The following comments are from homeowners who emailed me. They both speak volumes about some of these coating products:

"I was just wondering if you know of anything a consumer can do if they fall prey to having this siding put on their house? We had a beautiful cedar home that we wanted to have 'maintenance free' and save on our fuel costs, so we had it installed. As your May, 2002 article shows, it did absolutely NOTHING. We have been going around and around with them for a year and a half. I even got the Better Business Bureau involved, but there is only so much they can do. The company that we actually used to apply the siding is now NO longer selling it. So, it's apparent to me that it isn't working, they are aware of it, and I want my money back. I would appreciate it if you have any insight. Thanks," Kim M., Concord, NC, October 24, 2002

"Thank you for the article about liquid stucco. I almost fell into this trap and paid $9600 for nothing. It sounded way to good to be true and the guy even showed me the space shuttle picture and the same photo is on his brochure. I wonder if he can get in trouble for that? They also claim to have painted all the big light houses of the North and the Lincoln tunnel. Do you think that is true? I'm sure glad I didn't give him the deposit. He said if I give a deposit today that he will lower the price $1000. That made me think! Thanks again," Jimmy, June 14, 2004

Please read additional emails at the bottom of this page. They are from other consumers and people who own liquid-spray-on coating franchises.

DEAR TIM: Several companies are advertising liquid siding and liquid stucco coating that can be sprayed on my home. The companies claim enormous energy savings and that the product will never peel, blister or chip. Are these claims realistic? This product seems too good to be true. Darryl McC., Louisville, Ky.

DEAR DARRYL: Over the past few months, you and many other readers have sent me letters and e-mails concerning these exterior coating products. Fortunately, you and the others are smart enough to hesitate and ask. I am fearful that many other consumers have possibly trusted the ads or sales pitches and have become victims.

Numerous companies, I have discovered, are advertising and selling these products. All the products seem to involve a two-or three-coat system applied by spray equipment, and many are offered in hundreds of colors. The ads and sales brochures say that the materials can be applied over wood, brick, stucco, aluminum siding, concrete block, vinyl, etc.

Miracle Liquid Siding Ads

The ads sure make these products sound great, but the buyer better beware. Let's start with many of the ads' claims that these exterior coating products can save you money on heating-- a claim that in the case of one liquid siding company has received a stern rebuke from the Federal Trade Commission.

I, like the FTC, am deeply troubled by the super-insulating claims. Some companies even say their thin coatings contain ceramic microspheres that provide insulating properties similar to the heat shield tiles on the Space Shuttle. Whatever the intergalactic claims, though, it is highly doubtful you will see a noticeable savings in your energy bill should you coat your home with these products.

Heat loss and heat gain through the painted surfaces of a home account for a minority of energy consumption. Air infiltration and energy loss through windows and doors, attic spaces, slabs, basement walls and floors account for the lion's share of your energy bills. These products do nothing to stop the flow of energy at these locations.

On April 3, the FTC issued a report dealing with Kryton Coatings International Inc., which claimed that its "Multi-Gard" liquid coating could save consumers up to 40 percent on their energy bills.

The FTC's report noted, "Dealers of 'Multi-Gard' liquid siding have agreed to settle Federal Trade Commission charges that ads claiming their product provided consumers with an insulation value of R-20 were unsubstantiated and violated federal law." (The R-value of 20 refers to resistance to heat loss.) The report went to say that "the FTC alleged that the companies did not have a reasonable basis for making the claims."

If the insulation claims are invalid, you may wonder what else contained in the advertisements are either not true or lacking key information. Personally, I have other specific problems with these liquid coating products.

For instance, in addition to all of the other advertising statements, these companies claim that their products have superior bonding properties. These properties, the companies say, allow the exterior coating to stay attached to a surface for a very long time with very little fear of peeling, blistering or chipping.

That claim, however, is sound only if the liquid spray product is applied to a fresh, clean surface that has no previous coating. But many existing homes have been painted with traditional paints. Each layer of paint in addition to this new coating forms an adhesive chain. When the weakest link in this chain fails, all of the coatings applied to this weak link- including the miracle-liquid-siding/ceramic coating - can peel and fall away from your home.

