Sheet Vinyl Woes

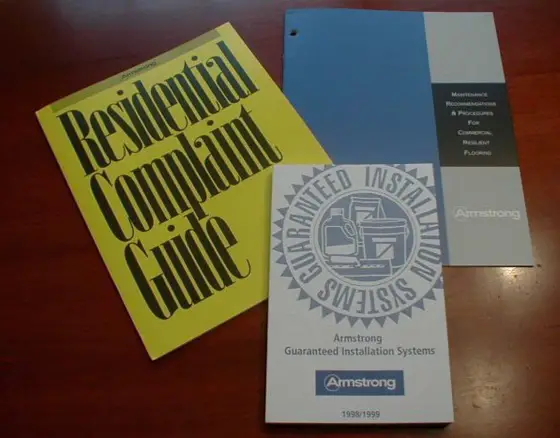

These are actual flooring installation manuals published by the flooring manufacturers. They contain specific step-by-step instructions as well as exact products to use that compliment the flooring.

DEAR TIM: Three months ago, I had a new sheet vinyl floor installed. There are stains that seem to be deep within the vinyl and several seams are cracking. What's more, there seem to be spongy spots in the floor when I walk in certain places. The flooring was installed by a friend who is a serious do-it-yourselfer. He installed a new underlayment. Do you think the problems are his fault? How can I keep the floor looking great? Sandy J., Roseburg, OR

DEAR SANDY: Uh Oh... You are probably going to have to make an uncomfortable phone call. There is a very good possibility that all of your current problems can be traced to workmanship or unapproved material usage errors. I think you are going to be forced to do an autopsy on the floor to discover the source of the problems.

Sheet vinyl flooring requires a tremendous amount of skill and training to be installed properly. The major sheet vinyl manufacturers offer extensive factory training for full time professional installers. In addition, they have detailed instruction guides and specifications for each of their flooring products. If these are not followed you can have all of the problems you described and more! I'll bet that your friend made several critical boo-boos.

There are numerous types of underlayment that can go beneath sheet vinyl. Some are approved while others are not. These products must be completely clean and free of any ink, factory stamps, paints, etc. before they are covered with the vinyl. Sheet vinyl manufacturers publish what underlayments can be used with their products. You must check the list because not all approved underlayments can be used with each sheet vinyl!

The spongy areas of your floor might be traced to sub-standard or unapproved underlayment. I have seen many lumber yards sell overlay grade lauan plywood for sheet vinyl underlayment. The only lauan plywood that is accepted by most sheet vinyl manufacturers is Type 1 - Exterior Grade. A better underlayment would be poplar or birch plywood with a fully sanded face and exterior glue.

Poor quality underlayment can have hollow spots in between the veneer face layers. This might be the cause of the sponginess in your floor. Other poor quality underlayments contain water soluble colored extractive chemicals. These dyes might be causing your deep seated stains.

Sheet vinyl discoloration can sometimes be traced to the use of unapproved adhesives. Chemicals within the glues that hold down the vinyl can leach into the flooring and cause color changes and stains. Old adhesives left on existing floors can also react with new adhesives and create stains. The sheet vinyl written instructions tell you what adhesives should be used and what old adhesives require complete or partial removal. Poor quality floor mats, heat from floor registers, radiators and direct sunlight can also discolor new sheet vinyl flooring.

The seam failure you are beginning to experience can be traced to numerous errors. Sheet vinyl products require very specific seam adhesives and sealers. Off the shelf seaming products often are unapproved. The right products can almost always be found at the location where the sheet vinyl is purchased.

To keep a new sheet vinyl floor looking good, you must keep grit and dirt off the floor. These particles react with foot traffic to make human sandpaper. Regular vacuuming or dust mopping must become part of your housekeeping schedule. Wet mopping will also do a great job of removing grit if you frequently change the rinse water.

Companion Articles: Common Sheet Vinyl Problems, Sheet Vinyl Defects

Column 260