How to Prevent Cost Overruns

Prevent Cost Overruns - This new concrete sidewalk cracked within months. The homeowner was distraught. There are things he could have done to prevent or minimize the crack. Copyright 2023 Tim Carter

How to Prevent Cost Overruns on Your Projects

You have a county coroner who performs autopsies on some who have been sent back to Heaven. I do autopsies too each week. Many of them. You may have been one of the many homeowners who have reached out to me asking for me to throw you a life preserver as you splash and flail about in the waters of misery. Your repair or remodeling job has gone off the rails. Or perhaps your new-home project is sinking faster than the Lusitania.

To help prevent you from losing vast sums of money, I’m going to share a few recent tales as well as my autopsy results. Often there’s a common thread. It’s my hope you’ll soon see that you need to hold back the trust you place in contractors. Let’s get started.

Several days ago Michael reached out to me. Months ago he invested many thousands of dollars in a new concrete sidewalk, driveway, and front porch at his home. Not too long after the work was completed, he noticed a large crack in the sidewalk leading to his porch. The crack was getting wider by the week.

He asked me, “…is this normal cracking for new concrete and should I accept a patch or should another repair method be used?” I responded that it’s normal for concrete to crack. I pointed him to a past column of mine that explains in great detail the dynamics of concrete. You can read this column on my www.AsktheBuilder.com website.

In a nutshell, concrete cracks because tension forces build up within a slab as it cures. On average you can expect concrete to shrink 1/16th of an inch for every ten feet of slab length. Cracks happen for lots of other reasons too. Expert concrete masons install control joints in slabs to try to encourage the crack to happen where it can be disguised rather than a random irregular crack across the slab.

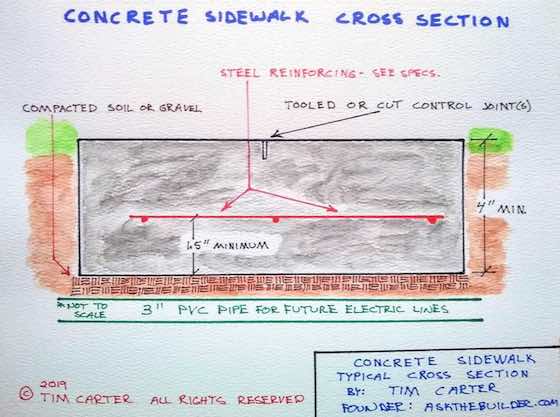

I shared with Michael that had he purchased a small guide I created a few years ago the crack might not have appeared. In the guide, I share an illustration showing how inexpensive reinforcing steel could have been used to minimize the crack ensuring it never grows beyond a hairline crack.

This is a watercolor illustration I made showing how to install concrete. CLICK IT to get all the tips. Opens in a new window.

I garnered from Michael’s tale of woe that he had placed far too much trust in the contractor. He assumed the contractor would do everything right to ensure the concrete would look great for decades. Misplaced trust often leads to disappointment. Michael should have invested a few hours time to discover how to prevent concrete cracks.

Days before I heard from Michael, I was talking on the phone with a woman who’s hired me as her virtual general contractor to rebuild a house from the foundation up. You can do the same as I take on a few clients like this each year.

She’s in the midst of a massive remodel of a home in Maine. A flaw in the house’s block foundation was discovered by a contractor doing demolition work. The project architect never saw it or if she did she didn’t think it was a big deal. I’m not sure if an ASHI home inspector was used when the house was purchased. She/he may have spotted the flaw allowing the woman to negotiate a better price on the house.

The block foundation might have to be removed and a new cast-concrete foundation will go in its place. If this needs to happen, I estimate this will create an immediate painful cost overrun of about $60,000.00. Imagine having to swallow that so early in a huge project. It’s very possible the flaw would have been identified in a $650 house inspection by one of the top inspectors out there.

It's possible the concrete block foundation might be able to be reinforced with pea-gravel concrete, rebar and/or junior I-beams. This conundrum is being discussed as I write this column.

The day after dealing with the block foundation issue I spoke on the phone with Rita. She’s invested in past consult calls with me about a failed garage foundation. This time is was an issue with her son’s new three-story townhome. The temperature on each level varies by a great deal.

She wanted to know what could be done to try to create more even temperatures throughout the residence. I shared with her that she had a few options that might work. I also shared with her that I didn’t have that issue at all with the heating and cooling in any of the houses I built.

My houses had all the correct-sized ducts leading to each room. Detailed calculations were performed to determine exactly how much hot or cold air needed to be put into each room to keep it at the desired temperature. Each room except kitchens and bathrooms had strategically placed return air ducts.

You can avoid financial and emotional heartache by investing time BEFORE you sign a contract. Never before has it been easier to get up to speed on the right way to do things. Many manufacturers and trade associations have fantastic videos you can watch to get a feel for how products are supposed to be installed.

It’s your job to watch these or read installation instructions ahead of time so you can determine in conversations with bidding contractors if they know how to do the job correctly. You can also hire me to help you get up to speed. The last thing I want to do is perform an autopsy on your failed project. Do your due diligence or suffer the consequences.

Column 1523