Drywall Cutting Tools and Tips

How to cut drywall you ask? Here are three nifty drywall cutting tools to help cut drywall. The smallest one is the most ingenious and it's new technology. ©2017 Tim Carter

"He was attacking the drywall with a circular saw creating so much dust that I thought the EPA was going to issue a county-wide air quality alert."

Drywall Cutting Tools Checklist

- Razor knife is all-around best tool

- Spiral saw for pros

- A special reciprocating saw blade

- Dust shield for circle cutter

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: I'm a remodeling novice, and am going to be doing some drywall work soon. I've never worked with the material and have no idea how to cut it.

Not only do I have to cut new sheets to size, but I also have to make cutouts in existing drywall walls and ceilings. A friend suggested I use a circular saw. That makes sense to me.

What tools and techniques do you use to cut drywall? I'm interested in both accuracy, speed and safety. Rachel C., Tacoma, WA

DEAR RACHEL: I clearly remember one weekend driving to a potential customer's house to look at a job. His next door neighbor had a sheet of drywall laying flat on two sawhorses out on his driveway.

Can a Circular Saw Cut Drywall?

A circular saw can cut drywall, but it creates far too much dust. The dust is hard on your lungs and it's hard on the moving parts in a circular saw.

He was attacking the drywall with a circular saw creating so much dust that I thought the EPA was going to issue a county-wide air quality alert. Suffice it to say I offered this man the some of the same advice I'll offer to you.

First, don't use a circular saw to cut drywall. It's like using a rock to hammer nails. Both are the wrong tools for the job.

CLICK HERE to get FREE & FAST BIDS from local drywall hangers in case you don't want to get dusty.

A circular saw creates giant clouds of unnecessary dust. This dust causes premature wear on the moving parts of the saw, as well as your lungs and those standing nearby.

How Do Pros Cut Drywall?

Professional drywall hangers use a regular razor knife to make straight cuts on drywall. Standard drywall, or sheetrock, is simply a sandwich product.

This is my FAVORITE razor knife of all time. I've used countless ones and this fits my hand perfectly. You'll never allow anyone to use it once you use it. CLICK THE IMAGE NOW AND BUY TWO OF THEM. You'll hide the second one in case you lose the first one.

This method creates little, or no, dust. That's a good thing.

It's comprised of two outer layers of special paper that conceal a gypsum-based core. Each drywall manufacturer might have a special recipe of ingredients found in the core, including a high-purity synthetic gypsum that's recovered from the flue gasses that are emitted from coal-fired power plants.

Is Drywall Dust Unhealthy?

The fine dust created by a spinning saw blade cutting through the gypsum core in drywall is not healthy for you or your power tools. Spinning saw blades work well with wood because they normally create a harmless dust for the most part.

What is Score & Snap When Cutting Drywall?

Scoring drywall means cutting into the paper facing on one side of the drywall panel. A sharp razor knife will cut through the paper with one stroke.

To cut a straight line with drywall and create minimal airborne dust, you just score one side of the drywall with a sharp razor knife. Apply enough pressure to completely cut through the paper and into the gypsum core about one-eighth inch. You need to cut this line all the way across the piece of drywall from edge to edge.

How Do you Snap a Piece of Drywall?

After making the cut, you go to the other side of the drywall and apply pressure directly behind the cut line. This pressure causes the drywall panel to snap along the cut line and bend over completely on itself.

You finish the cut by simply cutting through the paper backing on the other side of the drywall panel.

How Thick is Standard Drywall?

Standard drywall is one-half-inch thick. You can use this method to cut off pieces as narrow as one and one-half inches wide. If you need to cut narrower pieces from a sheet of drywall, it requires you to make deeper cuts with the razor knife into the gypsum core.

Do this carefully so the razor knife cuts only the drywall and not you.

CLICK HERE to get FREE & FAST BIDS from local drywall hangers in case you don't want to get dusty.

What's the Best Power Tool To Cut Shapes and Holes?

A RotoZip Saw is what professionals use to cut shapes and holes in drywall. It's extremely fast.

This is the dream tool for all drywall hangers. All pro hangers have one because it increases their productivity by a factor of 10X or more.

This is an amazing tool invented decades ago. It cuts holes in drywall accurately and FAST. CLICK THE IMAGE NOW TO ORDER ONE. Get EXTRA spiral bits.

This tool comes with special bits that have cutting edges on the spiral twist of the shaft. You'd think they were just regular drill bits, but you'd be wrong. You need to cut counterclockwise with these around electrical boxes or the tool will spin right into the drywall!

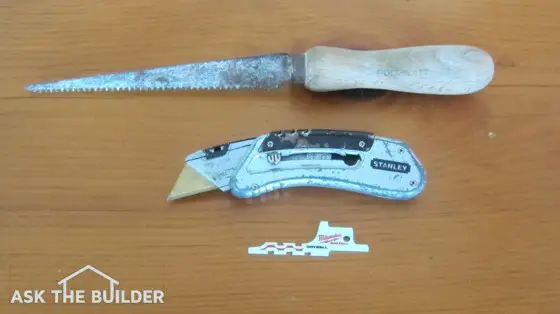

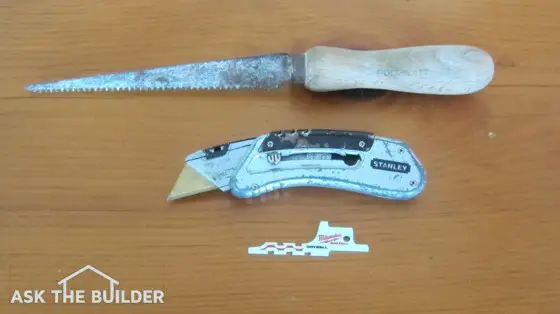

How Do You Cut Holes By Hand?

A hand, or jab, saw is a great tool rookie or DIYrs use to make square, rectangular, or circle holes in drywall. I've used one for years. You'll discover quickly to apply pressure on the push stroke so you don't create jagged edges on the paper with the pull stroke.

Keep in mind these blades are normally about 5 or 6 inches long and they can easily reach wires, cables, pipes and other things hidden behind the drywall. A rookie like you can easily create big and expensive repair problems in a hurry using one of these tools.

Use this tool with great care if you're cutting into drywall already attached to a wall. If you're cutting new drywall that's standing up next to you on the stack, cut away post haste!

How Can You Safely Cut Into Existing Drywall?

You can cut safely into existing drywall using a special dull small blade that fits into a reciprocating saw.

To make cuts into existing drywall that's screwed or nailed to walls or ceilings, you can make repeated cuts with a very sharp razor knife, but it's very time consuming and hard to do. The gypsum core creates a large amount of friction making the cutting difficult.

It's far better to use a new short metal blade has been developed for electric-powered reciprocating saws that's designed specifically to cut holes into existing drywall.

Here's a new drywall cutting blade that fits in an electric reciprocating saw. It's perfect for cutting holes in drywall on walls and ceilings but not the things hidden behind the drywall! CLICK THE IMAGE NOW TO BUY THIS GREAT BLADE ©2017 Tim Carter

The blade has a blunt tip, and it's only about one and one-quarter inch long. It doesn't have sharp teeth, but rather square notched cut outs.

It does a splendid job of cutting drywall, but won't cut deep enough to harm anything behind the drywall, especially if you hold the blade at a 45-degree angle as you glide it across the surface of the drywall.

Is It Dangerous to Cut Holes in Ceilings?

Be careful when cutting holes in drywall ceilings. Always wear safety goggles, not safety glasses. Drywall dust and small chunks of gypsum core in your eyes can cause you to make an expensive trip to an emergency room or eye doctor.

Professional drywall hangers use a small rotary cutting tool fitted with a bit that looks like a standard drill bit. This bit has special cutting edges on the spiral shaft that allow it to cut rapidly through drywall.

You want one that comes with the dust shield. They work well to capture the dust that otherwise would float in your eyes and around the room.

These tools are used by every professional drywall hanger that I know. While they increase production by a factor of five or more, they also create small clouds of dust.

How Do you Smooth the Rough Snapped Edge?

Use a hand rasp to smooth the rough snapped edge of drywall.

When you score and snap drywall you can end up with a rough edge. This handy tool cuts away the gypsum core in seconds allowing you to have a nice fit and no issues with a piece that's an eighth of an inch too BIG!

If you're a perfectionist and want tight-fitting pieces, you'll NEED this tool. CLICK THE IMAGE NOW TO ORDER ONE.

Author's Note: Rob Crangle sent the following email regarding fly ash in drywall.

"Hi Tim,

Enjoy reading your articles. Just finished your article on drywall cutting techniques.

Your concerns regarding fly ash are quite valid. I'm the Gypsum Commodity Analyst at the US Geological Survey. About half of the country's drywall is made of synthetic gypsum, most of which comes from coal-fired electrical power plants, where, indeed, a lot of fly ash is also produced. Thankfully, almost none of that (I'd say zero, but there's likely a lab technician out there who would find a trace of it and make me a liar) ends up in the synthetic-gypsum production stream.

Agree that it's not a good idea to inhale large quantities of drywall dust, but that dust, even if the gypsum originated from a coal-fired plant, probably contains little to no fly ash.

Best,"

Rob Crangle

CLICK HERE to get FREE & FAST BIDS from local drywall hangers in case you don't want to get dusty.

Column 977

11 Responses to Drywall Cutting Tools and Tips