How to Drill Ceramic Tile

Drilling ceramic tile requires a sharp carbide or diamond drill bit. Drilling into tile requires a slow drill speed and a steady hand. © 2018 Tim Carter

"Real porcelain tile is very hard. Porcelain tile almost always has a high silica content and the tile is dense."

How to Drill Ceramic Tile TIPS

- Drilling ceramic tile requires a carbide bit

- Porcelain tile is the hardest

- Drill slow - use special drill-bit cooling oil

- Diamond drill bits are inexpensive

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: Drilling ceramic tile just became a priority. My wife wants me to install several new towel bars and other accessories in an older bathroom.

I also need to install anchors for a new shower door. I tried drilling into the tile but got nowhere fast.

The drill bit smoked and turned cherry red. I need to get this job done before my wife comes back from her business trip. Help me, Tim, you're my only hope. Jonathon O., Los Angeles, CA

Related Links

Cutting Ceramic Tile - Pro Tips

Ceramic Tile Snapping Cutter - Big Tile

DEAR JONATHON: Buddy, you are going to owe me big time. I am going to make you look like a home-improvement super hero. But to do so, you might have to buy a new drill and a few special drill bits.

Why is Ceramic Tile Hard?

Ceramic tile is hard because it's artificial or man-made rock. Any geologist will tell you that some rocks are far harder than others. The same is true for ceramic tile.

Free & Fast Bids

CLICK HERE to get FREE & FAST BIDS from local tile contractors who can drill your tile for you.

What Tile is the Hardest to Drill?

Porcelain tile is the hardest tile to drill.

Real porcelain tile is very hard. Porcelain tile almost always has a high silica content and the tile is dense. If the manufacturer fires it at a hotter temperature for longer in the kiln, the silica-rich clay gets almost as hard as granite.

You might have tried to drill a hole in porcelain with the wrong drill bit and you were drilling far too fast.

What Makes Porcelain Tile So Hard to Drill?

The heating process inside a kiln makes the porcelain tile hard to drill. The high temperature in the kiln modifies the chemistry and crystallography of the silica-rich raw material.

Just like an oven changes liquid batter into cake, the higher kiln temperature transforms the putty-like clay into artificial stone. In the early stages of tile manufacturing, the clay that's used to make the tile is a putty.

Some you can form with your hands but other clay can only be molded by a machine it's so stiff. But when it get's heated, the crystal structure changes and it transforms much like plastic concrete in a read-mix truck turns hard hours after it's poured or cast.

Why Is Porcelain Tile Hard to Snap?

The high silica content of porcelain tile also makes it nearly impossible to cut with a snapper-type tile cutter. The tile often shatters with conchoidal fractures like glass.

Why Does the Tile Glaze Make Drilling Into Tile Difficult?

The shiny glaze on the tile is glass and glass is slippery. The tile drill bits slide around on the tile making it hard to keep the drill bit in place.

Many common ceramic tiles are made primarily with clay, but then coated with a thin glaze that is primarily silica. In the kiln, this silica coating turns into a hard, thin glass coating and the clay transform into a low-grade slate-like rock.

Once a drill bit penetrates the thin glass coating, it usually drills rapidly through the inner core of regular ceramic tile. The inner core of these tiles is fairly soft.

What Tile Drill Bit is Used?

The key to drilling regular ceramic tile is to use a brand-new carbide-tipped masonry drill bit and a drill that has a variable-speed trigger. You never want to drill ceramic tile with the drill at high speed.

What is the Best Tile Drill Bit Speed?

The lowest tile drill bit speed possible, say 100 or 200 revolutions per minute, is perfect to drill standard ceramic tile. Apply moderate even pressure to the drill so the bit grinds away at the glaze or the tile. If you drill fast, you'll overheat the drill bit and ruin it.

Should I use a Hammer Drill Drilling Into Tile?

Never use a hammer drill for ceramic tile. You'll shatter or crack a ceramic tile if you drill using the hammer function. Hammer drills are fine for brick or concrete, but not ceramic tile.

CLICK HERE to get FREE & FAST BIDS from local tile contractors who can drill your tile for you.

How Do You Prevent Scratching Tile?

You prevent scratches on tile by applying light pressure with the drill.

The biggest mistake you can make when first starting to drill into a tile is applying too much pressure. The drill bit can slip on the highly-polished glazed-tile surface, and the bit will slide possibly creating an ugly scratch.

