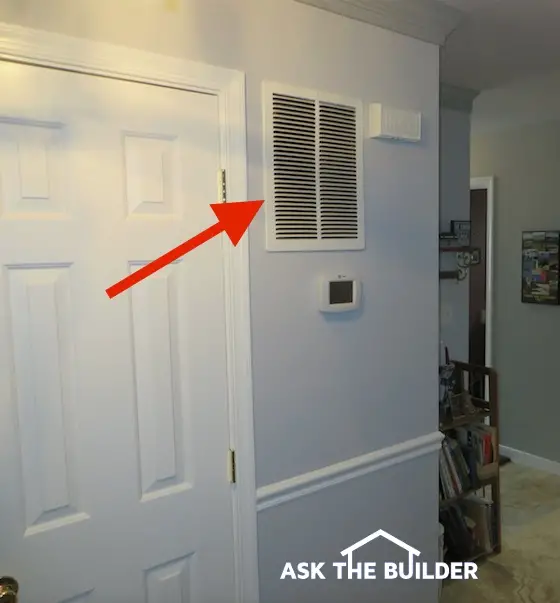

Return Air Problems | The red arrow points to a large wall-mounted HVAC return-air vent. The furnace or air handler is probably on the other side of the wall behind that door. Copyright 2018 Tim Carter

Return Air Problem - Air Conditioning Blues

DEAR TIM: We just had central air conditioning installed in our two story house. The air conditioner seems to work fine, however the second floor rooms are warmer than the first floor rooms. It gets very hot upstairs in the late afternoon. What might be the problem? The contractor says this happens all the time. What, if anything, can be done to correct the problem? Where do we start? F. R.

DEAR F.R.: So, it happens all the time ... Maybe on his jobs it does, but not on mine. Your central air conditioner may have been installed by a contractor who doesn't realize that hot air rises and cool air falls.Successfully installed central air conditioning can easily cool two story houses.

How Do You Check Ductwork?

Before we do anything else, let's make sure that the cold air from the air conditioner can get to each room. Check to make sure that the supply duct register in each room is fully open. Do not allow furniture to cover or block these air outlets. Check the ductwork piping in the basement or furnace room for damper controls on the individual supply pipes that go to each room. These controls are little levers that attach to a metal disk inside each pipe. They enable the contractor to balance or adjust the amount of air going to each room. Be sure these are fully open on the pipes leading to the second floor rooms.

For you to properly cool interior spaces, you must replace the hot air in each room with a sufficient amount of cool air. The amount of air required depends upon the size of the room, how many windows it might have, the number of exterior facing walls, the amount of ceiling and wall insulation, etc. The cool air enters each room through supply ducts. These can be located in the floor on outside walls beneath or very close to windows. In some instances, the ducts may be located in the ceiling.

CLICK or TAP HERE to get FREE BIDS from Local HVAC Contractors

How Do You Replace Hot Air?

Because hot air rises, it needs to be "vacuumed" off the ceilings in the second floor of your house. My heating contractor always accomplished this task by installing a return air ducting system which funneled the hot air from the rooms back to the furnace/air conditioner air handler.

Where Do You Install Return Air Ducts?

Return ducts should be located in each room very near the ceiling on an interior wall. This return air opening pulls hot air from the top of the room. The heavier cold air which is flowing from the supply duct is pulled across the room and up towards the return duct. On its way to the return duct, the conditioned air cools you and the rest of the objects in the room. These same principles must be used to cool single story houses as well.

What If Your House Does Not Have Return Air Ducts?

If your house does not have this return air ducting on the second floor, it frequently can be added. The challenge is to install adequately sized ductwork from the second floor hallway to the basement or furnace room. The hot air from the second floor rooms can be collected in the hallway and sent back to the air conditioner. Rectangular holes can be cut into the wall space just above each bedroom door. Each side of the hole can be covered with a standard return air grill. These holes allow the hot air from each bedroom to easily enter the hallway.

Once this hot air has a pathway into the central hallway, an experienced heating and air conditioning contractor can convert one or two stud wall cavities into the initial return air duct. At the floor level, this stud cavity is then connected to a traditional metal duct that is connected back to the return air ducting system. Sometimes this duct can be hidden in the corner of a first floor room or fitted into a first-floor closet.

The lever you see on the side of the round metal duct is a damper control. It is connected to a round metal disk inside the duct pipe. If I rotated the lever so that it was straight up and down, the disk would block 90 percent of the air flow in the duct.

Without this second floor return air system, the heavy cool air being discharged from the supply ducts in each room can't do its job. It often floats along in a layer near the floor. It eventually cascades down the stairwell to the first floor. This is one reason why your first floor is so much cooler than the second floor.

Author's Notes

December - 1998

I just received an email from Edna R. who lives in Oregon. Edna read this column and had an interesting story to share about another cause of poor circulation. I'll let Edna tell it in her own words.

"......We visited at a 3-year-old rental home several years ago. The hosts were living in the kitchen and family room because the bedrooms at the far end from the furnace were too cold and the living room half way to the bedrooms was not warm enough to sit around in.

When I suggested they check out the furnace filter, they weren't even sure where it was. Apparently the previous renters didn't know either! The lint and dust were jammed into the allotted space and came rolling out in packed balls when the filter was removed.

Many people raised with electric heaters and fireplaces are often unaware there are filters on their forced air furnaces. They need to be told OFTEN to check filters and where they are in the heating system. Thanks for listening to me."

Column 143