Wood Epoxy Works for Rot

Wood Epoxy Rot | This wood rot happened because there was no flashing on top of the beam. Wood epoxy and a new flashing will save it. The galvanized screws act as pins to ensure the epoxy filling never comes out. The epoxy is sticky and bonds to the wood, but why take a chance? I've always been a belt and suspenders type of guy. Copyright 2021 Tim Carter

Wood Epoxy Rot Works Great - Long Work Time

My guess is you’ve seen wood rot before. If not, I’d wonder if you lived in the Atacama Desert, possibly the driest place on Earth. Wood rot is fueled by water which is why it’s so important for you to keep all untreated wood in and around your home dry.

Keeping wood dry is easier said than done and all too often you may discover wood rot before it’s so bad that the wood must be replaced. If so, there are wonderful products available to you that allow you to replace the rotted wood with a filler that you can paint or stain.

Can You Use the Epoxy To Make Structural Repairs?

That said, keep in mind that repair products like this are not meant for structural repairs. This simply means if the wood rot is happening in a beam or a column that supports one end of a beam, you need to make the repair with a piece of wood that will have the strength to support the weight above it.

Four years ago, I traveled 3,000 miles to help a really good friend with quite a few items on his honey-do list. This friend invests his time every now to ensure my websites are running smoothly and it was time for me to reciprocate. Fortunately, he lives in southern California and the weather was perfect.

My friend lives in an association and the houses all have a distinct southwestern look with some fake beams that protrude out from under the roof overhangs. When installing the beams years ago, the original builder made a mistake. Even though southern California doesn’t get much rain, rain does fall on these beams. One of these faux beams was showing signs of significant rot.

The rot could have been prevented if the builder or carpenter had formed a simple cap on top of the beam using a piece of aluminum flashing. The aluminum would have acted as a roof on top of the decorative wood beam deflecting any rain to the ground instead of sitting on top of the flat beam. Done correctly, only a trained eye would have seen the edges of this flashing. Most people would think nothing of it.

What Products Did You Use in California?

Here are the two products I used at my friend's house:

This is PC Petrifier wood hardener. It comes in different sizes. This is the gallon jug. Get this size if you have to repair lots of wood rot. CLICK ON THE PHOTO to have this delivered to your home.

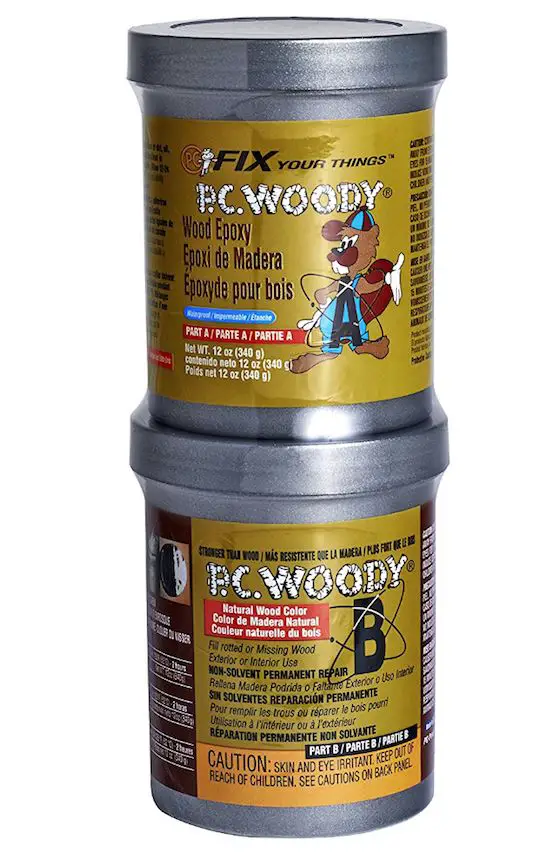

This is PC Woody. It's a fantastic two-part epoxy that's very sticky. It's easy to sand once hard. CLICK ON THE PHOTO NOW to have it delivered to your door.

What Builder Mistakes Caused Your Rot?

I share this with you because I want you to think of what went wrong at your home. What mistake did the builder make that caused your wood rot? You need to be able to remedy this after you make the repair so your repair work is not done in vain.

Missing or Ill-Fitting Flashings Biggest Rot Cause

My friend’s faux beam had a large piece of wood missing from one side. There were also cracks and holes on top of the beam and on the end that had to be filled. I decided to use a waterproof epoxy product that can be sanded and painted once cured. This two-part epoxy is easy to work with and is affordable.

Are Exterior Spackling Compounds Good?

There are exterior spackling compounds that can be used that require no mixing. I’ve tried one of the newest ones at my own home in the past two years and it failed miserably.

I had some deep gouges in the handrail that is part of the steps leading down to my dock. I knew the spackling would fill the low spots, but I was concerned about the holding or adhesive quality of the spackling compound. Sure enough, after just 18 months, the spackling could be scraped off with your fingernail. This would have never happened had I used the epoxy I installed four years ago in California!

How Did You Fix the California Rotted Beam?

Once I removed all the soft rotted wood from the sides and top of my friend’s beam, it was time to reinforce the wood. We had an assortment of galvanized coarse-threaded drywall screws at our disposal. I drove several long ones into the hole. These would act like steel rebar inside of concrete.

I then used some short screws in the large side hole. I drove these so the heads would be below the finished surface of the wood but well exposed within the hole. These would help hold the epoxy in place and act as anchors when completely surrounded by the epoxy. The bugle shape of the screw head would guarantee the epoxy would not fall from the hole.

If you don’t want to use screws as I did, then you need to excavate the wood so the bottom of the hole is larger than the top. Dentists employ this simple trick so fillings don’t pop out of your teeth. Road crews should do the same, but almost never do, to ensure asphalt doesn’t pop out of potholes.

The epoxy I used had plenty of work time. It was easy to force it into the holes and cracks. I used a variety of small and wide putty knives to get it as smooth as possible. The smoother you get it at the start, the less sanding you need to do to once it cures.

Column 1428