AZEK Aluminum Deck Post Bolts

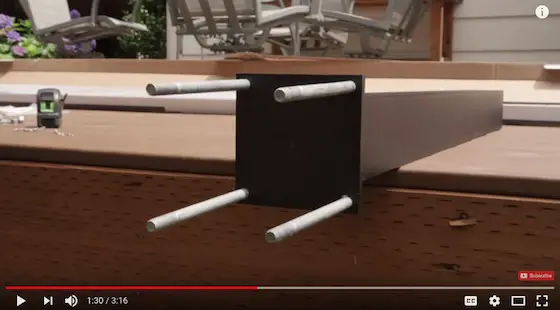

Here's a great shot of the fastening method for some Azek aluminum deck posts. The four bolts must be made from a material that will not corrode when water surrounds them and the treated lumber they pass through. Copyright 2018, Google / YouTube, Inc. Fair Use Doctrine screen capture

Published: January 12, 2018 © Tim Carter

Just two days ago, January 10, 2018, I was at the International Builders Show in Orlando, Florida. I visited the AZEK booth and was talking with an AZEK employee about bolts that should be used when installing the AZEK aluminum deck posts. (Full background story on the Builders Show in the January 13, 2018 Newsletter.

The first thing to remember is AZEK invited me to come to the booth.

Here's a screenshot of the invitation to come to the Azek booth.

It's important to realize I write a syndicated newspaper column that's still published by sixty-plus papers. In addition, I have over forty years of hands-on experience working in the field in the homes of paying customers. Another key point is I have nearly 50,000 newsletter subscribers who regularly participate in short surveys.

The combination of these three things allows me to provide a unique insight as to the wants and desires of consumers and I can identify building products or systems that might not be as good as they can be.

What's more, I'm mindful of a growing and disturbing trend of young builders, carpenters and DIYrs that aren't aware of serious structural dangers when metal fasteners come into contact with outdoor treated lumber and water.

It's basic high school chemistry.

AZEK Aluminum Deck Post Bolts Can Corrode Fast

Just before leaving the AZEK booth, the AZEK team members wanted me to see an aluminum railing system they were displaying at the show. Within minutes, I got into a tug-of-war discussion with a young AZEK employee after he showed me the cast flange at the bottom of the aluminum deck post.

The conversation went something like this:

"Do you supply the needed stainless-steel through bolts, washers and nuts with the posts?"

"No," said the AZEK employee.

What followed was a brief discourse about how the entire safety of the railing system is dependent upon the through bolts never rusting or corroding.

The through bolts are a primary structural component of the deck railing system. If they fail, the railing can be pushed over with ease.

Should this happen, a person/people could fall many feet to the ground and be seriously injured or die.

Rapid corrosion of metal fasteners happens when you mix modern treated lumber, water and normal steel bolts that have a thin zinc coating. You need special fasteners that are highly resistant to corrosion when it comes to deck railings and posts.

High-quality type 316 stainless steel is the material of choice to avoid corrosion.

Expert Witness Work Provides Perspective

I mentioned to the AZEK employee that I've been doing expert testimony work for about 15 years or more and that my most recent case involved the Brazilian Ambassador's roof on the island of Antigua.

I shared with this young man the chain of events that unfolds when a building product failure becomes the focus of a lawsuit.

Should someone be injured or die because an AZEK aluminum deck post fails because of a corroded bolt(s), one of the first companies that's going to be named in the subsequent lawsuit would be AZEK.

The first thing to remember is it doesn't matter that the aluminum post didn't fail. Fasteners are required to connect the AZEK railing to the deck.

AZEK and their engineers undoubtedly know about, or should have known, the importance of fasteners and more importantly what it takes to ensure their railing system stays safe for the life of the deck.

The plaintiff's attorney would discover in the deposition phase of the lawsuit that the AZEK engineers ran tests to ensure the railing was safe. No doubt questions would be asked as to what types of fasteners were used in the test procedures.

I know this because I've been asked countless probing questions while under oath sitting at a large wood table with a court stenographer and voice recorder capturing my every word.

AZEK, by selling a deck-railing product, is expected to be knowledgeable about what it takes to create a safe product.

That's a given. Technology has really raised the bar for manufacturers when it comes to product liability and doing a better job. AZEK has the ability to set up a Google Alert for every mention of AZEK or one of its products so it stays up to date with all that's going on.

Let's assume AZEK is named as a defendant in a lawsuit where a person died because their railing system tipped over after the bolts holding it rusted. In addition, assume this happens six months from now after this column has been published on the Internet.

