SO MUCH

Yes, a vent pipe may solve your issue. If you just installed a new washing machine, some are equipped with high-speed pumps that can overload a 2-inch drain pipe.

If you have an HE front-loading washing machine, a 1 1/2" drain (and vent) will work fine due to far less water usage ( and no high-speed pump) UNLESS you mistakenly or unknowingly use a conventional non-HE detergent. They create much more foaming and will back up in the drainage system in a hurry.

I am experiencing 'gurgling' from my washing machine drain pipe. I figured it must be due to not having proper venting, but how/where to incorporate the venting?

(I am guessing the occasional water 'back-ups' could be a timely effect resulting from this as well?)

The washing machine is inside the house next to an exterior block wall (I live in South Florida).

There is a dedicated, small drain field just outside the exterior wall for the sole purpose of the washing machine to drain into (we avoided tying in the line to the septic due to the soap and detergents likely having an adverse effect on how the septic is meant to operate).

Inside the house, all along the inside of the exterior wall, we have a vertical pipe that the washing machine hose goes into; the vertical pipe is connected to a P-trap at the bottom, connected to a horizontal pipe, which elbows through the exterior wall ... on the exterior wall side, there is an elbow directed down into the ground to the drain field.

There is no sign of any vent; so, what is the best solution?

You said the lab sink had a 3” vent line and you only show it as 1.5”.

are you saying the washer drains out through the air vent?

How high does the vent pipe have to be? Right now it is has two elbows in it to go around the fascia, which interferes with future gutters (that I want to put there, but previous homeowners never had). Can I cut the pipe before it bends around the fascia to just be 7 or 8 feet off the ground, straight up? Or, if I want gutters there, should I cut it and adjust the elbows lower so it can go around the gutters?

Why use 3 inch to the vanity sink, isn’t 2 inch ok for that section of the wet vent.

I have a feeling something like this could be going on with my washing machine drain. It drains into my leach field and it doesn’t overflow every time but often. We ran water into the drain pipe via a hose for five straight minutes with no backup but the minute the washing machine drains it overflows. Not sure what our venti g system looks like as it’s in the wall. Any advise would be appreciated!