Flexible Gas Lines- Are You Serious?

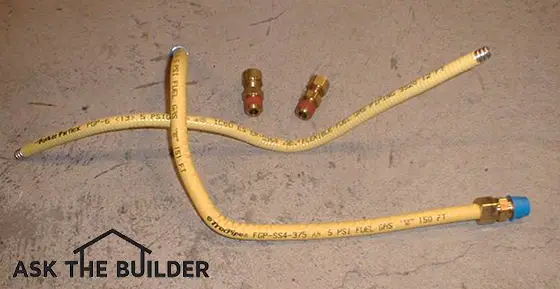

Flexible Gas Line | Here's a flexible gas line. These are two short pieces of the flexible stainless-steel gas lines or CSST. You can practically tie it in a knot it's so flexible. If you have lots of pipes to run, this may be the way to go. But before you decide, realize there's a fire and an explosion hazard with this because of lightning! Keep reading! © 2021 Tim Carter

"A flexible gas line is made from thin-wall stainless steel. It's not durable as a traditional black-iron pipe. Lightning has caused many house fires that have flexible gas lines."

Revised January 2021

Flexible Gas Line TIPS

- Flexible gas lines are safe so long as you have little lightning

- Not as durable as traditional black iron

- Require special installation tool for fittings

- Installs faster than black iron

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: The natural gas lines that are being installed in our new home are not the heavy black iron pipe. They're a new flexible stainless steel piping system that is installed like electrical wire.

What is this material? Is it safe to use? Are there advantages to using this pipe?

Can you cut into the pipe at a future date to install an added gas appliance? Is there another alternative gas piping material? Betsy F., Augusta, GA

Related Links

Easy How To Thread Black Iron Pipe Video

Pipe Threading Compound To Permanently Seal Black Iron - Great Video

Sizing Gas Lines - Tim Carter Can Draw Your Gas Line Plan

Free & Fast Bids

CLICK HERE to get FREE & FAST BIDS from local plumbers who install gas lines.

DEAR BETSY: Congratulations! You're now the proud owner of some wonderful corrugated stainless steel tubing (CSST). This material was approved for residential use in 1988 by the National Fuel Gas Code.

Are Flexible Gas Lines Safe?

A flexible gas line is an ingenious method of supplying natural gas to fireplaces, furnaces, cooktops, clothes dryers and any other gas appliance. Virtually all state and local code authorities permit its use and many contractors are finally embracing it.

I have this flexible gas line in my own home in central New Hampshire and never worry about it at all. Some plumbers will tell you it's faster and cheaper to install this new CSST piping. However, we don't get frequent thunderstorms here in central New Hampshire.

I happen to be a master plumber and given the choice, I'd install traditional threaded black iron pipe. More on this in a just a moment.

CLICK HERE to get FREE & FAST BIDS from local plumbers to install flexible gas lines in your home.

CSST Video

Watch this video to see how CSST pipe is installed.

When Was CSST Flexible Gas Line Introduced?

I remember when the material was first introduced in 1989. Many of my fellow contractors who install gas lines thought it was unsafe. Some of their arguments never made sense to me.

For as long as I have been in the home building business, we always used similar brass appliance connector tubing when gas was supplied to a clothes dryer, a cooktop, or a gas range.

Hundreds of thousands of houses have these corrugated appliance connectors in service right now. They have worked well for many years.

Why Were You Afraid of CSST?

I was afraid of CSST because of the thin nature of the pipe. There are lots of instances of houses that have been destroyed in gas fires because CSST pipe was ruptured by a lightning strike.

The pipe in the walls acts as an interior lightning rod. It's vital to follow all instructions provided by CSST manufacturers and to BOND the tubing electrically.

Errant screws or nails used to attach cabinets, trim, pictures, etc. can puncture this pipe. That would never happen with a piece of traditional black iron pipe.

Only a direct hit from a hot bolt of lightning will bore a hole in a traditional black iron pipe.

Dangers Of CSST Video

Watch this video to see what you think about the dangers of the material.

Do You Have CSST in Your Home, Tim?

The current home I live in here in central New Hampshire had these flexible gas lines installed in 2001. I've had no issues with them at all and I even had to do a kitchen remodel where I extended an existing line.

CLICK HERE to get FREE & FAST BIDS from local plumbers who install gas lines.

What are the Advantages of CSST?

The CSST has many advantages. Perhaps the biggest one is labor savings. Traditional black iron pipe takes a lot of time to cut and thread.

