How to Build a Shed | Framing the walls of a shed requires minimal carpentry skills. This shed is being built to look exactly like the house. Look just below for the finished photo of this shed. © Copyright 2017 Tim Carter

How To Build A Shed TIPS

- STOP and think about the correct size - WATCH video below

- Use great plans to help you get it right - GET THEM BELOW

- WATCH how-to videos below

- Treated lumber & plywood floors are best

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: I need to know how to build a shed. As I looked for leaf-raking tools in the debris field formally known as my garage, I realized I need a storage shed.

I went out and looked at different outdoor storage sheds at dealers and home centers, but I want to build my own.

Are wood sheds the way to go? Brian F., Lancaster, PA

DEAR BRIAN: It is going to be very difficult in this short column to teach you how to build a shed.

How Hard is it to Build a Shed?

There are hundreds of individual steps involved and some of the most important are in simply planning your storage shed. For example, you may want to talk with your wife and build both a combination storage shed and garden shed at the same time.

I did this two years ago, and it has turned out to be a huge success with my wife.

This is the finished shed from the photo at the top of the column. My house is a Queen Anne Victorian home, so the shed is a perfect match. Look at the photo just below of my home. The shed is at the end of my driveway.

This is my home. You can see the shed is a perfect match even the fancy shake shingles in the gable end!

Can You Call Me To Help Me Build a Shed?

Yes, I can call you to help you build your shed. I do many consult phone calls each week and they save homeowners lots of time and money. CLICK or TAP HERE to set up an affordable consult phone call.

Most recent customers to order a phone consult: Manu, Alexandria, VA | Patti, Ft. Worth, TX | Warren, Hamilton, OH | Sandra, Bend, OR | Brandon, Rapid City, SD | Alice, Plant City, FL | Loreli, Worcester, MA

Free & Fast BIDS

CLICK HERE to get FREE & FAST BIDS from local companies that will build a shed for you in no time.

What is the Biggest Shed Mistake?

The biggest mistake I see homeowners make is they don't think about how big the shed should really be. Watch this simple video to get an idea how SIMPLE it is to calculate the size you really need.

Can You Build A Shed Without Plans?

I built my entire shed without any plans but it's not a good idea for you to try it. I was able to do this because I've built so many things.

You'll not be able to survive without plans. I had a fantastic architect draw up the plans of my shed AFTER it was built.

Why? So I could SHARE with you how to do it.

You don't have to build the EXACT shed I have. You can modify the plans to fit what size you want / need.

The plans will help you VISUALIZE what you need to do. I've never ever seen such detailed shed plans in my career.

You can BUY THE SHED PLANS NOW for just $9.95. You print them out on regular paper.

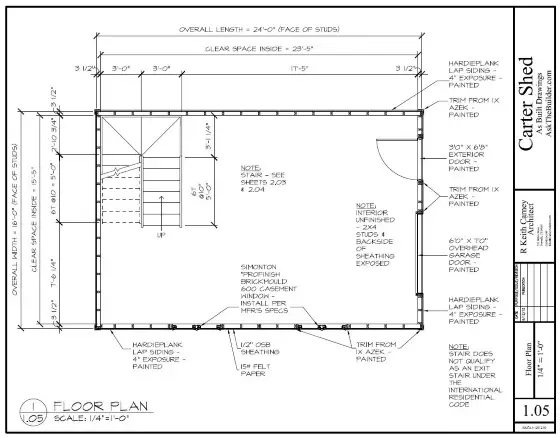

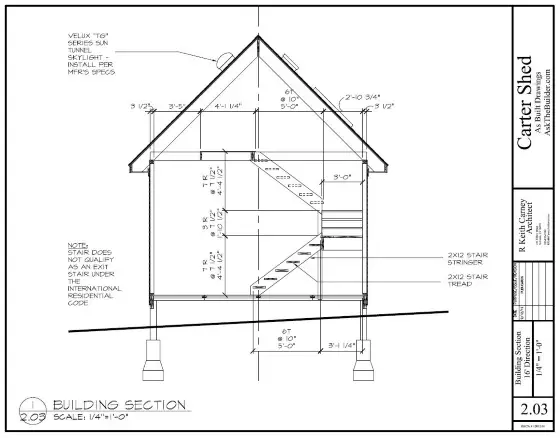

Here are just TWO of the SEVENTEEN pages in these fantastic plans. I know you CAN'T READ them, but you will be able to see all the print and measurements when you DOWNLOAD the real ones.