As soon as the plaintiff's attorney discovers this column early in the discovery process while she/he researches all that's been published about AZEK aluminum deck railing systems, it's going to be time for AZEK to open up their checkbook. I say this assuming that AZEK continues down the pathway of not supplying the best available fasteners with their railing system.

I'm no legal expert nor am I offering legal advice to AZEK. All I'm doing is sharing my own personal experiences having been a part of lawsuits where I was an expert witness.

Imagine if this hypothetical lawsuit proceeded all the way to a trial. If you want to see how the jury might vote after they deliberate the facts in the matter, be sure to answer the question at the bottom of this column and then look at the results of others who've answered before you.

Simpson Strong-Tie Ally - Corrosion is a Real Danger

"Don't you feel it would be a good idea to include stainless-steel bolts, washers and nuts with your product so you do your best to ensure that your railing system doesn't fail?"

I went on to explain that another exhibitor at the show, Simpson Strong-Tie, had all sorts of literature and experts at their booth that would explain how deck railing posts must have the highest-quality fasteners to be safe for decades.

Simpson Strong-Tie also publishes excellent documents with great illustrations showing how to make safe connections. This is not hard to do.

CLICK HERE to see an example of how to make a wood deck railing post very safe. Pay close attention to the fact that they do include the fasteners and you can pick one that has stainless steel!

We discussed the insignificant cost of high-grade USA-made type 316 stainless-steel through bolts. For a company like AZEK to purchase them in bulk, my guess is the cost per bolt, washer and nut combo would be less than 50 cents each. This means the cost of a post would have to be increased by just $2.00, perhaps $3.00 to cover the cost of any packaging for the hardware.

Here's a typical stainless steel through bolt you might use with an Azek aluminum deck post. The bolt costs about 54 cents each. You can buy a pack of them at Amazon.com for $8.07 here in January of 2018.

Although I didn't record the conversation, I wish I had now, I'm quite certain the young man's exact response to my question above was, "Our competitors are not including the hardware and no one would pay the extra money for them."

"Would you like me to prove you wrong? I'm more than happy to do a survey of my tens of thousands of newsletter subscribers and my YouTube subscribers. Let's see what they have to say."

The AZEK employee had no interest in me doing this no-cost survey for them.

"You know what, I'm just going to do the survey on my own and I'll share the results with you. I'm willing to bet that a vast majority of consumers would GLADLY pay extra money for the correct fasteners knowing their railing system will not fail."

You don't have to have a MBA in marketing to see the huge opportunity here. Can you picture this TV or magazine ad:

"Our competitors don't include the required stainless steel fasteners with their deck posts. They just hope the contractor will use the right ones. Do you want to HOPE that your deck railing doesn't fail? Specify AZEK aluminum deck posts with included stainless steel bolts and know your loved ones will be SAFE."

But What Bolts Should Be Included?

You may think it's impossible to include the right bolts. It's not. The AZEK engineers can easily do the following:

- develop a preferred installation method for both wood and concrete situations. Believe me after framing countless decks, it's not hard to come up with a standardized method that will work in almost all cases. CLICK HERE to see how the Simpson Strong -Tie engineers convey the best way to install their hardware.

- for wood, show the size, number and placement of blocking pieces as you see in the video above. Also show the exact type of corrosion-resistant fasteners required to secure them to the deck floor joists. If the blocks fail, then so to will the railing no matter what bolts are used!

- for concrete, show the correct stainless-steel stud anchors, epoxy if necessary, and the minimum distance the holes must be from the edge of concrete slabs.

- create a short installation video showing how to install the blocks and bolts - put a sticker on the post advertising the video.

A Company That Does it Right

Just three weeks before going to the Builders Show I had the delightful experience of installing a product from a company that understands consumer wants and values their time and safety. I've installed thousands of products in my career and when I opened the box and saw all the included parts, a gigantic grin appeared on my face.

Pay close attention to the clear packaging just under the floodlight in this photo:

Here's what you get with the Ring Floodlight Cam. You even get EXTRA parts in case you're a klutz and drop something. The orange screwdriver works to tighten the white finish nuts that secure the floodlight to the galvanized steel baseplate in the photo. Copyright 2017 Tim Carter

What you see is the Ring Floodlight Camera. It's got all the parts you'd ever need, and even a few extra things in case you drop something!

Brilliant. You bet I'm willing to pay $2 more to save a trip to the hardware store! You bet I want the best screws to install the floodlight so it doesn't fall, short out and cause an electrical fire at my house killing me and my loved ones! Kudos to the folks at Ring!

Ladies and gentlemen of the jury, it's now time for you to weigh in. Answer the following question and let the chips fall where they may:

99 Responses to AZEK Aluminum Deck Post Bolts