Settlement Cracks

DEAR TIM: I am beginning to notice cracks in the foundation, concrete slabs, and some of the interior walls and ceilings of my home. I am concerned that the house may be settling. Do all houses settle? What can cause this to happen? What can one do to minimize cracking in a home? Who is the best person to call for advice? Mandy S., Sulphur Springs, TX

DEAR MANDY: The word settlement, in my opinion, is one of the most misused words in the residential construction industry. There is no doubt that your house may be experiencing settlement. In addition, it may be suffering from upheaval, frost heave, slippage, lumber and concrete shrinkage, and compression stress caused by insect damage! Wow, I sure know how to ruin someone's day, don't I?

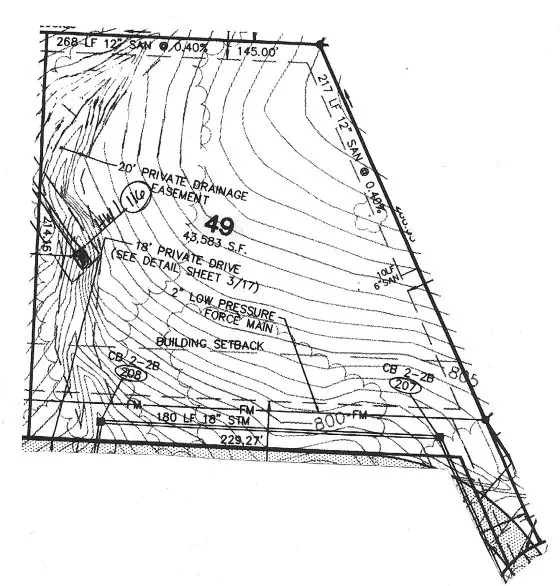

Settlement happens when parts of a house drop below the elevation or height where they were placed during the original construction. There are numerous reasons why this may happen. The soil beneath the foundation or beneath column supports may shrink due to moisture loss. The soil may not have been compacted properly before the foundation was installed. Large pieces of organic material may have been included in the soil under the house. When it decays, the soil above it collapses to fill the void. The list of possibilities is nearly endless. Not all houses settle, but many suffer cracking of one type or another.

My own home has hairline cracks in the foundation as well as numerous cracks in the basement floor. The cracks are normal concrete shrinkage cracks. Concrete shrinks as it dries and cures. It is not uncommon to see 1/16th inch of shrinkage for every 10 feet of concrete length. This shrinkage tends to pull or tear the concrete apart. Sharp 90 degree corners at windows, doors, and offsets in slabs and foundations are excellent locations for the cracks to begin.

If you get up on my roof and look at my chimney flashings, you would think my house has settled nearly an inch and a half. This relative movement could have been a combination of upheaval of the chimney and settlement of the house, but I am inclined to think it is due entirely to lumber shrinkage. Even kiln dried lumber will shrink as it acclimates with the atmosphere and dry conditions inside a home. A multi-story home, like mine, can easily see 3/4 inch or more shrinkage depending upon the moisture content of the wood when the house was built and the species of lumber that was used.

Some soils are very sensitive to moisture gain or loss. Certain clay soils can expand nearly 20 times their volume if they get saturated with water. If this happens because an under-slab plumbing pipe fails, a large hump can develop in an interior slab. Other expansive clay soils can shrink and take a structure with them as they dry out. If you build in areas that have these types of soils, you need to keep soil moisture as constant as possible. One way to accomplish this is to install perforated drain pipe around the foundation. As part of the piping layout , install a tee fitting and a riser pipe up to the surface. If a drought sets in, use a garden hose to inject water into the piping system. This will trick the soil around the foundation into thinking it is raining at the surface.

Structural cracking in houses can be minimized if you take precautions. If you are building on fill dirt, make sure it is properly compacted. Geotechnical and soils engineers can perform soil tests to make sure the soil can support the building. If you live in a cold climate, make sure that all footings are installed below the depth that frost normally penetrates the soil. Foundation walls need horizontal steel bars near the bottom and at the top of the wall to offset stress forces. A residential structural engineer can design steel reinforcing rod placements to help hold footings, foundations and slabs together.

To minimize lumber shrinkage, try to get your house under roof as soon as possible. If the lumber does get saturated by rain during the construction process, try to get it to dry out by keeping windows and doors open as construction continues. Consider installing fans to accelerate evaporation. If you can get the framing lumber to shrink before the drywall, finished flooring, cabinets and trim are installed, you will see minimal cracks.

Column 288