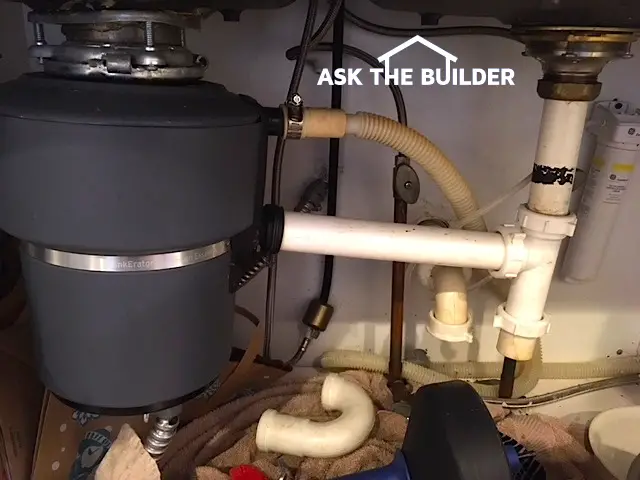

When you move into a new home, the last thing you might be expecting are problems of any type. After all, you did buy or build a new home. But problems do raise their ugly heads over time and some of the most troublesome seem to be plumbing hassles. Your builder and plumber can do a few things now that will minimize just about every imaginable plumbing problem.

PVC or Cast Iron Piping?

Let's first talk about drain lines. The material used by many builders and plumbers today is polyvinyl chloride (PVC) plastic piping. It is easy to work with, has a smooth interior surface that virtually eliminates clogs, but it is not a dense material. As such it can be noisy. Flush a second floor toilet and those on the first floor can often hear the water rushing down a wall or across a ceiling. If you request new easy-to-install cast iron drain lines that handle water, noise will not be a problem in the future.

PVC piping also expands dramatically as the temperature of the pipe increases. Drain water from a sink or tub and you might hear all sorts of snaps, pops and crackles in your walls as the pipes heat and expand and as they subsequently cool and contract. The noise comes from the piping rubbing up against wood framing members. Careful installation can minimize these contact points, but using cast iron piping eliminates the problem altogether.

For some reason access panels behind tubs and showers have seemed to suffer the same fate as the mythical city of Atlantis. You rarely find these useful things in new homes. An access panel allows a plumber to gain quick access to all of the plumbing, both drainage and water supply lines, to almost all tubs and showers. Intelligent planning will hide these panels inside an adjacent bedroom or linen closet. These panels can save you hundreds of dollars in repair bills should a faucet have to be replaced in the future.

When should you buy replace faucet cartridges?

Be sure to buy replacement faucet cartridges for each faucet as soon as you move in. I prefer to place these in a ziplock plastic bag that is attached to the inside of all sink cabinets. Place them up and out of the way, but know that when and if a faucet starts to drip, you have the needed part on hand and ready to install. These parts are inexpensive and will rarely go bad when stored in their original packing material.

Does your water heater need an expansion tank?

Water heaters are often overlooked. Your local plumbing code may force the plumber to install an expansion tank with your water heater. These devices absorb the extra pressure and volume of water that occurs when cold water is heated. These tanks can extend the life of a water heater.

Ask your builder or plumber to install a secondary anode rod in the cold water inlet. This relatively inexpensive anode rod can frequently double the life of the water heater. It is indeed a wise investment.

Ball Valves or Stem Valves?

Be sure each and every shut off valve in the house is a ball valve. These valves offer the least trouble over time and when they are needed they usually work. Traditional stem valves can be difficult or impossible to turn years down the road because of sediment buildup in the valve body. Ball valves rarely are harmed by sediment and furthermore their internal design allows full unimpeded flow of water through the valve.

Carefully plan the location of exterior hose bibs. All too often newer frost-proof hoses are installed low to the ground as they pass through the floor cavity to the outside wall. These hose bibs can be placed higher up on exterior walls if they are piped through an interior wall that intersects with an exterior wall. I would also have your plumber install an accessible ball valve on the branch water line that feeds each hose bib. In case of a future leak or problem, you can quickly shut down the water at this hose bib.

If your main water line enters the basement through a foundation wall, be sure the plumber install an inexpensive boiler drain just past the house shut-off valve. This boiler drain is equipped with standard garden hose threads. By attaching a hose to the drain and extending the other end of the hose to a floor drain, you can quickly drain the entire water supply lines in the hose allowing you to work on them with ease. This simple boiler drain may come in very handy if a future extended power outage during the winter forces you to quickly drain all water to prevent burst pipes.

Column NH042