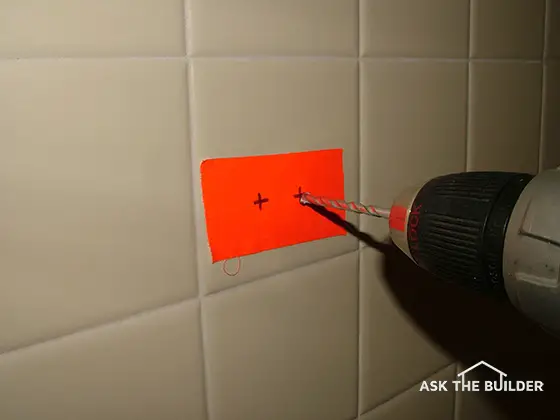

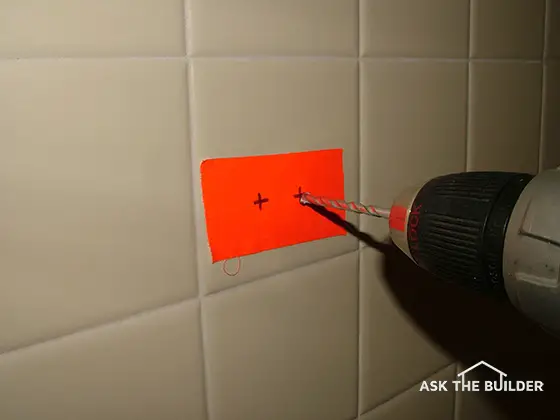

I always placed a piece of duct tape over the spot where I want to drill. I then marked the hole center point on the tape, and begin to drill. The tape does a good job of controlling a wandering drill bit, and it offers scratch protection should the bit slide.

Why Does the Drill Bit Smoke and Get Hot?

Your drill smokes and gets hot because you were drilling too fast. This creates enormous friction which causes rapid heat build up. Slow drill speeds do not create as much heat.

IMPORTANT TIP: You can keep the drill bit cool by dipping it in a small container of fresh cutting oil every 15 - 30 seconds. After dipping the bit in the oil for a few seconds, wipe the bit off with an old rag to keep the tile and grout oil-free. You can buy this special oil at a plumbing supply house. Plumbers use it to keep pipe-threading dies cool.

This is a fantastic cutting oil that can keep your drill bit cool. Drill for 20 seconds then dip it in a small tube filed with the oil. CLICK THE IMAGE NOW TO BUY THIS OIL.

Is a Diamond Tile Drill Bit a Good One to Use?

Yes, a diamond tile drill bit is a great one. Diamonds are extremely hard and cut through the glass tile glaze fast.

If you do have to drill porcelain tile, buy special drill bits that have diamond tips. These bits must also be kept cool with cutting oil, and you must drill slowly to minimize heat buildup. Once the drill bit starts to cut a cone-shaped hole into the tile, the drill will make good progress.

Here's a set of diamond drill bits that can drill holes of different sizes. You can also get much larger hole saw bits too. CLICK HERE TO ORDER THEM OR SEE OTHERS.

How Do You Cut Holes in Tile?

Large holes in ceramic tile can be created any number of ways. You can purchase hole saws that have diamond-cutting surfaces.

To drill into existing tile, the hole saw must be equipped with a pilot bit that drills a smaller hole into the center of the larger hole. This pilot bit keeps the larger bit from wandering.

If you have to drill a tile that has not been installed and don't have the tools nor inclination to drill the large hole, take it to a shop that fabricates granite or marble countertops. They have all of the bits and equipment to drill any sized hole.

I used a service like this to drill holes into three pieces of granite tile for my daughter's bathroom. To ensure the holes were drilled in the right places, I covered the face of the granite tile completely with wide masking tape. I then drew the perfect circles in the right locations on each piece of granite. The fabricators did a fantastic job of drilling the holes and all worked perfectly when I installed the granite.

CLICK HERE to get FREE & FAST BIDS from local tile contractors who can drill your tile for you.

Author's Note:

In a Reader's Comment, Mark asked about drilling a 1/2 hole in his kitchen sink for a water dispenser. His sink is porcelain with cast iron underneath.

Gregg W. of Stevens Point, WI, emailed a helpful answer to Mark's question.

"Just happened to see your answer regarding drilling through a porcelain/cast sink to provide a faucet hole.

I've had considerable experience with all types of cast iron in an industrial setting. It isn't hard to drill or tricky but bits do tend to wander in cast if not held rigidly.

My suggestion would be to start with a masonry bit as in drilling tile and then switch to a normal HSS bit after it is obvious you're through the surface. Use the tape trick. I drilled the hole for, and installed a filter tap hole, this way first time without any problems. I used a 3/4 HSS bit with a 3/8" shank. A hole saw might wander far and wide on this surface. Pilots for hole saws are usually HSS and not the best at that."

Related Column:

Column 674

6 Responses to How to Drill Ceramic Tile