Build A Gravel Driveway

How to gravel driveway: This is a nice gravel drive on land I own. It's about 14-feet wide, it's got a deep ditch on the right side and slopes to the left. It's hard to see, but the drive has about a 5-inch crown. © 2017 Tim Carter

"It's important to realize a properly designed and constructed gravel driveway can function as a permanent driveway paving solution."

Build Gravel Drive TIPS

- Large angular base stone - 8 inches deep WATCH VIDEOS BELOW

- Geotextile fabric under base stone keeps stone free of mud

- Finish stone grape-sized with rock dust

- 5-inch crown - SEE BELOW!

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter

DEAR TIM: I need to build a gravel driveway on some land I recently purchased. Is a gravel driveway going to hold up as a permanent driveway paving solution?

What types of gravel are used for a driveway? Do you think I can construct a build-it-yourself gravel driveway? Can a dump truck spread the gravel? Ed M., Basking Ridge, NJ

How To Gravel Driveway

Watch this short video to see how a professional dump truck driver can make short work of helping you install a gravel driveway.

DEAR ED: Congratulations on your new land purchase! Over a year ago, my wife and I did the same thing with the intention of building our retirement home.

Currently, there's a rough gravel driveway that extends to the top of our property. Just last week, I was on my land to start the process of extending this gravel driveway up to our new home site.

It's important to realize a properly designed and constructed gravel driveway can function as a permanent driveway paving solution. Rent some equipment and you probably can do the job. There are hundreds of thousands, if not millions, of gravel roadways and driveways in the USA.

The first thing to remember is gravel drives work well, but come with a small number of periodic maintenance issues. But the lower initial cost of the gravel driveway is often reason enough for most to deal with whatever needs to be done to keep the driveway in good shape over the years.

Related Links

Thinking of Asphalt? Best Ones Have a Deep Gravel Base

Tar & Chip Is My Personal Preference - What Color Do You Want?

Gravel Driveway Is Small Road

The first thing I would do, if I were you, is to research basic road-building techniques. College textbooks that deal with introductory civil engineering often cover this topic very well.

A long-lasting gravel driveway needs to have all of the same design characteristics one finds in a well-constructed major roadway. You can often find great information on the Internet if you can't locate a road-building textbook.

How Do You Spread the Gravel?

The dump truck delivering the gravel can spread it. An experienced driver can put on a uniform thickness.

Watch this pro drive do an excellent job of spreading gravel on a driveway.

How Wide Should the Drive Be?

The minimum width of a great gravel driveway is 14 feet. You can make it as narrow as 10 feet, but you'll regret that over time.

Early in the process, you should think about the width of the driveway. All too often I see gravel drives in wooded areas that are not only too narrow, they often have turns that are too sharp.

You should make the drive no less than 14 feet wide. If the drive is long, think about what happens if two cars meet each other going the opposite direction. You may want to widen the drive for 40 feet in places to 18 feet so two cars can pass without going off onto a soft shoulder.

Think ahead about delivery trucks and moving trucks. Don't make turns too tight. Gradual curves are best. Don't have trees next to the inside part of a curve as a long truck could scrape against it.

How Do You Create Great Drainage?

You create great drainage by including small ditches along the driveway to transport water away from the driveway.

A point often overlooked is the soil under the gravel driveway must be well-drained and strong. It also must be free of any organic material like sticks, tree roots and leaves or grass.

All topsoil must be stripped off the driveway location and stockpiled for use at some other place on your lot. It is a very bad practice to build a driveway on top of spongy topsoil filled with organic debris.

Water is the enemy of gravel driveways and any roadway. Surface water can erode the gravel off the surface of the driveway and subsurface water can turn strong subsoil into a quagmire.

Does the Gravel Need a Crown?

Yes, gravel driveways need a crown. A crown is a curved shape where the center of the driveway is higher than the edges. A crown promotes great drainage and prevents washouts.

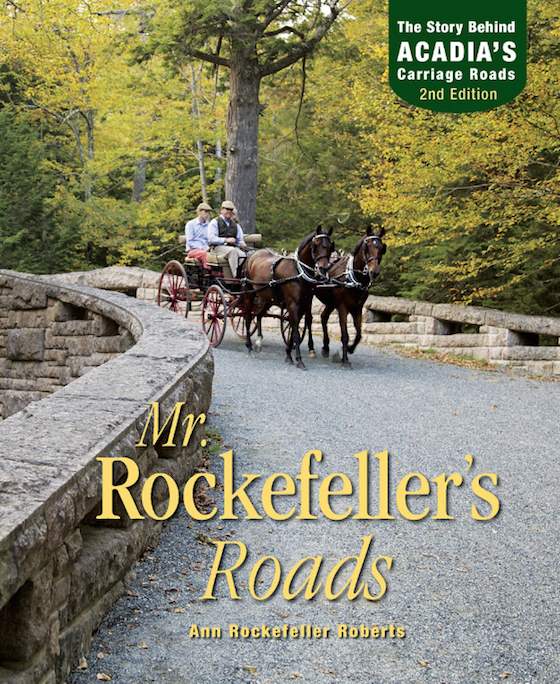

John D. Rockefeller, Jr. constructed nearly 60 miles of stunning gravel carriage trails on Mt. Desert Island in the 1920s and 19030s. Not only was he a gifted road designer, but he also had enough practical knowledge to create an 8-inch crown on all his gravel trails.

A crown refers to the profile of the road. The center of each carriage trail was 8 inches higher than the edges of the road. Crowned roads deflect water to the edges thus preventing ruts and erosion on the roadbed.

