How To Pour A Concrete Footing TIPS

- Soil must be strong

- Bottom of footing below local frost level

- WATCH step-by-step videos below!

- Steel rods in concrete are a must

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter

This spring you may have ambitious plans to build that long-awaited DIY room addition, shed or detached garage.

Good for you!

Many a homeowner just like you has successfully completed one of these smaller projects.

All structures need a great foundation so they can stand the test of time.

Foundation walls almost always are supported by a footing, or footer.

Footing Is First

The footing is almost always the first thing one does when building anything.

The bottom of the footing is what touches Mother Earth. It's no different than your foot, hence the name.

CLICK HERE to get FREE & FAST BIDS from local foundation contractors who can put in your footing.

Spreads Weight

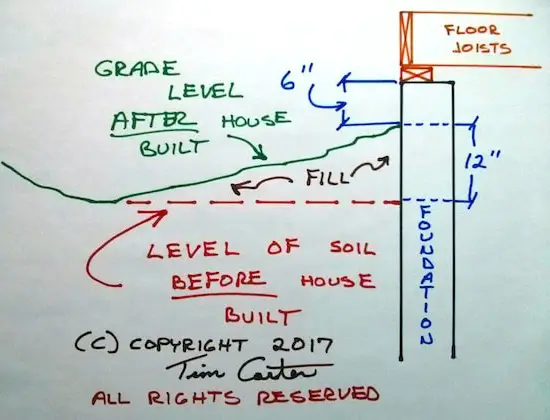

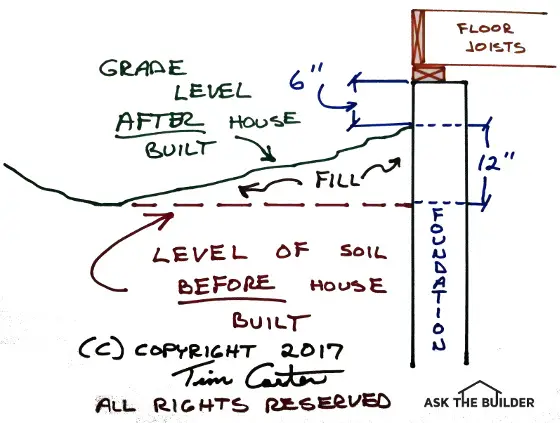

The purpose of a footing is to spread out the weight of the structure onto the soil. The foundation wall rests on this footer. Most common footings for houses, room additions, detached garages, etc. are 24 inches wide and no less than 8 inches thick.

You can access a handy quick start guide for concrete footers with more tips and a full tool list here: Concrete Footer Quick Start Guide

Degree of Difficulty:

Concrete Footing Step-By-Step Videos

Watch these videos to see the entire process of forming and pouring footers. You may be doing a trench footer where trench walls become the forms. These require you to stand down in the concrete if you have a frost depth that exceeds 24 inches.

After watching the videos, then continue to read for extra detail that may have been skipped in the videos.

Permits & Frost Depth

Check with your local building department concerning building permits, and the frost depth in your area. The bottom of the footer needs to be below the frost depth. It’s always a great idea to go just a little deeper than recommended.

Call 811

Be sure you locate and identify any underground utilities before you dig. Call 811 and have all utilities marked so you don’t get hurt or cause neighbors to have problems if you slice into a buried electric, water or gas line.

Must Be Square

Be sure you double check the footer is square before you dig. Layout the foundation on the ground before digging.

When the diagonal measurements are the same in a square or rectangular foundation, it’s square! Watch this video about squaring up a footing or a wall.

Watch this video to see a neat trick using some long 2x4s. You can build a box that represents the actual outer shape of your finished foundation. Make sure the lumber is straight, square it up and then spray paint a line about 8 inches on the outside of the box to represent where you need to dig your trench.

If you footing is going to be 24 inches wide, most are, and your foundation is 8 inches thick, that means the footing extends 8 inches beyond the outer line of your foundation wall.

Digging Is Work

You can dig by hand, I’ve done it for many a footer, but tool rental businesses now rent very small excavators that can fit in a small yard. You don’t need a full-size backhoe to dig a shallow footer.

Great Soil

If the soil smells like rotten eggs, is squishy or you sink in it even when you get down to the desired depth, STOP and get a professional opinion. You may have to dig deeper to get to STRONG soil or you may have to install piers. Smelly soil often means there's lots of organic material rotting in the soil. This will cause a foundation failure in the future.

Steel Is A Must

Footers need long pieces of reinforcing steel. One-half-inch diameter, #4, is almost always sufficient. This steel needs to be continuous through the entire footer and be held up at least 3 inches from the soil. Overlap splices at least 16 inches.

CLICK HERE to get FREE & FAST BIDS from local foundation contractors who can put in your footing.

8 Inches Thick

The footer should be at least 8 inches thick. Most architects call for a footer to be 20 inches wide, but I always poured mine 24 inches wide. Wider is better because it spreads out the weight of the building onto the soil

Must Be Level

You can just pour the concrete in a 24-inch wide trench if you like. It’s key the concrete is very level.

Drive vertical pieces of reinforcing steel into the soil every 4 feet in the center of the footer as leveling reference points. Use a laser level or builder’s transit to get the tops of these pins at the same height.

Helpers A Must

Have plenty of help on hand when the concrete truck arrives. Be sure to have spare wheelbarrows in case one breaks.

Don’t overfill wheelbarrows as concrete is very heavy. Consider renting a small machine with a bucket that you can use to make trips from the concrete truck to the footer.

Boots & Tools

Wear rubber boots if you’re working in the trench to level the concrete. Concrete will cause burns to skin, so wash off any as soon as possible. Use a simple wood float or magnesium float to smooth the concrete.

Hard Work

No one task, other than digging the hole and wheelbarrowing the concrete, is really hard in this job. It’s all a matter of common sense and thinking the job through.

Column HT007