Roof Flashing Repair – Don’t Use Caulk

Roof Flashing Repair | The brown-red strip is a sill flashing. It has a bend in it and extends up behind the wood siding. The siding and the flashing act just like the shingles below. All overlap one another just like the shingles on the roof.

DEAR TIM: I have a simple sloped roof over a side porch on my new home Each time it rains, water leaks down the wall of the porch. The vinyl siding above the roof simply touches the shingles and there is some caulk that has pulled apart. Can I stop the leak by adding more caulk? Is there a more permanent solution? Demise L., Beckley, WV

DEAR DENISE: Oh my! In my opinion, caulk is not an acceptable substitute for traditional metal roof flashings. Don't use caulk for roof flashing repair. Certain caulks are highly weather resistant, but they can fail if there is too much movement between the roofing materials and the things that are not roofing such as your vinyl siding.

Does Vinyl Siding Expand and Contract?

Vinyl siding, for instance, has an enormous expansion / contraction coefficient. This simply means that as the temperature of vinyl siding goes up and down during the day and night, it expands and contracts dramatically. This movement can and does break the bond between the siding and the caulk or the caulk and the shingles.

What is a Roof Flashing?

A roof flashing is something that connects roofing materials to something that isn't a roofing material. Here are a few examples of something that a flashing touches:

- plumbing vent pipe CLICK to watch video!

- B-vent from a heater or furnace

- dormer wall

- chimney

- the side wall of an adjacent building

Do Roofers Make Flashing Mistakes?

The roofer that worked for your builder made an enormous mistake by not installing a simple metal flashing that should have covered over the top of the last course of shingles and then continued up the vertical face of the wall. This metal flashing piece is normally eight inches wide and perhaps ten feet long. Four inches of the metal laps over the shingles and the remaining four inches extends up the wall. If the roof is longer than ten feet where it butts up against the house, two or more pieces of flashing are overlapped and soldered to make one large continuous flashing.

Avoid repairing roof leaks yourself! Find a professional using my Roofing Replacement / Repair Checklist. I offer a 100% Money Back Guarantee.

How Do You Make Flashings?

Virtually all professional roofers own a tool called a metal brake that enables them to quickly create a crisp bend in the metal flashing that matches the angle of the roof where it meets the house. They typically add a second small bend of about ten degrees one-half inch in from the edge of the metal that overlaps the shingles. The addition of this second break or bend takes the waviness out of the metal that often happens when the metal is cut using a traditional metal-cutting scissors or snips.

WATCH THIS VIDEO to see a flashing with a similar kick-out bend:

Can A Metal Brake Be a Cutting Guide?

You can minimize or eliminate waves in the metal when cutting sheet metal such as tin or aluminum if you use the metal brake tool as a cutting guide. When I had access to a brake and had to cut sheet metal, I would insert the piece of metal into the brake tool and push the clamping lever to lock the break's jaws down on the sheet metal. Using a razor knife equipped with a new blade, I would make score the metal along the top jaw of the break. The razor would actually cut partially through the metal and when the brake handle was rotated up and down several times, the metal would separate much as the pop tab on an aluminum drink can breaks when bent back and forth.

This is a soldered seam between two pieces of the 40 pound tin. You can also clearly see the edge that has been created with the break. This bend in the metal actually keeps the metal very straight.

Where Do You Find Most Roof Leaks?

Ask any professional roofer and they will often tell you that flashings are the source of over 90 percent of roof leaks. Unfortunately, many rookie roofers or ambitious do-it-yourselfers do not fully understand how flashings should be made and how they work.

The flashing that is missing at your home will work because it acts just like the shingles below it. The flashing overlaps the shingles and then extends up the wall of the home. The vinyl siding then overlaps the metal flashing. Each successive piece of vinyl siding overlaps the one below it. This overlapping system of materials does a fantastic job of stopping water.

CLICK or TAP HERE to get FREE quotes from local companies that can install your roof flashings.

What are the Best Flashing Materials?

Great roofers readily understand and see this and they know the correct materials to use. Look at professionally installed flashings and you will rarely see caulk. Solder is the product of choice to permanently seal seams and small holes created while overlapping and bending flashing metal around chimneys, dormers, wall corners, etc. that are routinely encountered when roofing materials touch up against things up that periodically penetrate a roof.

Should Aluminum Flashing Be Used With Brick?

Not all flashing materials can be used universally up on a roof. Aluminum works well in many locations, but should not be used in contact with masonry of any type. The alkaline chemicals in mortar can react with the aluminum and cause corrosion.

What About Tin and Copper Flashing?

Tin used to be available in different weights. 20 and 40 pound tin are the most common. I prefer 40 pound tin as it lasts much longer. However, harsh regulations imposed by the EPA have made it just about impossible to find tin-coated steel. It's a regulation I disagree with and is not based on solid science.

Copper, of course, is the premier flashing material. It can last up to 100 years without failure and is as easy to solder as tin. Galvanized metal and sheet lead can also be used, but they are more difficult to work with.

What About Using Thin Stainless Steel Flashing?

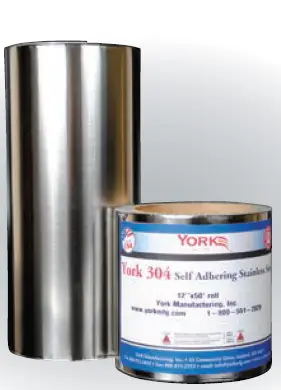

Thin stainless steel is a great flashing material. It's easy to bend and some come with self-adhesive backing for uses on walls and under doors and windows.

This is a fantastic stainless steel flashing you can mold yourself to fit any brick sill opening. CLICK on THE IMAGE NOW TO ORDER THIS AMAZING NO-RUST PRODUCT. York 304 stainless steel flashing

Read my January 13, 2013 AsktheBuilder Newsletter for a shocking article on using caulk with copper flashing! This was one of the finest home improvement magazines.

Column 529

6 Responses to Roof Flashing Repair – Don’t Use Caulk