Every now and then, I stumble across a very interesting product. It appears that it has happened again. Fiber cement siding products are simply a magnificent alternative to conventional wood siding products - plain and simple.

The thing that is amazing about fiber cement is that it is not a new product. I have actually worked with the material for many years. Here in Cincinnati, you can drive through the older neighborhoods of Fairmont, Clifton, Norwood and Price Hill and find vast quantities of the material. Based upon the style and types of older houses you see it on, it apparently was a very economical material back 90 years ago. The good news is that it is still a very economical building material.

Concrete Roots

Portland cement was discovered in the 1800's. It didn't take long for inventors to find that it had lots of different uses besides a paving material. It made perfect sense to blend the cement paste with fine fibers and create an "armor" plate - like siding. After all, house were constructed with rock for years. Why not nail on thin sheets of rock? I sure wish I had thought of the idea!

Nails Without Splitting!

You would think that thin pieces of fiber cement siding would readily split when you drive a nail through them. It doesn't happen - unless you nail very close to an edge. Wait till you try it. You will be amazed at the ease of installing this water, fire and insect resistant building material.

If you choose to use fiber cement siding, it installs just like regular wood siding. There are a few exceptions - basically, you can blind nail this material very similar to the manner in which vinyl siding is installed.

Installing any siding correctly is becoming a lost art. Ninety nine percent of the installations I see are being done incorrectly. The siding installers seem to think that the siding will make the house/structure waterproof. Nothing could be further from the truth. Seams and butt joints between siding and trim are all excellent locations for wind driven rain to enter. This water will readily begin to rot the sheathing and your structural wood members.

If you ever have the luxury to partially demolish an older home built by old craftsmen you no doubt will run into some tar paper. Tar paper was the only water repellent available for the old timers to use. But guess what? It was very effective. Tar paper was used under old fiber cement siding, traditional wood siding and stucco. You need to use it under your new fiber cement siding at the very least. A better alternative is to use a moisture and air infiltration barrier. These products are easier to apply and offer great energy savings potential. If you choose to use tar paper, remember that you work from the bottom up. Each successive piece must overlap the one below. This is how water is shed to the bottom of the structure. Don't forget that your first piece should extend 1/2 inch over the top of the foundation. This will ensure that water will not roll back under the sill plate and into your basement or into your house should you live on a slab.

Trim First - Siding Last

Installing siding is a multi-step process. The fun part of actually applying the siding is usually the last thing you do! The first thing you must do is apply all of your inside and outside corner boards, window trim, starter strips and flashings. Once all of this detail work is complete, you can finally install the siding. Currently, the major fiber cement siding manufacturers do not have thick fiber cement trim boards available. I'm told this is a future possibility. As such you are forced to use wood trim or vinyl. Either material will do fine. To get long lasting results with wood trim, it is absolutely necessary that you backprime the wood BEFORE installation. Backpriming simply means that you must paint all surfaces, edges and ends of the wood before it is installed. It is actually preferable to paint it with two coats. When final cuts are made, these fresh cut ends need a coat of paint just before the wood is nailed into place.

Caulk & Flashing at Butt Joints

Because siding pieces only overlap one another 1 and 1/4 inch or so, butt joints (where two pieces of siding butt against one another) are highly susceptible to leaking. The manufacturers recommend that you caulk these butt joints. That is a good start. I urge you to cut small pieces of 30 # felt paper to act as a flashing. These strips of paper need to be two inches wide and two inches longer than the width of your siding material. As you nail the end of your first piece, slide a felt strip in place so it is up 1/4 inch from the bottom of the piece you are installing. One inch of the felt should be under the piece you are nailing. The remainder that is exposed will be covered by the abutting piece of siding.

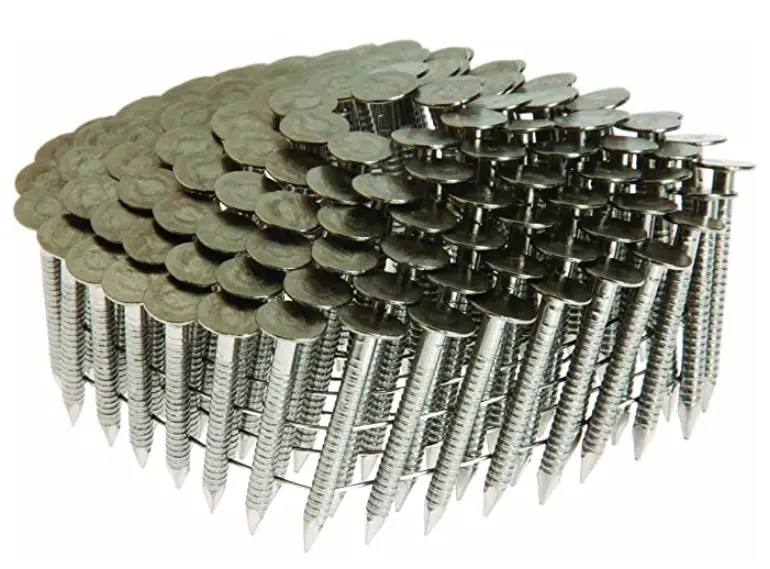

Nails

Spend the extra money and use stainless steel nails. These nails are less prone to bending as you nail. Also, you never have to worry about rust!

Specific Installation Instructions

No matter who installs your fiber cement siding or panels, you MUST obtain and read the installation instructions. Each manufacturer has different ways to install their product. The process of reading the instructions may take only 1/2 hour!

If you hire a contractor to install the siding, make periodic visits to ensure that the job is being done right. Remember, the contractor can't see your house from his!!! Mistakes and leaks will not bother him.........

Column B185