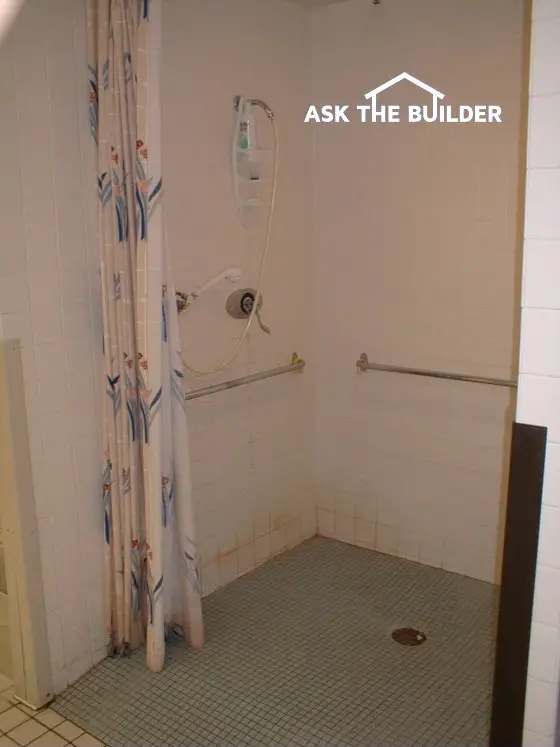

A big, hidden danger with these products is their ability to trap and hold liquid water. Water can get behind wood siding, brick, stucco, etc. that is covered with a plastic or plastic-like coating. If it is not allowed to escape quickly, this liquid water can spell serious trouble for any house that has wood framing, wood by-product sheathing, wood or wood by-product siding, etc. Once the water contacts these materials, it can fuel the growth of fungi that can rot the wood framing members, and mold that may possibly cause health problems.

Many of the products claim "perm ratings" slightly greater than ordinary house paint. The perm rating is a scientific measurement of a product's ability to allow water vapor to pass through it. The higher the perm rating value, the better your house breathes. These products tend to have perm ratings of 20 or so. Many standard air and water infiltration barriers that are beneath siding, brick and stucco have a perm rating of 80 or more. The exterior finish of a home should have a perm rating of 100 or more so that water vapor can escape readily to the atmosphere.

What's the future of these exterior coating products? It's hard to say, but you can bet that they're paying attention to the FTC statement concerning Kryton. Don't be surprised if they start to tone down their ads with respect to energy savings or promote other aspects of the product that may get your attention.

Be very careful of these products, especially when the sales pitches talk about long life and extended warranties. These claims mean nothing if you intend to change the color of your home in the future or the company goes out of business.

Having a maintenance-free home is desirable, no doubt, but be very careful of products that can't do what they say or may actually create hidden damage to your home.

Author's Notes:

Here are additional emails from consumers and people who actually own businesses that apply the products:

"I just read your article on Miracle Liquid Coatings to replace house paints. Thanks SO MUCH! I just had a sales rep from one of these companies come out (Liquid Siding of Florida) to give me an estimate. Our session was cut short (as I will soon explain), but I thought I would pass on several statements that he made.

First, he said that traditional house paint has had lead and mercury removed, seriously limiting the lifespan of paint. In fact, he said that in Florida, latex house paint will only last 3 years! Second, he claimed that his product would last 25+ years. The only reason that they can't claim longer longevity is because they've only been using this type of product for 25 years. Third, and this is what caused our session to be terminated, he said that it was company policy to create a bid and make the presentation only if BOTH homeowner's (i.e. my spouse and I) were present! I've encountered this tactic before and I refuse to do business with such organizations." Steve Hall

"I am a Liquid Siding dealer in North Carolina and I was researching the internet for information regarding the product I sell and apply. After reading your article, I am a little concerned about some of the information that you are providing your readers.

I am not going to deny the fact that Kryton did have an issue with the FTC as that is true. The issue on that controversy though was not whether or not Liquid Siding did act as a thermal barrier or not. The issue at hand was controversy over the actual technology that was involved. Kryton advertised an R-factor which as you know is a resistance factor. The FTC determined that Kryton could not advertise an R-factor because the thermal coat in the 4- part system does not work on a resistance factor but on a reflective factor.

Also, the thought about applying the coating on previously painted surfaces is unfortunately incorrect. Kryton manufactures a product called Spray and Shine and is used in the first step in the application process. We put Spray and Shine on the substrate first and let it set for 20 minutes. This allows the pores of the substrate to open up and at the same time loosens the dirt and kills any mildew or mold and its spores within the substrate. We then pressure clean the surface and set the house to dry for a few days until the moisture content is below 15% before we apply the surface conditioner.

If you would like independent lab reports from some of the top researchers in the nation please let me know and I will have them mailed to you promptly. I am not trying to attack you maliciously in anyway, I am just trying correct information regarding our product.

When Kryton first started selling dealerships they unfortunately sold a few territories to people that had difficulties sustaining their business. Liquid Siding dealers however, are the only dealers in the permanent coating industry that has seen sustained growth for 5 straight years. We are currently number 7 out of 500 in Qualified Remodeler magazine doing over 22 million dollars worth of business last year. This year we are poised to surpass that number again."

Best Regards,

Joseph LaRochelle

Here is another email received from Pam Carter, TN.

"Dear Tim,

We had liquid ceramic siding applied to our cedar siding in 2003. It has been peeling for several years and the company that did the work is no longer in business (surprise). We would like to REMOVE the liquid ceramic paint from the cedar but are afraid of completely ruining it by scraping or using chemicals not meant for this type of product. Also,our home was built in 1984 and the cedar used was not of very good quality.

We used all of our savings to have this done and have not been able to replace the money yet, so we cannnot afford regular siding. Is there anything you can suggest for us to do as our home is becoming a real eye-sore in our neighborhood? We would appreciate any input you can give us.

Thank you for being there for us.

Sincerely," - Pam Carter