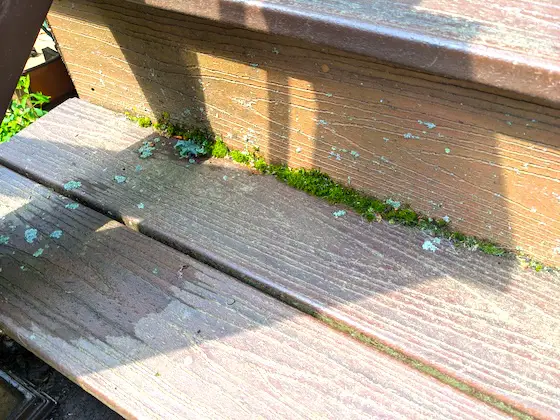

These are micro mesh gutter guards. I installed them myself ten years ago. Organic debris, algae, and moss clogged the tiny openings causing them to fail. A pressure washer restored the guard on the left to original condition. Copyright 2025 Tim Carter ALL RIGHTS RESERVED

Gutter Guard Cleaning - You WILL Be Up on Your Roof

Do you attend home and garden shows? These events are almost always held in the spring. They’re a great place to see new products for both the interior and exterior of your home.

I recall thirty years ago, when the gutter guard industry began to gain momentum. This was just after I started writing this syndicated column. New styles and gutter guard designs were popping up as fast as dandelions in my lawn. The manufacturers all said you’d never have to get up on your roof to clean your gutters again. Most of them were not telling the truth.

My home was surrounded by evergreen and deciduous trees. It was a perfect candidate for gutter guards. I had over 240 feet of gutter to protect. The first product I used was an abysmal failure.

Money was tighter than a banjo string around the Carter house at that time. I purchased a flimsy plastic gutter guard that had diamond-shaped holes punched in it. A kernel of corn could easily pass through the knockouts.

The primary reason the gutter guards failed is that the guards lay pretty much flat across the top of my gutters. I had installed my gutters somewhat high on the 1x6 redwood fascia board. I created a shelf for the leaves, twigs, dead flower blossoms, pine needles, and bits of tree bark.

Lately, I’ve seen TV commercials for a similar gutter guard made from metal. The company shows the gutter guards being installed just as I did all those years ago. I can see on my TV screen their guards creating a very flat surface.

This gutter guard has been undergoing testing for ten months. It's not allowing things into the gutter, but the flat shelf it's created is not allowing debris to wash or blow off the roof. PHOTO CREDIT: Tim Carter

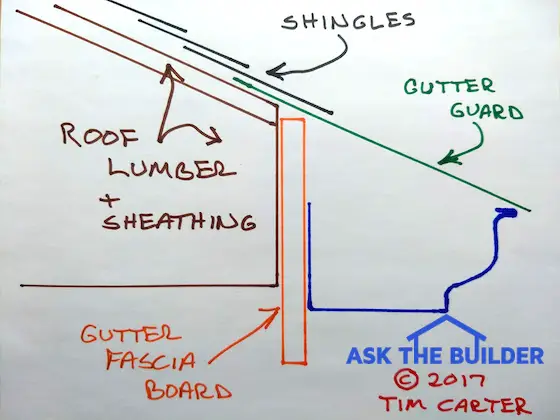

Within a year or two, my gutter guards were clogged. The debris couldn’t wash off the flat surface. Wind was useless except to blow off fresh, dried leaves. Pine needles mixed with all the other fine debris rendered the guards useless. I discovered that the top surface of the gutter guard must be in the same plane as the roof, so debris has the best chance of washing off with each hard rainfall.

Here's a quick cross-section showing how the gutter guard - in green - is in the same plane as the roofing material. The drawing is not to scale. I used to make drawings like this sitting at customers' kitchen tables. Copyright 2025 Tim Carter

I decided to test various types of gutter guards. Companies were all too happy to send me a small amount of their product to test. The vast majority of the gutter guards failed. They either clogged up, or the reverse-curve models allowed small debris into the gutter, defeating the purpose of the product!

A reverse-curve gutter guard typically has a solid top with a bullnose curve and slot running along the front edge of the guard. The surface tension of water allows it to roll into the gutter even during heavy downpours. Large debris can’t enter the narrow slot, but small things can.

I demonstrated this phenomenon at the International Builders Show years ago. A company that manufactured a reverse-curve model was exhibiting its latest product. They had a model of a small roof set up in their booth. A recirculating pump and piping delivered water to the top of the small roof. The artificial rain ran down the roof surface and into the gutter guard. The gutter delivered the water back to the pump, sending it back up to the top for another ride down the roof.

While the company representative was speaking with a builder, I went over and stood next to the model. I proceeded to tear up small pieces of paper, about the size of my thumbnail. I felt these would represent tiny leaves or parts of bigger leaves that might litter a roof. I dropped the pieces of paper onto the roof, and the next thing I knew, they were all inside the gutter. Not one of them was deflected to the ground by the magic gutter guard! When the representative saw what I was doing, he told me to leave.

A few years later, I came across a micro-mesh gutter guard. I thought this might indeed be the Holy Grail. I tested two of them. One failed simply because the manufacturer installed it, creating the same shelf I had done with my first guard. The other manufacturer insisted on lowering my gutter so that the front tip of the gutter was in the same plane as the roof. This guard worked perfectly.

That said, I had always felt that even the micro-mesh gutter guard would fail. My gut was right. I installed this same gutter guard on my New Hampshire home ten years ago. Last year, I noticed more water seemed to be coming off the gutter guards. I inspected the guards and found the ultra-fine mesh was clogged in many places by algae, moss, lichens, and a very fine black organic deposit.

I fired up my electric pressure washer. The intense stream of water restored the gutter guards to like-new condition in seconds.

Gutter guard companies and salesmen may be spewing half-truths to you. I’ve been a building and remodeling expert witness for over twenty-five years. We have a saying: A half-truth is a whole lie. You, or someone else, will be doing maintenance on your gutter guards. They will have to be cleaned at some point.

Column 1616