This is the floor plan. It shows you where EACH STUD goes!! CLICK THE IMAGE NOW TO BUY THEM. INSTANT DOWNLOAD.

This is a page showing a cross section of the shed. There are 17 pages to the set of plans!! CLICK THE IMAGE NOW TO BUY THEM. INSTANT DOWNLOAD

What is the First Step in Building a Shed?

The first place to start the how-to-build-a-shed process is with your local government officials. You need to see how your zoning laws deal with sheds as well as your local building codes.

For example, where I live the building department is not concerned with sheds that are under a certain square footage. You may discover you do not need a building permit.

Should the Shed Have a Wood Or Concrete Floor?

A shed is best to have a concrete floor, but wood works well too. Be sure the wood joists and the plywood are treated lumber so they don't rot.

Once you have learned you can build the shed in compliance with all laws, then make a decision if the shed will have a wood floor or a concrete slab. I've built sheds both ways, and feel one with a wood floor works well if you build it using the right materials.

If you want your storage shed to be problem-free for years, you need to make sure it has a great foundation that will not move. I prefer working with wood because it is affordable and easy to cut, move and erect.

Should Sheds Be Protected From Frost Heave?

Structures built in climates where the ground freezes must be protected from frost heave. When soil freezes, the water in the soil expands.

This can lift the soil dramatically causing all sorts of structural stresses for those structures built without frost-protected foundations.

CLICK HERE to get FREE & FAST BIDS from local companies that will build a shed for you in no time.

Is a Turned-Down Slab a Good Idea?

A frost-protected foundation can be full-length poured concrete footers that extend below the level that frost penetrates or round concrete pads that support treated-lumber posts.

I like using the wood-post method as it resembles building a traditional wood deck. For a simple outdoor shed, you may only have to dig four 16 or 24-inch diameter holes for the entire foundation.

What Type of Wood Floor Should Be Used?

The wood-floor system should be made with treated lumber that will resist wood rot and any attack by wood-destroying insects. I also use treated-lumber plywood for the floor of my storage sheds. This way any water that drips from tractors, tools or other things will not cause any damage to the shed flooring structure.

You can get treated plywood at any local lumberyard. Most homeowners have no idea this great product exists. it makes a fantastic shed floor.

Should I Use a Treated-Lumber Bottom Wall Plate?

When you frame your shed walls, use ordinary framing lumber but always use a treated lumber bottom plate. In case water does get into the shed, this treated lumber bottom wall plate helps resist wood rot.

Be sure to use plywood or oriented strand board on all of the corners of the walls of the shed. This makes the walls very strong so they resist racking forces caused by roof load and wind.

Are Trusses or Common Rafters Best for a Shed?

You can buy prefabricated roof trusses for the roof structure, but cutting simple roof rafters is not that hard. If your budget is tight, you will probably discover that framing the roof without trusses is the better alternative. You will simply have to learn how to cut simple rafters.

CLICK HERE to get FREE & FAST BIDS from local companies that will build a shed for you in no time.

Should the Walls be Covered with Felt Paper?

Be sure you cover the exterior walls and roof with overlapping asphalt felt paper before you apply siding or shingles. The felt paper will prevent any wood rot in case a leak develops over time.

Watch this short video about how well felt paper works.

Can I Use a Narrow Overhead Garage Door?

A 6-foot-wide narrow overhead garage door is an excellent choice. They don't blow open, they're affordable, and come in many styles.

When you decide on doors to get into and out of your storage shed, give a hard look at smaller overhead garage doors. Everyone who see the six-foot-wide metal overhead garage door in my garden shed marvels at it. Here's a video of my small shed overhead door:

It provides ample room to get my garden tractor in and out, is lightweight and easy to open and close and it is attractive. It only took me 90 minutes to install this gorgeous overhead shed door.

Can I Build The Shed By Myself?

Many of the actual tasks that you will do to build the shed can be done alone. You will probably need help lifting some of the longer walls that are framed on the floor. It is dangerous to try to lift and secure the walls by yourself, although it is possible to do.

You may want some help as you apply sheathing to the roof rafters or trusses.

Should the Floor & Walls Be Square?

Be sure to take your time to get the floor of the shed perfectly square and level. If you take the extra time to do this, it will pay off in spades as you frame the walls and install the roof. Out-of-square foundations or floors will cause you fits through the entire building process.

Watch this video to see how to square up floors and walls.

CLICK HERE to get FREE & FAST BIDS from local companies that will build a shed for you in no time.

Column 697