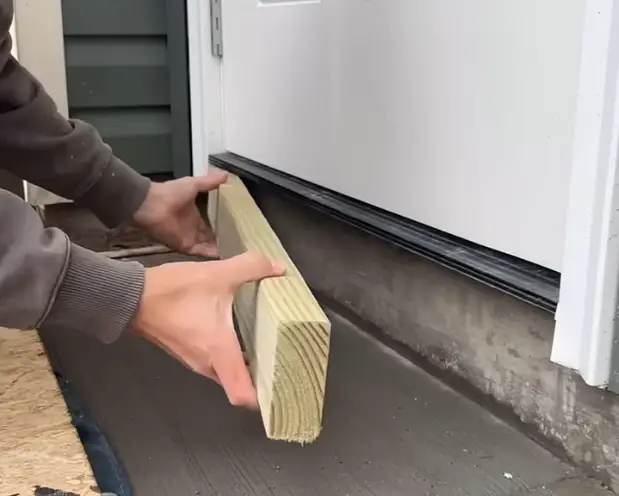

The paint on these steps and the wood porch above it lasts for only two years. I believe I know why it fails. Copyright 2024 Tim Carter

Exterior Paint Peeling - Water, Water Vapor, Dust, Dirt, and Oil

Are you frustrated with peeling exterior paint peeling? Maybe it’s a fence, a picnic table, a bench, your house siding, a shed, outdoor furniture, or a pergola. You might also share Jan’s misfortune. She visited the Ask Tim page of my AsktheBuilder website requesting help.

Here’s what Jan sent to me:

“Our problem now is our front porch that is subject to the elements here in Des Plaines, Illinois. I am SO tired of repainting every other year or at a minimum, touching up worn spots every Spring. The paint flakes off the railings, stairs, and even floorboards. We have gone as far as stripping it down to bare wood, using primer and then two coats of oil base porch paint. Unfortunately, it lasted no longer than the water-based paints, which were easier to work with. The snow and rain hits the stairs and railings but not usually the decking. Although, a few times the snow has blown up the five stairs to our door. Any idea what we can do to save our backs and knees?”

Jan sent me a set of photos that allowed me to diagnose her exterior paint peeling problem in just seconds. She lives in an older home. The porch is raised above the soil as are her wood steps.

This is Jan's front porch. It's no wonder paint won't adhere to the wood. Copyright 2024 Tim Carter

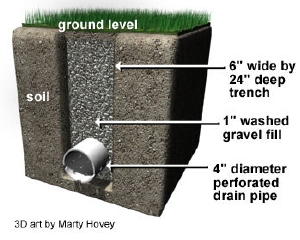

The underside of the porch has little or no ventilation. Walls, covered with the same wood shingles as the house, extend from the porch down to the soil. Illinois is east of the Mississippi River and gets quite a bit of rainfall each year. Invisible water vapor wafts up from the soil and enters the wood. The paint doesn’t stand a chance. Here’s why.

John Pendrey the Chemist

I started a summer business with a good friend after I graduated from high school. We painted houses in the summer. John went on to get a PhD in chemistry. He spent his entire career working in a lab for one of the largest paint companies in the USA.

When John was in graduate school, he started gravitating towards a career in the paint industry. One day we were eating lunch together and he handed me a scrap of paper with a chemical formula on it. He asked, “Do you have any clue what this common item is?” I was a geology major not a chemist, “I’m clueless. What is it?”

John responded, “It’s the formula for common yellow carpenter’s glue you use all the time. Now look at this other formula.” He handed me a second scrap of paper with a long formula.

I looked and it was nearly identical to the glue one. I said, “Well, this must be the white glue kids use in school.” John said, “No. It’s the chemical formula for a very standard water-base exterior house paint.”

At that instant of time, a light bulb went off in my head. Why of course, paint does stick to things like glue. It’s hard to get out my clothes, it’s hard to get off my paint brush ferrules as well as ladders. Paint is just colored glue.

Paint Expands and Contracts

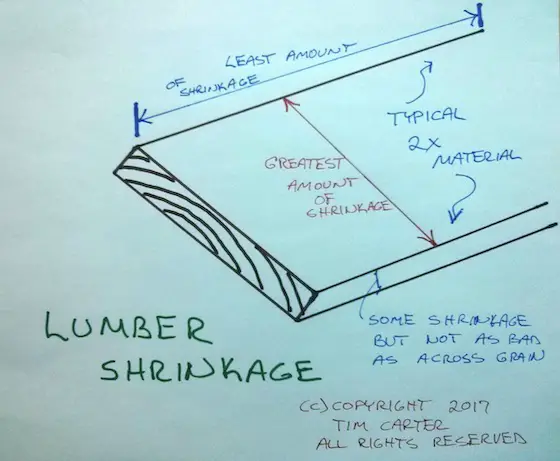

Paint expands and contracts. So does metal, plastic, and wood. But different materials have different expansion and contraction rates. Of all the common things you have in and outside your home, wood and plastic move the most. Heat causes plastic vinyl siding to expand. Water, or water vapor, causes wood to grow in size.

Water Vapor and Vapor Pressure

It gets worse. Water can travel with ease through wood. If you recall some of your high school physics, you might remember a class on vapor pressure.

In Jan’s case, water vapor from the soil is entering the underside of all the wood that makes up her porch and steps. The odds of the original carpenter painting and sealing all the sides of each piece of wood before he built the porch are as high as you guessing the Mega Millions lottery numbers.

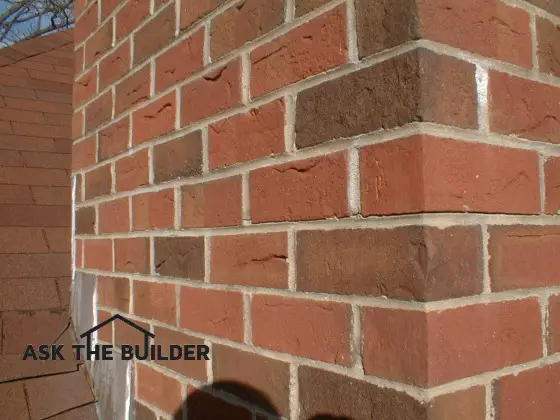

Water seeps into Jan’s porch wood and works its way to the underside of the paint. When the sun hits the painted wood and warms it, it creates a difference in vapor pressure. The vapor must get out so it pushes the paint off the wood.

If your wood gets wet from rainfall or lawn sprinklers, it can swell. The swelling may be greater than what the paint can expand. If so, the adhesive bond between the paint and the wood fails. This is but one reason paint peels.

Read Paint Can Labels

Other common reasons for peeling paint are on the paint can label. Can you recall the last time you read the label on a paint can? Most say, “Apply to a clean, dry, dust-free, and oil-free surface.”

Adhesive tape doesn’t stick well to dusty or dirty surfaces. I’m sure you’ve had tape fail. It’s no wonder paint will fail if a thin coating of dust or dirt is on the surface you’re trying to paint.

Always clean things you’re about to paint as you would your car. Get a bucket of soapy water and rub the surface with a sponge or brush and then rinse and dry. Good luck!

Column 1558