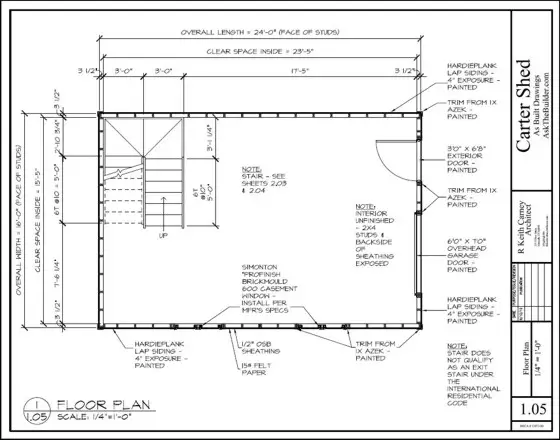

Zip System Leaking - The siding on this house is being applied directly over the wood sheathing. The sheathing has a plastic covering, and tape is required to prevent water from infiltrating into the wall cavity. Copyright 2025 Tim Carter

Zip System Leaking - The Weak-Link Tape

You prefer hearing stories rather than being subjected to a lecture, don’t you? The most popular person at a holiday party is often telling stories to a small throng of people gathered around her or him. Allow me to take you on a psychic journey over the past fifty years of my construction experience.

This column is about water. You and I need water to survive. Water, however, is the enemy when it comes to your home. Water causes wood rot, mildew, and mold. It’s so powerful that it can split rock and concrete like you might crack an egg in your hand.

I grimace each time I pass a new home construction site here in central New Hampshire. All of the builders have been drawn to a plastic-coated wood sheathing like a moth to a porch light. I predict years from now, many, if not all, of these houses will suffer from water infiltration. The cost to repair the damage will be extreme.

The Evolution of Sheathing

Sheathing comes in 4-foot by 8-foot sheets. It’s 1/2-inch thick. Many years ago, sheathing was tongue-and-groove 1x6s. This lumber was used to create the forms for the cast-concrete foundations. The lumber was salvaged and then recycled by the carpenters for the wall sheathing, subflooring, and the roof sheathing.

They 1x6s were installed diagonally on the exterior wall studs, the floor joists. It was installed perpendicular on the roof rafters The diagonal installation method added strength preventing the walls from racking.

Modern sheathing is a third-generation engineered wood product. Large sheets were developed to cut labor costs.

Version one was plywood. Version two was oriented strand board (OSB). The latest version is OSB, but it’s now coated in plastic to stop water from soaking into the wood. A special tape is required to seal the gaps where one sheet abuts another. This tape, or a similar one, is required to seal window and door nailing fins that sit on top of the wall sheathing. This tape, in my opinion, is the Achilles’ heel of the system.

Water - Resistance is Futile

The builders and carpenters of old knew all about the destructive force of water. Asphalt-saturated felt was used on top of the sheathing to protect the 1x6 sheathing, wall studs, and all the other wood inside the homes. I remodeled many old homes early in my building career that were protected by felt paper. It’s a fantastic product when installed with diligence.

Fifty years ago, felt paper was kicked to the curb by air and water infiltration barriers. These products came in giant rolls. The synthetic fabric stopped liquid water from passing through to the wood, but it allowed water vapor to escape to the atmosphere. That’s a good thing.

The plastic-coated OSB sheathing does allow water vapor transmission. It has a perm range of 12-16 perms, allowing water vapor to escape to the atmosphere.

Do you know why your roof doesn’t leak? Most homes in the USA are protected by asphalt shingles. These install just like the feathers on a bird or the scales on a fish. One overlaps another. This simple system works very well, so long as you have a roof with a decent pitch of 20 degrees or more.

This is how normal roof shingles are installed. The overlapping layers shed water. Copyright 2026 Photo Credit: Tim Carter

Your roof would leak like a sieve if you installed the shingles backwards. Imagine if the top edge of a lower shingle sat above the next shingle higher up on the roof. Water cascading down the roof would flow behind the shingle and get into your home.

