Stainless Steel Nails, Screws & Fasteners

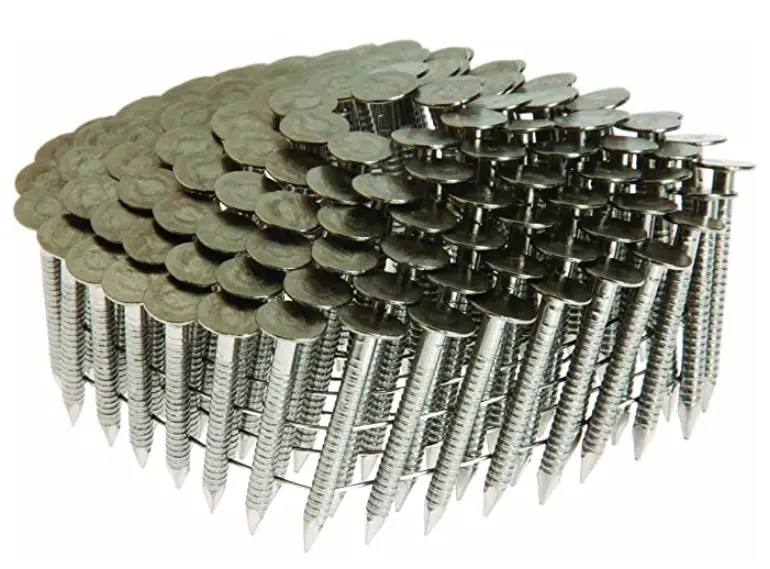

Stainless Steel Nails | These are stainless steel roofing nails. You MUST use these if you live within 20 miles of the sea. CLICK or TAP HERE or the photo if you want to purchase stainless steel nails.

Stainless Steel Nails - The Best You Can Get

Rust is a constant nemesis of many houses. The prolific use of iron and steel in residential home construction is the root of the problem. Iron nails and steel construction components are used for several reasons. Number one, steel is very inexpensive. Number two, steel is very strong. However, iron and steel have a tendency to react unfavorably with water and air. The end result is that orange-brown crust called rust.

Is Rust a Serious Problem?

Rust corrosion can become a serious problem. At first, it simply is a cosmetic problem. Rust stains that appear through paint or run down brickwork are the most common ones. You may have rust stains on your exterior concrete surfaces. However, if left unchecked, steel or iron components can corrode to a point where they lose their structural integrity.

Can Rusty Nails Cause Decks to Collapse?

Yes, inferior nails with a thin coating of zinc begin to rust and corrode on decks. The problem is made worse because of the copper in treated lumber. The copper accelerates the corrosion. CLICK or TAP HERE to read all about the dangers of a deck collapse.

Where Else Can Rust Be a Problem?

The possibilities are endless in many homes. For example, steel reinforcing in concrete can and does rust and corrode. The corrosion actually causes the steel to expand which causes the concrete to crack.

Believe it or not this is all that's left of a steel reinforcing rod. It was encased in concrete just 100 feet from the Atlantic Ocean in Old San Juan, Puerto Rico.

Steel lintels which support brickwork and stonework above windows and doors can readily rust if not adequately protected. Nails, screws, bolts, etc. used in outdoor projects will readily corrode and lose strength. This loss of strength can actually be accelerated if steel or iron products come in contact with chemically treated lumber. The solution is to use a fastener that will not corrode. This is where stainless steel comes into the picture.

Stainless Steel -The Ultimate Metal

Use stainless steel if you never want to worry about rust and corrosion.

Are There Different Types of Stainless Steel?

There are different types of stainless steel, but the most common types are known as #304 and #316.

How Do You Make Stainless Steel?

Stainless steel is an alloy of steel, chromium, and nickel. These basic ingredients are forged together to form a different metal that has greater strength than steel, and excellent corrosion resistance.

Certain harsh chemicals and salt spray can corrode 304 stainless steel. 304 stainless steel has 18 percent chromium content and 8 percent nickel content. As such it is often referred to as 18-8 stainless. 316 stainless steel is the ultimate corrosion resistant alloy. By adding an additional ingredient - molybdenum - to the other ingredients, this form of stainless steel will resist attacks by just about anything you can throw at it.

Stainless Steel Nails | The long smooth silver-colored nail that has no chunks of zinc on it is what a stainless-steel nail would look like. All the nails above have been galvanized. The one being held was electro-plated and it’s rusting after just 12 years. Next to it is a new electro-plated nail. The four gray ones are hot-dipped nails, some have a distinctive irregular coating of pure zinc. The irregular ingots are solid zinc. CLICK or TAP HERE to discover all the facts about galvanized nails. Photo Credit: Tim Carter

What Type of Fasteners are Made Using Stainless Steel?

Stainless steel is used to make siding nails, screws, nuts, bolts, etc. In fact, if you know a good welder, you can fashion brackets, joist hangers, etc. from pieces of stainless steel. Not too long ago, I made a double joist hanger for an exterior deck from stainless steel.

These are just a few of the stainless steel screws you can get. There are countless ones of all types. CLICK or TAP HERE or the PHOTO to discover the exact STAINLESS STEEL SCREW, NAIL, or BOLT you need!

The deck structure was made from redwood and I simply did not want to take a chance with rust making an appearance in several years. Yes, you will pay slightly more for stainless steel hardware, but it will be worth it. You will not have to worry about rust or structural failure caused by rust and corrosion.

Column B363

2 Responses to Stainless Steel Nails, Screws & Fasteners