Construction Tips for Unfinished Spaces

Uneven Concrete Floors

Some people with basements have floors that slope steeply for drainage purposes. There are two ways to deal with this: pour a thin concrete overlay (see Bulletin 379 - Concrete Overlays Installation), or build a wood floor over the concrete. The wood floor system can be tough. You need to determine the highest point in the floor system and work backwards from there. I always use a transit to establish this high point and then translate that point to the side walls. I then install CCA treated lumber 2x4s around the perimeter of the room. The wide face of the 2x4 touches the floor. This allows you to stretch mason's string tightly between the members to get a smooth plane out in the rest of the floor. You install the rest of the treated 2x4s with shims beneath them for support. Place the shims at 16 inch centers. I then stretch a high quality vapor barrier (see Bulletin 109 - High Performance Vapor Barriers) on top of the 2x4's before installing the subfloor plywood.

Be sure to provide access to any floor drains! These drains will need to stay functional in case of basement flooding. Also, you will periodically have to pour water in them to prevent sewer gas from building up.

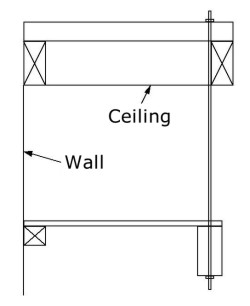

Walls - Build in Place or Tilt Up

The walls for this project can be build in one of several ways. If you choose to build them in place, you install the bottom plate first, then the top plate, then fill in the wall studs. I like to use 2 x4's for the walls. This provides plenty of space for insulation, wiring, full depth electrical boxes, and plumbing pipes. Furring strips limit the amount of insulation you can install. They also limit your ability to easily wire a space.

Don't assume that foundation walls are straight and plumb. They are usually not! Check to see if the walls lean in or out. They can do both on the same wall! I hold my walls away from the masonry walls at least one half inch. I don't like to see untreated lumber touch masonry. This also gives you room to account for crowned studs and masonry wall movement.

If your walls are to be attached directly to concrete floors, this can be done without expensive anchors. Use a hammer drill with a 1/4 inch bit. Drill through the wall plate and into the concrete about 2 inches. Then take two 16d sinker nails and nail them into the hole in the plate at the same time side by side. If you use a 20 oz. hammer and hit them straight, they will go in readily. It is virtually impossible to pull the nails out! Just anchor the bottom plate every 4 to 6 feet.

The top plate position is determined by dropping a plumb bob to the edge of the bottom plate. Transfer the bottom plate location to the joists above or to blocking pieces should the ceiling joists run parallel with the wall. Cut and install the top plate. Fill in the studs at 16 inch centers.

If you decide to build the walls on the floor and tilt them up, make sure they are 3/4 inch less in height than the space they are to fill. If you build them full height they will get stuck as you tilt! Use blocking at the top to fill the gap once in position.

Always try to line up wall studs with floor joists above! This will make it easier to run plumbing pipes and heating ducts.

Mechanical Systems HVAC, Plumbing, Electric

HVAC: This work goes first. Ductwork is cumbersome. Think of plumbing at the same time. Basement spaces usually require minimal heating and cooling unless you space has a walk out wall(s) which is totally exposed to the elements. Remember, locate supply ducts near outside walls. Install return air ducts on interior walls away from the supply ducts. The idea is to 'draw' air across the room.

Plumbing: Now is the time to upgrade plumbing to other parts of the house. It will be messy to do it 2 years from now! PVC drain stacks will be noisy. If these are present in your existing space they will need to be wrapped with insulation to minimize sound transmission. Cold water lines may need to be insulated if you have had problems in the past with condensation. Condensation can drip onto your new ceiling.

Electric: All electric work has to be done per the National Electric Code. If you don't know how to do this, get an electrician who does! People die every week in the USA from electrical related house fires. Calculate loads to make sure you have enough circuits! Remember a 14 gauge wire is only rated for 15 amps or 1,800 watts. A 12 gauge wire can handle 2,400 watts or 20 amps. Think.... if you put in 10 recessed ceiling lights each with a 75 watt bulb, you have already taken up nearly half the capacity of a single 15 amp circuit! Appliances, hot glue guns for hobby rooms, etc. all take their toll on circuitry. Make a list of what you intend to have and calculate the loads from this list.