Be sure you have at least a 6-inch crown in your gravel driveway.

Here's a tiny section of the carriage trails on Mt. Desert Island. This is a great book. CLICK THE PHOTO NOW to have it delivered to your doorstep.

The weight of cars and trucks pressing down on a gravel driveway is not much different than the powerful hydraulic pressure used on construction machinery, car lifts and any other machine that uses the leveraged force of hydraulics.

Water that is forced under pressure under the gravel can transport silt from the subsoil into the gravel. As the silt squeezes between individual pieces of gravel, it causes the friction bonds between individual pieces of gravel to weaken. When this happens, your gravel driveway can fall apart in no time.

Do I Need Geotextile Fabrics For a Gravel Drive?

Yes, it's often a great idea to install a geotextile fabric on top of the subsoil before the first layer of gravel is installed. This fabric prevents the silt in the subsoil from fouling the gravel. These products come in wide rolls and can easily be installed by two people who just unroll the fabric allowing it to lay on the soil.

This is a giant roll of geotextile fabric. If the soil in your area is clay, you MUST INSTALL one. CLICK THE IMAGE TO ORDER THIS FABRIC NOW.

On windy days it needs to be covered quickly with a 4 or 6-inch-thick layer of crushed gravel. If you don't do this, the fabric might end up on your neighbor's lot.

What Type of Gravel Should Be Used?

A gravel driveway requires several different types of gravel.

The first layer of crushed gravel needs to be a larger-sized gravel. Try to locate stones that are the size of baseballs or even softballs.

Watch this short video to see the size of the first layer of stone that goes down first then the size of the gravel that goes down on top of the larger stones:

CLICK THE IMAGE to watch a short video of the correct-sized stones to use in a gravel driveway. Copyright 2018 Tim Carter

NEVER use pea gravel or rounded river rock gravel. These stones are like ball bearings and will easily roll and move as tires start to spin. A car or truck can never stand a chance going up a hill with rounded gravel as the wheels would spin like a top. Angular gravel interlocks with adjacent pieces and the combined mass can act as one larger piece of rock.

Driveways get their strength from the base layer of stone. If you want a driveway that will stand up to large heavy trucks, then this first layer of stone needs to be 8 inches thick. Two 4-inch layers with each one compacted would be good.

What is the Best Gravel for the Top of the Driveway?

The top layer of gravel should be crushed gravel that has a mixture of pieces in these sizes:

- 3/4 inch

- 1/2-inch

- 1/4-inch

- crushed fines (looks like sand)

The top finish layer should be about 4 inches thick.

Compact each layer with a mechanical roller or tamping machine. The final layer of gravel should have pieces of angular stone no larger than a golf ball, with many of the stones being the size of marbles or grapes.

If you can install 10 - 12 inches of gravel on top of the geotextile fabric, you should have a gravel driveway that will last decades.

Will a Crowned Gravel Drive Prevent Washouts?

Yes, a crowned drive will prevent washouts. The crown directs surface water to the edges.

Drives without crowns tend to channel water in the drive. Soon a rut or channel erondes the gravel.

Be sure the gravel driveway has a crown in it. This means the center of the driveway is always higher than the two edges. The crown allows water to flow off to the sides of the driveway preventing any ponding of water on the gravel surface. A 5-inch crown is one where the center of the driveway is 5 inches higher than the edges. It will do a superb job of getting water to the edges of the road quickly.

A crowned driveway also helps prevent washouts. The worst profile of a driveway on a slope is one where the center is lower than the edges. If your drive is shaped like this in a heavy rain you'll have a wild river racing down the center of your driveway washing away all your expensive gravel.

This is a gravel drive just down the street from where I live. The center of the drive has always been lower than the edges. Each time there's a heavy rain, this is what it looks like when the sun comes out. The owner then has a tractor take the gravel back up the hill to create the same problem again. © 2017 Tim Carter

How Do you Smooth a Gravel Drive?

You use a york rake attachment on the back of a tractor to smooth gravel driveways.

Gravel driveways need some periodic care in the form of grading or dressing. Low spots need to be filled with gravel scraped from any high spots. If your driveway has curves, you will discover that car and truck traffic tends to push loose gravel to the outer edges of the curves. This gravel needs to be brought back to the center and inner part of the curves.

Farmers have an attachment for their tractors that comb gravel drives. It's called a york rake. They work great. You can also use a similar tow-behind grader that has carbide teeth.

Watch both short videos below.

Do you Need Culverts & Ditches?

Gravel driveways built on hillsides need ditches on the high side of the driveway. These ditches capture surface water that runs down the hill and otherwise would run across the driveway.

Larger angular rocks should be placed in the ditch to slow down the speed of the running water in the ditch. Monitor the ditch to ensure the running water is not cutting too deep a channel or eroding the ditch causing failure of the gravel driveway.

Check the May 19, 2011 AsktheBuilder Newsletter for a great tip when making your gravel driveway.

Author's Notes:

Leo Kudej of Haymarket, Virginia, offers these comments from his years of experience.

"Tim,

I think you need to tell the readers just what they need to apply to the roadbed layers. This way they can just call into their local quarry exactly the type of stone they want.

The build-up should go as follows - the first layer will be #3 stone (fist size); the second will be #57 (a little less than ping pong ball); and the final will be #21-A, or called crusher run (thumbnail sized stone with stone dust mixed in with it).

With a layered setup like this, you will have a driveway that will last many, many years. I am a carpenter, but living up on Bull Run Mountain for 20 years taught me a little about gravel roads." Leo K.

Column 698

29 Responses to Build A Gravel Driveway