I know as I have installed thousands of linear feet of the heavy material. As you said, the new CSST is installed like electrical wire.

You simply pull the material between two points and cut it to length with simple tubing cutters.

Is Black Iron Gas Pipe Labor Intensive?

Black iron pipe is very labor intensive. A typical black iron pipe installation requires a professional to precisely measure, cut, and thread the individual pieces of pipe. All of these steps are very time-consuming.

It's important to realize you need to think about overall safety. Spending hundreds of dollars more for black iron pipe may be well worth it in the long run if you have a house fire.

CLICK HERE to get FREE BIDS from Plumbers to install Flexible Gas Lines.

Does CSST Create Fewer Leak Locations?

When you use CSST, you can minimize potential gas leaks. A typical black iron pipe installation has many 90-degree, tee, and coupling fittings.

These fittings are used each time you change directions or join two pieces of straight pipe together. Each of the cast fittings can be the source of a leak.

What's more, the threaded joints on both sides of the fitting can also be potential leak points. Because the CSST snakes its way around bends and obstructions as one solid piece of tubing, you only have a fitting at each end of the line. If you do have a leak, these fittings are almost always readily accessible for adjustment.

Is CSST DIY Friendly?

CSST is not user friendly for a DIY installer. It's not really a do-it-yourself proposition. Many of the manufacturers of this material require professional installers to take a short training course that familiarizes them with the small nuances of this unique gas piping system.

What are the Two Gas Line Install Choices?

These are traditional black iron pipes that I installed in 1987. Each end of a piece of pipe must be threaded. It's messy and hard work, but I must admit I sort of enjoy it. The pipe is extremely durable and rarely has a lightning strike cause a fire in a house with black iron pipe. © 20187 Tim Carter

Is it Easy to Install Additional Gas Lines?

Adding additional gas lines at a future date is not a problem if you plan for the possibility during the original installation. The CSST systems can be installed one of two ways:

- series

- parallel

The series installation resembles traditional black iron piping. A larger diameter mainline CSST pipe supplies gas to smaller branch tubes that feed each appliance. This is often the easiest system to adapt at a future date.

What is a CSST Manifold Method?

A parallel CSST manifold system mimics an electric panel. All of the gas lines that feed each appliance start at a central distribution point or manifold. To add a line in the future you need to have an extra gas port on the manifold within the panel.

Can I Use Soft Copper for Gas Lines?

Yes, you can use approved soft copper for gas line work.

If you are not able to get CSST tubing and can't handle working with black iron pipe, consider using soft copper. It offers all of the same advantages of the CSST systems.

Soft copper is approved for interior residential gas piping in many cities and towns. You don't solder it like water lines.

How Do You Make Soft Copper Connections?

Connections are made with common flare fittings that tighten with standard wrenches. The only specialized tool you need is a flaring tool made to fit the pipe size you are working with.

If you use copper for gas lines in your home, be sure to paint them yellow and label them with red lettering "GAS LINE" so a future weekend warrior doesn't mistake them for a water line!

CLICK HERE to get FREE & FAST BIDS from local plumbers who install gas lines.

Author's Notes:

If you have ANY DOUBTS about flexible gas lines or CSST, visit a local firehouse and talk to the team leader that's on duty. Visit SEVERAL firehouses to get different opinions.

In regard to your article on the CSST systems being installed in new homes. If you care to, read an article that was published in April of 2003 in the Dallas News regarding banning this installation in the city of Frisco, Collin County, Texas. Lightning strikes have caused numerous fires in residential homes as a result of CSST failing. Although the manufacturer states that it is completely safe, in fact safer than ridged black pipe, it has some serious issues. I have seen three fires in our own community as a result of CSST failure. The manufacturer accepts no responsibility for improper installation, and does not provide in any great detail, of detrimental or catastrophic failure if done so. I just saw your article and thought I would provide feedback. If you have questions on the article I mentioned, you may contact the Dallas News. Thank you for your time.

Maxwell J. Brunner

Lieutenant

Menomonee Falls Fire Department

Email- [email protected]

I responded to this very interesting email with a few thoughts of my own. My first suspicion would be that the tubing acts like a lightning rod of sorts. The thin walls of CSST might not seem to handle as much of a strike as black iron. Black iron is so much thicker that it may actually take a lightning strike better.

I suggest you look up the article in the Dallas News if you want more details.

Column 296

52 Responses to Flexible Gas Lines- Are You Serious?