Insulation / Vapor Barriers

Insulation is a must. If you chose 2x4 walls, you will be able to install batt insulation. You can use unfaced insulation if you installed the vapor barrier already. If not, you may want to use foil faced insulation. The foil facing should be visible from the room side.

Drywall / Paneling / Artificial Stone .......

Wall surfaces are next. Choose the one which will give you the most flexibility. For me it is drywall. It can always be the base for a future material such as paneling or artificial stone.

Ceilings - Think of the Future .......!

If you have ever tried to fish a wire in a basement that had a finish plaster ceiling, I know what type of ceiling you would install! Before you rule out acoustical tile as being "too commercial", you had better go look at some. There is a wide variety of styles, grid, etc. You can also mix and match ceilings. Create a tray or soffit perimeter around the room. Fill the center with acoustical tile. This way you can access a huge area of the ceiling. This will come in handy in the future - trust me on this one.

Flooring - Think Floods .....

My inlaws have a finished basement. It has flooded at least 5 times in the past 10 years. After the second wall to wall carpet was thrown away, they finally switched to area rugs. Vinyl tile has come a long way. Colors and patterns are attractive. Give it a serious look. Beware of hardwood flooring in basements. The Hardwood Associations CAUTION against its use below grade in even historically dry basements. Don't tempt fate. Mother Nature always bats last.

Finishing Materials - Options

Rough Construction Materials

Want perfectly straight walls? If so, steel studs may be your cup of tea. You can insert 6 inch high pieces of 2x4 in them at top and bottom to secure baseboard and crown moldings. This allows you to use nails for your trim instead of screws.

If you are worried about wet floors for some reason, you can buy treated plywood! Most people don't realize this. It is perfect if you are concerned about insect infestation as well.

Thinking about using 2x3 walls for some situations? Well, if doors or plumbing lines are in these walls you may have problems. Remember, standard door jambs are milled thinking that you will use 2x4s with 1/2 inch drywall on each side.

Are you worried about sound? If so, think cast iron for plumbing drainage stacks. Vent pipes can be PVC. Seal all holes and void spaces that go to other rooms or floors. These are conduits for noise transmission. If you decide to drywall the entire ceiling in your new room, you can install a fiberboard first and then the drywall. This will do a decent job of soundproofing.

Electrical and Communications Wiring

Now is the time to think ahead for the future. Not only should you think of this new space, but other rooms in your house as well. Does this new space cut off the rest of the house from the main electrical panel or telephone or cable TV termination points? If so, add wiring now to other points within the house or attic for future use. Or, at the very least, install several conduits through which wires can be added at a later date.

Never install telephone or cable TV wires in the same holes or in line with 120 volt electric lines. Power going through the high voltage lines can sometimes create an interference in the low voltage lines. Always run low voltage wiring AFTER high voltage wiring. The high voltage wire can withstand more abuse than low voltage wiring. Don't forget about security or alarm system wiring. Drill separate holes!

Fire Sprinklers - Sounds Crazy but ...

Now is the time to install a fire sprinkler head or two in the new room. There are fancy pop down heads that fit flush with the ceiling until activated by rising temperatures.

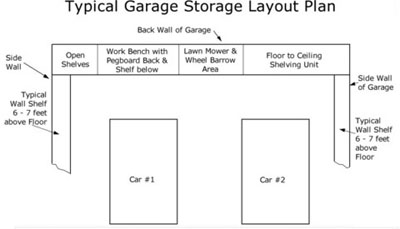

Hobby or Craft Work Stations

Do you have room to create a hobby or craft space? If so, the wall outlets should be 42 inches off the floor. Create a space to sit at the counter top with a bar stool by leaving out a cabinet or two along the wall. I plan to do that in my basement remodel. Use standard stock wall cabinets above the countertop to store supplies.

Unique Wall Finish

Want to create a unique look? How about finishing off one wall with artificial stone? You can do an entire room and create a medieval castle hall! Let your imagination run wild. If the room is to be for children, why not install fiberboard covered with fabric? It can be a giant bulletin board using colored push pins. Use this same wall treatment if you have a dartboard planned.

Create walls that are art galleries for your children's school pictures and projects. This will add color to the space. The walls will change monthly as more drawings are brought home.

Column B152