DEAR TIM: The bugs are driving me crazy in my back yard. It is time for a screened enclosure. Is it possible to build an economical screened enclosure using readily available materials? What are your feelings concerning aluminum enclosures as opposed to wood? Do you think this is a project for an accomplished DIY'er? Do you have any tricks of the trade you will share? R.C.

DEAR R.C.: Every screened porch that I have built has relieved the bug agony you are now experiencing. This is a project, I believe, that can be successfully tackled by a serious DIY'er. You will need to have well thought out plans, proper zoning clearance, a building permit, and approximately 160 man/woman hours of time.

Think before you do anything. How many people will enjoy breezy mornings and evenings within this enclosure? Are you going to have a table and chairs? Use your existing living room or dining room as a possible template for sizing this new structure. To be on the safe side, set existing furniture out in your yard where the structure will be. Create a square or rectangular shape, measure, and start to draw!

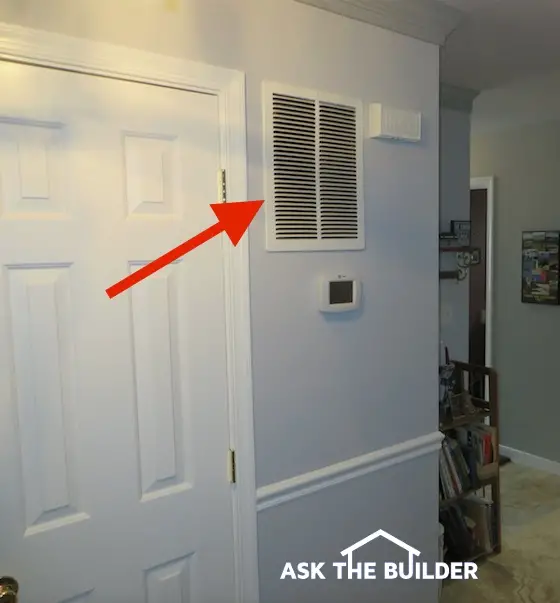

After you have obtained permission from your governmental officials, it is time to build. Wooden screened porches often allow you to match the architectural details of older homes. This feature comes, however, with a price tag - sustained, periodic maintenance. Aluminum screened enclosures offer rapid erection capabilities, low maintenance, and numerous design possibilities. Aluminum structures, however, usually require professional installation services.

Building a screened enclosure is possible on a tight budget. There are several tricks you can use to accomplish this goal. Consider building the porch on top of a ground hugging wood deck instead of a concrete slab. Utilize ready made full panel screen doors for your walls. These doors can be installed side by side in between the support posts of the structure.

Use construction grade redwood for your support posts. This grade of lumber will give you many years of service if you prime and paint each post, including the top and bottom, before installation.

Construct a simple gable or hip roof for your porch. The rafters and roof sheathing will be visible from the inside of the porch. However, if you paint the underside of the roof a medium gray, it will look very acceptable. The angles created when building a hip roof will make for interesting conversation when your friends are sipping iced tea. Accept the challenge and try to construct this roof system.

There are several things you can do to minimize maintenance and maximize comfort. Prime and paint (stain) all wood BEFORE it is assembled. If you build the porch and then paint, numerous wood surfaces will be bare. Rain water will eventually locate this wood and cause paint failure and eventually rot. Be sure to plan ahead for the installation of electric outlets, overhead lights, and a paddle fan. Install these electric devices in accordance with the National Electric Code. Screened porches can become wet creating an increased shock hazard.

Creating a porch of your dreams requires an understanding of the elements, both in construction and climate. Better Homes and Gardens Porches and Sunrooms is a wonderful book to help you decide and plan a porch or sunroom that is right for you. In this book you will find chapter by chapter, evaluating and exploring you options, creating elements of style - porches and /or sunrooms, planning, and the basics of building. There is even a chapter on building taking you through the process point by point, including tips for choosing and working with building professionals.

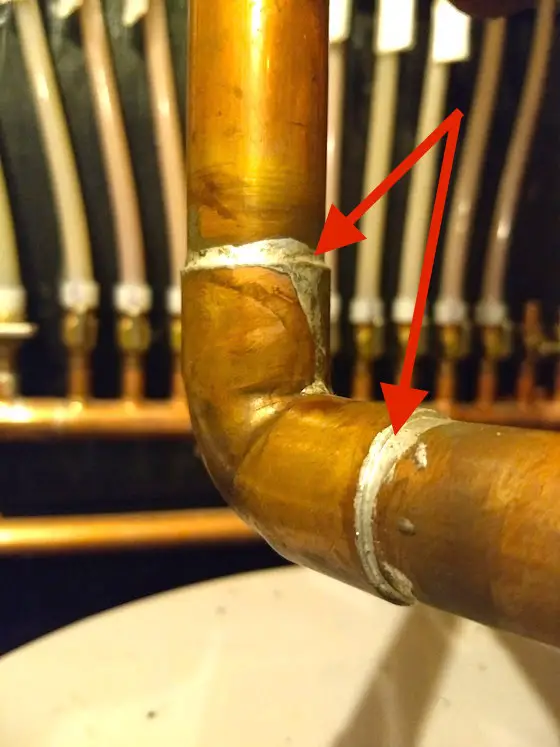

Open the flux container. You will see a gelatin like substance that usually contains zinc chloride, ammonium chloride, and paraffin. Stir the flux well to mix it, especially if it has been sitting in a hot area. Use a small flux brush to apply a coating to the areas of both the pipe and fitting you have cleaned. Don't get the flux in your eyes or mouth!

Open the flux container. You will see a gelatin like substance that usually contains zinc chloride, ammonium chloride, and paraffin. Stir the flux well to mix it, especially if it has been sitting in a hot area. Use a small flux brush to apply a coating to the areas of both the pipe and fitting you have cleaned. Don't get the flux in your eyes or mouth!