The tape used on the modern sheathing is installed this way! The top edge of the sealing tape is not covered by something above it. Water that gets behind the siding or brick can travel down the OSB and get behind the tape should it detach from the plastic coating.

The tape is counting on expert installation. The tape hopes the plastic-coated OSB is clean and dust-free. The tape is counting on the installer to firmly press it against the sheathing. The tape is counting on the temperature to be between 0F and 120F.

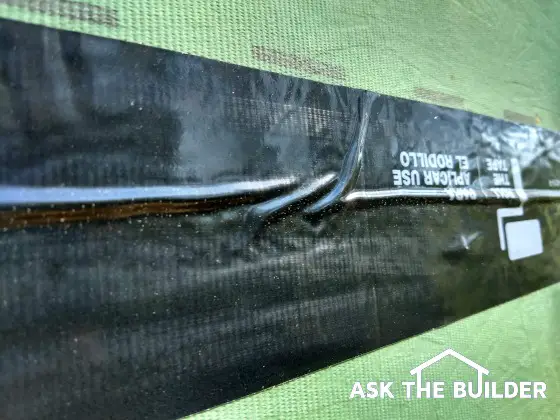

Look at the bubbles in the tape. The one bubble runs to the TOP of the tape and is an open pipeline for water to infiltrate into the house!

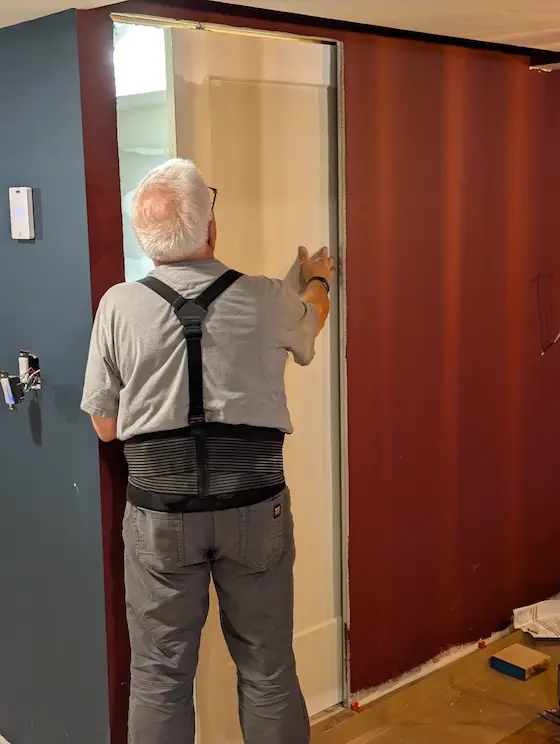

Look closely at the tape at the corner of the window! See how it's not adhering to the wall? There are any number of reasons why this happened. The tape requires expert installation techniques. Copyright 2026 Tim Carter

You, the homeowner, are counting on the tape’s adhesive to sustain thousands and thousands of repeated expansion and contraction cycles over decades. Imagine how the tape gets hot and cools down each and every day as the sun rises and sets.

It’s my opinion that this tape has not yet stood the test of time. The residential construction industry is littered with products all thought to be amazing, but over time, they fail. Think of the thousands of homes that suffered catastrophic leaks from plastic plumbing water supply pipes that become brittle and crack when subjected to the chlorine found in most municipal water systems. Think about the class-action lawsuits involving low-quality house siding made from wood dust and glue. I could go on and on and on.

I can hear you. “Tim, if this is how my builder installs sheathing, what am I to do?” I admit this is a major conundrum. I can assure you I’d never rely on this tape to prevent water from entering my home. I’d install traditional OSB and cover it with the synthetic fabric air and water barriers.

This method allows you to overlap the synthetic fabric over the top of the window and door nailing flanges. This fabric can be installed like roof shingles on two-story homes. The first-floor level is covered first. You then overlap the next row of fabric on top of the one below. The manufacturer even makes a special tape to seal this overlap.

You get one chance to get the sheathing protected the right way. Can you imagine what the cost might be years from now to repair a house where the OSB tape has failed?

This is why my Ask the Builder motto is: “Do it Right, Not Over!”

Column 1640