Ten Most Common Roof Leak Locations

Roof leaks are a nuisance for many homeowners. They can be difficult to diagnose - that is a fact. To make matters worse, different weather conditions will produce leaks in different locations.

The vast majority of roof coverings operate using the principal of gravity. This can be a big help in locating a leak source. However, horizontal roof boards can trick you. A leak may actually be eight to 10 feet sideways from where you see the wet ceiling or spot in the attic.

Finding the source of some leaks is easy. Others will require detective work and possibly a garden hose and an inside spotter. If you don't feel comfortable on a roof, you will have to find an honest roofer to assist you. Sometimes this can be as hard as finding the smallest leak! Here are some tips that may help you find a pesky roof leak:

The Field of Shingles

If your roof is older, it is possible that the leak is within the roof field. This means the expanse of shingles, slate, shakes, whatever. If your roof is asphalt, then you can walk around with ease. Other materials such as slate, concrete tile or clay tile may not be so forgiving.

You can crack roofing if you walk on it, so be careful. With regular shingles, look at the tops of the vertical knockouts. Look for missing colored granules. