Paperless Drywall

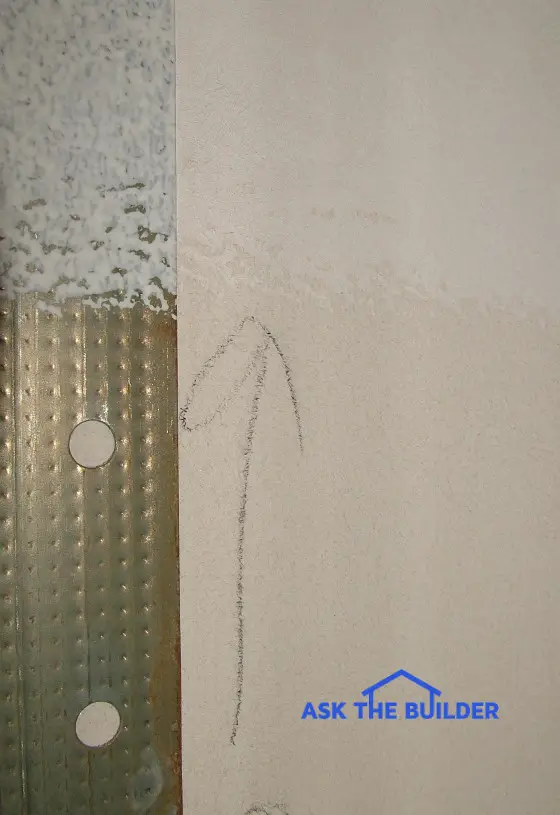

It is really hard to see, but the paperless drywall in this photo has a texture like ultra-fine steel wool. PHOTO CREDIT: Tim Carter

Paperless Drywall TIPS

- Many different types of drywall some with no paper

- Inner gypsum core is different and more resistant to water damage

- Slightly rougher texture easily made smooth by skim coating

- Use in high-humidity locations of home

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: Paperless drywall is causing me some consternation. Is it as easy to cut, install and finish as traditional drywall that has a paper facing?

Why would I want to use paperless drywall? The texture of the paperless drywall is definitely rougher, and I am worried the walls and ceilings in my house will not be smooth.

Would you use this paperless product in your own home? Joy B., Olive Branch, MS

DEAR JOY: The paperless drywall is a fascinating product.

Great For Wet Locations

To me it is one of those, why-didn't-I-think-of-that products. While traditional drywall with paper facing is fine in many instances and I have it on virtually every surface of my own home, the paperless drywall solves a few pesky problems the paper-faced drywall has had for years.

Paper Sandwich

Traditional drywall has a firm gypsum core that is wrapped with special paper both front and back. Not all drywall has the same paper facing.

Some drywall products have colored paper facing (blue or green) that inhibits the absorption of water that might otherwise soften the gypsum core.

Free & Fast Bids

Fiberglass Is Immune To Water

The paperless drywall is covered both front and back with fiberglass which is naturally highly water resistant. It also comes with a moisture-resistant gypsum core. Not all traditional drywall has this type of core.

Slows Mold

First and foremost, the paperless drywall was created to help minimize the spread of mold in homes.

Is it mold-proof? Absolutely not. It's mold resistant simply because the fiberglass mat that replaces the paper is not a known food source for many common molds.

Some molds actually feed on the paper facing of traditional drywall if the drywall becomes wet or damp and stays moist.

I Loved It

I have used this paperless drywall on two recent projects in my own home. Aside from the slightly rougher surface when handling it, I could tell no other difference when cutting the paperless drywall with a traditional razor knife.

Drywall screws and nails penetrate the paperless drywall just like traditional drywall.

View From A Distance

When viewed in daylight at a distance over six feet away, the surface of the paperless drywall appears nearly identical to that of traditional paper-faced drywall. But when you get closer and look at the surface of the paperless drywall, you can see and feel the fine fiberglass matting.

At night when light washes down a wall from above at a low angle, the texture of the fiberglass matting is very apparent.

Finishing Fills Texture

If a rookie drywall finisher and painter work on the paperless drywall, you might see smooth polka dots where the screws and nails are covered with finishing compound in the drywall.

Smooth racing strips might also be visible at corners and flat seams where joint compound and tape was used to finish the unsightly seams where two pieces of drywall touch one another.

The smooth areas are created when the creamy joint compound fills the small voids in the fiberglass matting. The filled glass matt has a very different texture than unfinished paperless drywall.

Simple Skim Solution

This problem is easily solved if the entire surface of the paperless drywall is skim coated with drywall topping compound. There are many different methods of skim coating as well as large tools to make the job go faster.

One method, that has worked well for me, is to add some water to drywall topping compound transforming it into a thick paint. Apply the topping compound to the paperless drywall with a thick-napped paint roller, and then immediately remove it with a wide flat knife. If the humidity is low, the skim coat dries very rapidly.

Skimming Last Step

It's best to skim coat the paperless drywall after it has been sanded. The skim coat offers a secondary benefit of fixing minor imperfections that might appear in the drywall finish.

Use In High Humidity Locations

The paperless drywall can be used in bathroom areas where you might expect high humidity, but not necessarily water contact. An example of this would be exposed wall surfaces above ceramic tile in tubs and showers, around vanities and toilets, etc.

The paperless drywall can be used in any other part of the home where you might otherwise use traditional drywall. It has one slight disadvantage. The drying time of finishing compounds is slightly slower.

This stems from the fact that the fiberglass matt facing allows little or no water to penetrate in towards the gypsum core. When using traditional paper-faced drywall, the water found in finishing compounds can soak into the paper allowing for more-rapid drying times.

Column 688

15 Responses to Paperless Drywall