Truss Uplift and Ceiling Crack TIPS

- Wood trusses move as the seasons change

- Bottom of truss lifts up taking drywall and walls with it

- Simple metal clips can prevent truss uplift

- Clips can be installed in existing homes.

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: Cracks have begun to appear where the walls meet the ceiling in the top floor of my home. These cracks are most prominent along the walls in the center of the house.

I've also noticed that the baseboard has lifted up from the floor in other places. These cracks seem to close up on a seasonal basis.

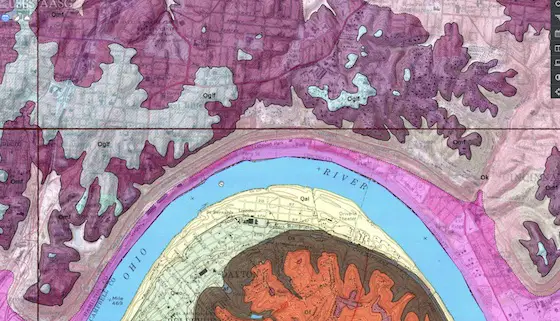

Sturdy, prefabricated wood trusses were used to build my roof. What's happening? What if anything can be done to prevent the unsightly cracks? Ben - Traverse City, MI

DEAR BEN: There are a multitude of things that can be causing these cracks.

Trusses Move

The first thing that comes to my mind is a phenomenon called "truss uplift". Although truss uplift causes approximately 20 percent of problems like yours, it's something you should consider.

Undersized beams, expansive clay soils, wet floor joist lumber that shrinks, and other structural problems also can cause the cracks you see.

Flat Bottom Chord Curves

Most simple roof trusses consist of a flat horizontal member called a bottom chord. The sloped portions of the truss that form the roof surface are called the top chords.

However, the bottom chord can develop an upwards curve as the seasons change.

Temperature & Humidity Battle

The bottom chord in your house and many others like yours is probably buried in insulation. Because the truss is touching the warm ceiling drywall below and the temperature of the insulation close to the ceiling is far warmer than the attic air temperature, the wood truss is none too happy.

Meanwhile, the upper portion of the truss is exposed to cool and drier attic air. Since wood is a hygroscopic material, any of the wood that makes up the truss that's exposed to the air in the attic releases moisture in the winter months.

The bottom chord that's buried in the insulation tends to have a higher moisture content because it thinks it's much warmer in the attic than it actually is.

Bottom Chord Bends

The differences in moisture content cause the truss to bend. The lumber of the truss exposed to the cold, dry air shrinks and pulls up on the flat bottom chord causing it to lift and curve upwards.

The greatest amount of upwards movement is in the center of the truss. As the truss moves upwards, it takes the drywall ceiling with it.

This might explain why your cracks are larger as you get closer to the center of the house.

Up Go The Walls

If, for some reason, the interior walls are nailed more securely to the truss than the floor, the truss will actually lift the entire wall. This will account for gaps you might see at your baseboard trim.

Preventing Truss Uplift

There's a way to prevent this problem. If you're building a new house, don't allow the carpenter to nail the roof trusses directly to any interior walls

Instruct him to use handy metal L-shaped truss clips. These simple, inexpensive devices attach directly to the top of interior walls.

This simple clip is all that's needed to prevent truss uplift. The bottom is nailed to the top wall plates. A nail is driven through the slot into the side of the bottom chord of the truss. Be sure this nail is NOT driven tight. You want the truss to be able to flex up and down without pulling up the wall with it. CLICK THE IMAGE NOW TO HAVE THESE CLIPS DELIVERED TO YOUR HOME WITHIN DAYS.

The long leg of the clip contains a slot. A nail is driven through the slot into the side of the truss. The head of the nail is driven so it is just short of touching the metal clip.

This allows the truss to move up and down independently of the wall.

Drywall Hanger ALERT!

The drywall hangers must cooperate as well. Don't allow them to nail or screw the drywall directly to the trusses within 16 inches of an interior wall.

They can fasten the drywall to pieces of wood that fit between the trusses or metal clips that attach to the top of the interior walls.

Because the upward truss movement occurs over a period of weeks or months, the drywall will flex at the corners. Cracks should become a thing of the past.

Repair Existing Homes

If you have an existing home that suffers from truss uplift, it can be corrected with some effort. You need to climb into the attic area and get to work before it gets too hot.

Use a cat's paw tool to remove nails which connect trusses to interior walls. Install the L shaped clips in their place.

After the truss clips are in place, nail a board on top of each interior wall which overhangs the wall by at least 1 inch on each edge. This will act as a bumper when the truss attempts to lift the drywall next year.

Fix The Nail Pops

When this occurs, you will probably see nail pops develop near the interior partitions. Take a large nail punch and drive these nails completely through the drywall.

This will release the drywall from the trusses at each partition. Patch these holes with regular joint compound and hope that the problem disappears.

Column 169