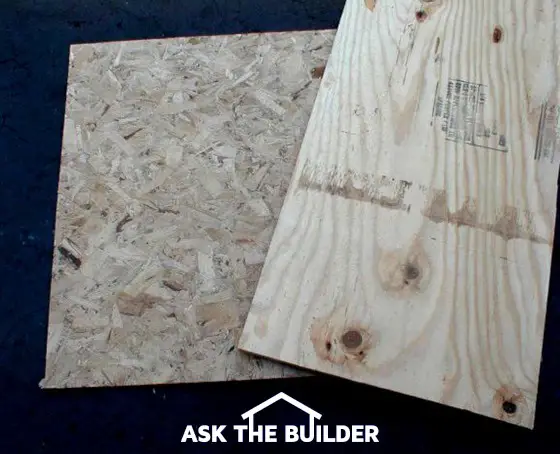

Plywood and OSB

DEAR TIM: I am getting ready to build a new home and wonder about the difference between traditional plywood and the newer oriented strand board (OSB). Is one better than the other? Is my builder using OSB to save money? Are there special precautions one should take after installing either product or can they get wet on repeated occasions? What about cost? Harvey R., Marshall, MI

DEAR HARVEY: I'll bet the same sort of consternation existed when plywood was introduced years ago as a substitute for solid wood sheathing. The passage of time and success stories from millions of installations have clearly shown plywood to be a proven performer. Production figures indicate that OSB has finally been accepted by builders, remodelers and homeowners. OSB manufacturers produced 26 million square feet of OSB this year (2006). In comparison, plywood manufacturers only produced 16 million square feet of plywood.

In many ways plywood and OSB are virtually identical. But in many respects they are quite different. Possibly the most important thing to realize is that when each product is manufactured according to strict guidelines and standards, they both exhibit superior strength and long term performance properties. You can count on both plywood and OSB for strength and stability as long as your builder follows all installation recommendations and purchases the right product from the start.

Plywood is made by shaving thin strips or plys of veneer from logs. Over 70 different species of trees can be used in plywood. After the veneer has been dried and graded, adhesive is applied to the wood strips. Each layer of veneer is oriented at 90 degrees to the one just above or below it. The glued pieces of veneer are then placed in a hot press. The heat and pressure allow the glue to penetrate deeply into the wood fibers producing a lasting bond. The layering or cross lamination of the plys is vital as it gives the plywood superior strength and stiffness. The cross layering also minimizes expansion, contraction and eliminates splitting.

OSB is made in the basically the exact same fashion. Instead of using large sheets of solid wood veneer, thousands of 3 and 4 inch long strands of solid wood are combined to make each sheet of OSB. High technology manufacturing equipment has the ability to orient the strands so they overlap and interlock at a 90 degree angle. Each strand of wood is completely coated with a high performance resin glue. After the OSB leaves the hot press, you have a structural engineered wood product that maximizes our natural resources and has superior high strength characteristics.

Rain falls on many, many homes as they are being built. In fact, rain storms left standing puddles of water on my own home's plywood sub-floors for days. The plywood was not affected long term because I used the right grade. Make sure that you use plywood or OSB that is stamped EXPOSURE 1. This labeling is your guarantee that waterproof resins and glues were used to bond together the wood. EXPOSURE 1 plywood and OSB are made to withstand repeated rainfall with little or no damage during a normal time frame construction project. To prevent rot and loss of strength, they must be allowed to dry and then have permanent protection from moisture. If you want plywood or OSB that can be permanently exposed to weather and rain, then purchase those products that bear the EXTERIOR stamp or label.

Some OSB panels react differently from plywood when they get wet. When OSB is manufactured the cut edges are sealed with a special waterproof paint. Carpenters destroy the watertight integrity of OSB each time they make a cut that exposes wood fiber edges. These cut edges are prone to swelling after they get wet. It is possible to seal these edges after they are cut, but it may be tough to find a carpenter willing to take the time to perform this extra step.

Lumber products are true commodities. Prices of these products can fluctuate wildly with changes in supply and demand. Currently where I live the prices of plywood versus OSB are very close. A piece of one half inch plywood that a builder would use on a roof or a sidewall only costs $1.02 more than a similar piece of OSB. A sheet of 3/4 inch sub-floor plywood costs just $4.38 more than the same sized piece of OSB. If you desire to use plywood on your new home, the extra cost may only be several hundred dollars.

Column 304

2 Responses to Plywood and OSB