How to Prevent Contractor Mistakes - Would you know that this new floor installed over an existing floor would cause extreme illness resulting in thousands of dollars of unnecessary medical bills? Copyright 2023 Tim Carter

How to Prevent Contractor Mistakes - Phone Call Help and Due Diligence

I feel it’s my job to save you as much money and time as possible on every project you plan to do at your home. While it’s a noble quest, I’m thwarted each day by two or three things. First and foremost, if my incoming email from homeowners like you is a statistically relevant cross-section of the population, there are thousands of contractors who produce less than acceptable workmanship.

The next problem is you. It’s tough-love time. Each autopsy I do for homeowners that are victims of poor workmanship contains a toxic mix of trust and hope. It’s natural for you to trust that the person you hire will do a good job. But hope is an emotion that should only be reserved for things you can’t control like the weather and winning lottery numbers. Don’t ever hope the job goes well. Do your due diligence to ensure a happy ending.

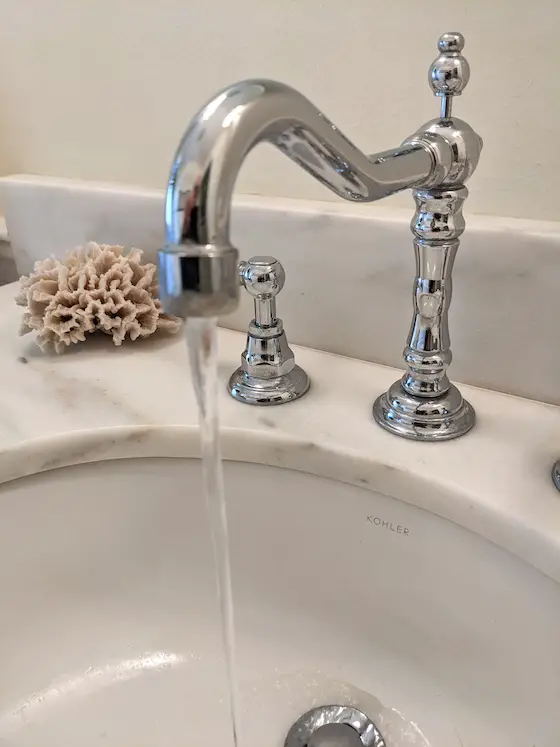

Allow me to share with you two true stories. The first one happened just last week. Several days ago a young woman my wife and I know from church reached out to me. She's our cantor and was desperate for plumbing help. All of a sudden a leak occurred in a lower-level ceiling of her condo.

Knowing how to prioritize leaks, I asked, "Is water dripping constantly?” She replied, “No. It's just a water spot that appeared that wasn't there a few days ago.” I knew it was not an emergency as a pinhole leak in a water supply pipe would cause a stream of water or a constant drip. I texted her, "I'll be there tomorrow at 11:29 AM."

Once I arrived at the woman's condo and looked at the stain, it was time for questions. I asked, "What happened here in the past few days that was unusual? Have you had strangers in the house or contractors?” She responded, "Oh yes, just a few days ago a flooring contractor finished installing a new laminate floor upstairs."

We climbed the flight of steps and I walked over to the spot just above the water-stained ceiling below. I was standing inside a half bathroom. The young woman added, "The flooring contractor took off the toilet and put it back down after he installed the flooring. He said everything would be fine."

While the flooring contractor’s intentions may have been good, he broke the all-important toilet gasket seal and buried the toilet flange with the new laminate flooring. Now, each time the toilet is flushed, water splashes around under the toilet, and some leaks out around the toilet flange. It then passes through the hole cut in the sub-flooring for the drain pipe. Gravity then deposits the water on the drywall fastened, for the time being, to the bottom of the floor joists.

This young woman only reached out to me because she couldn’t get local plumbers to return her calls. How many hundreds of dollars of extra expense were caused by the flooring contractor’s lack of understanding of how to properly re-seat a toilet? So you know, I’m going to fix the flooring contractor’s mistake for free.

Two years ago a different homeowner hired me to diagnose why his wife was seriously ill. Three different doctors couldn’t figure out the cause of her sickness. After talking with the husband on the phone for just 15 minutes, I told him I was positive she was being poisoned by methane gas.

I simply asked questions that the doctors might not have posed. As the phone call ended, I told the homeowner to open the windows in the house and keep them open until the repairs could be made. His wife started to feel better within hours.

A different flooring contractor made the same mistake. He installed a new marble floor on top of a ceramic tile floor inside a half bathroom. Once again, this contractor broke the all-important seal between the toilet and the flange. The homeowner paid me to specify how the repair was to be done and to be present when a plumber came out to reseat two toilets in the house. It ended up being an eight-hour consult as his home was 80 miles away.

A remodeling contractor based in Texas subscribes to my weekly newsletter. In my most recent newsletter, I shared the story about the young woman. He reached out to me recounting several similar horror stories about water leaks caused by flooring contractors. He finished by saying, “I caution my customers not to let the flooring guys mess with the plumbing. Really smart tile/flooring guys know better and state up front they do not remove/reinstall plumbing fixtures.”

You can prevent bad workmanship, to a large degree, by investing the time to discover how jobs should be done. Yes, it takes work to do this. It’s not easy. By doing it, you remove hope from the equation. Don’t forget that I offer phone coaching to let you know all the things that can go wrong on one of your upcoming jobs. The husband of the sick wife wrote me a heartfelt note thanking me for putting an end to his wife’s misery. Save a stamp and let’s talk before you start your job!

Column 1495