Build Under A Tent

Build Under a Tent | These odd plastic triangles allow workmen to lay concrete blocks in cold and rainy New Hampshire weather to keep a job moving forward. Copyright 2021 Tim Carter

Build Under a Tent - Old Circus Trick Revived

You’ve undoubtedly heard the phrase time is money. If ever there’s a time when it’s true, it’s now. The talons of inflation are digging into your wallet, purse, and budget with respect to any home improvement project. The sooner you get any job done, the less it’s going to cost. Period.

I’m about to share with you in the next few minutes some stories that should inspire you and your contractor should he need suggestions on how to keep working. Don’t allow him to tell you the weather’s going to cause this or that delay. It’s pure poppycock.

My first lesson in what’s possible when it comes to eliminating weather delays on projects stretches back almost half my life! Thirty-three years ago, I subscribed to every home building and remodeling magazine I could find. Keep in mind, the Internet as you know it wasn’t even a glint in the eye of the tech industry. I consumed tips and tricks from publications and books like you might pop peanut M&Ms in your mouth.

Fine Homebuilding - Build a House Under a Bubble

One of my favorite magazines is Fine Homebuilding. I started subscribing around issue 23 or so. I’d read each issue cover to cover and fortunately, I had a photographic memory. I’d store snapshots of the photos in the magazine in my tiny gray cells that I’d use to help me do things each day on my job sites.

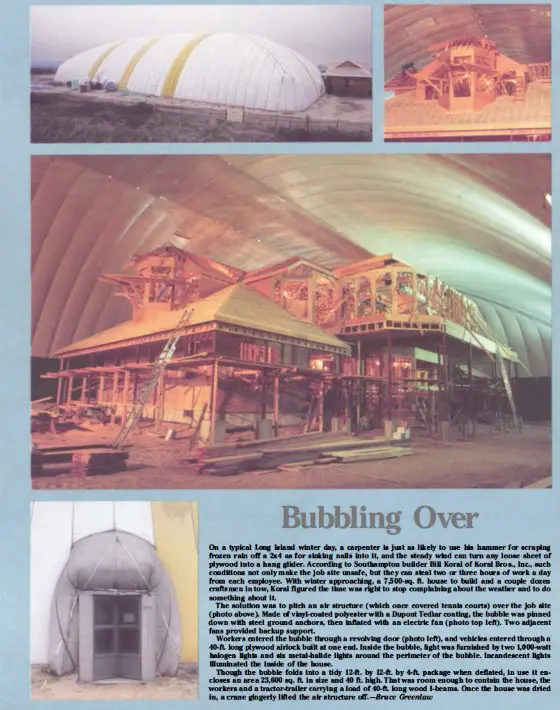

I’ll never forget when I turned over to the rear cover of Issue 51 of the magazine. There were four photographs showing how a new house was being built on Long Island in the Hamptons in the middle of winter under a giant inflatable structure. Mind you, this was 1988!

Fine Homebuilding Issue 51 Rear Cover - Copyright 2021 Taunton Press - Reproduced here under the Fair Use Doctrine guidelines. CLICK or TAP HERE to get a subscription to this fantastic magazine.

Can you imagine that? The builder, Bill Koral of Koral Brothers, Inc., was no fool. He knew that at least 30 percent of each day’s worth of productivity for each craftsman could be gobbled up dealing with Mother Nature. It was to his benefit, and that of the owner, to get the house built as fast as possible. Fortunately, the builder had access to an inflatable structure that used to cover a tennis court. It was a win win-win all the way around. The house stayed dry during construction, the workers weren’t miserable and were safer, and the owner got a much better-built house. I share this to show you it’s possible to do what seems impossible!

Paint in the Rain - A Simple Lean-To

Twelve years ago, a special painting crew was sent to my house to satisfy a warranty claim on my windows. They had to do extensive work to remove the window sashes and then paint parts of the remaining frames with a very special automotive fade-resistant paint.

The three painters had a huge trailer that was a traveling workshop with all the special spray-painting equipment. It was also filled with every imaginable tool they might need for any situation. One day rain was in the forecast. The painters, in a matter of minutes, fabricated a moveable lean-to out of a sheet of heavy translucent plastic and lumber that was in the trailer.

They constructed the lean-to so it tucked up perfectly under the roof overhang and extended far to the left and right of their work area so no rain would get inside my house nor get the window frames wet they needed to paint. It took them less than 30 minutes to construct the lean-to. Clever indeed and it allowed them to get the job done a day early.

Build a Shed in Rainy Northwest

Two months ago, a Seattle entrepreneur scheduled two phone consult calls with me. He was about to start building a wood foundation for a stunning cedar shed kit he purchased online. It just so happens this time of year, the fall can be very wet in the Northwest.

He asked me how he could keep the project moving and not allow the days and days of rain to put the project behind nor get the cedar wet. I shared how he could build a very simple pup-tent design using a giant fiberglass tarp, some rope, and a few 4x4 posts. He built an inverted-V shelter in less than two hours that was both wind and rainproof. He sent me photos of the finished shed under the tarp. It brought a smile to my face, to say the least.

Lay Block in New Hampshire Winters

Lastly, I live in a rural part of New Hampshire, and there’s no free trash pickup. You take your own trash to the town dump and recycling center. For the past few months, foundation work has been going on for a giant new garage and service center for the town public works trucks.

Two weeks ago, I saw workmen starting to build an ingenious triangle-shaped structure around the poured foundation. (See photo above.) It was done to create a warm environment for laying concrete blocks. The project is months behind schedule because of a pier-drilling mistake so not a day can be lost to the weather.

This professional mason is protected from the elements and WARM inside the plastic triangle tent. Ingenious! Think how you can replicate something similar so your job can continue on NO MATTER what Mother Nature throws at you.

The laborers did a fantastic job building this simple structure from sheets of reinforced plastic and some 2x4s. It turned out to be windproof and the concrete block thought it was being laid in June it was so balmy under the plastic with the heaters on.

Should you decide to build shelters as I just described, keep in mind the wind. You must be sure your structure doesn’t blow over or get ripped to shreds. Always use reinforced plastic sheeting. There are plenty of online videos out there that give you tips on how to prevent this. Good luck and get ‘er done!

Column 1432