DEAR TIM: Every time I visit my local home improvement center, I seem to see another new exciting electronic tool. Just what tools are you aware of? Are these tools safe in the hands of a homeowner, or should they only be used by professionals? Also, are the manufacturers' claims of accuracy, dependability, etc. factual? What is your personal experience with some of these tools? E. R.

DEAR E. R.: I share your excitement with respect to electronic tools. The industry has experienced fantastic growth during the past few years. Not only have sales gone through the roof, but new products seem to be introduced to the marketplace on a monthly basis. I only wish that some of these tools had been available years ago. There is no doubt that all of these tools would have saved me vast sums of time and money on my building and remodeling jobs!

Currently, I am aware of a wide variety of electronic tools. Electronic building calculators, electronic levels, ultrasonic measurement devices, laser levels, and ultrasonic sensing devices are currently on the market. I have been told that a new ultra wide band radar tool capable of "seeing" through concrete is ready to be released as well.

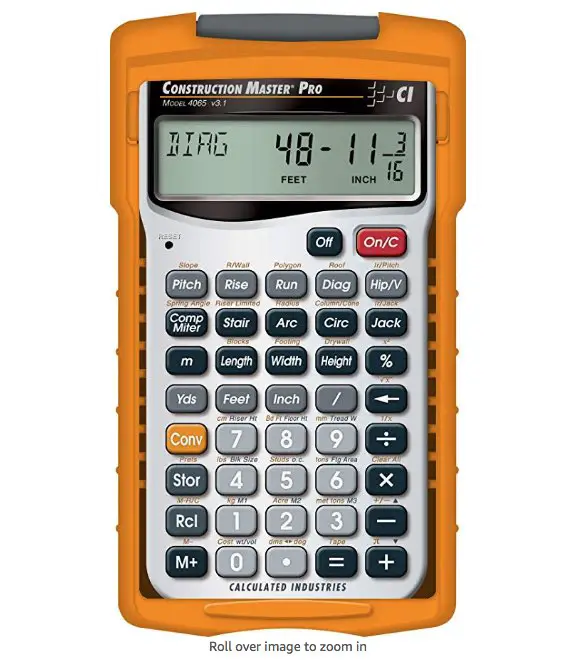

This is the type of calculator you should own if you're going to build a new home. It allows you to CHECK to make sure things are SQUARE!!!

The electronic calculators are very interesting. They have many unique features such as the ability to add and subtract fractions, conversion to any dimensional format, including metric, automatic solutions for roof framing, instant solutions for circle area and circumference, and much more. If you like to work with electricity, you can even purchase a specific calculator which solves many common electrical problems.

The new electronic levels, I think, are very exciting. These items operate on a nine-volt battery for up to 500 hours. They are extremely accurate. Some models even let you control the degree of accuracy. Several of these levels allow you to choose the mode in which to work. The display will indicate a simulated bubble, degrees, percent either slope, or pitch. Some levels feature a hold button which can freeze a reading on the display, in case the level is in a hard to read location. You can also purchase an electronic water level which can be used by one person. This level allows you to create level marks around corners and across rooms by simply listening for a tone.

The ultrasonic measurement devices are fantastic tools if you hate fiddling with a steel or wood tape measure. What's more, several of these can measure, using a narrow ultrasonic beam, up to 60 feet with 99.5% accuracy. Some models are equipped with an aiming light which allows you to aim the device directly at what you are measuring. These devices are also calculators which can measure instantly the area and volume of a room. Virtually every device offers format conversion.

The laser levels I have seen are wonderful. In the old days, it required two persons to operate an optical level or builder's transit. Laser levels require only one person. You simply set the level up, turn it on, and watch for the rotating red beam of light. The light beam strikes whatever surface you are working on, or if out in the open, it strikes a reflective target pole which you adjust up or down. These levels are very handy.

Soon to be released is a new radar tool. This tool will enable you to see right through concrete or walls. The results will be displayed on a screen. You will be able to clearly see pipes, wires, studs, etc. The current sensing devices are useful for finding studs, however, this new device represents a giant step forward.

I personally feel that you or any homeowner can operate these tools and obtain professional results. I have used many of the tools and have never been disappointed. These tools will serve you well for many years, however, you must handle them with care. The accuracy of the tools depends upon their often sensitive, electronic components.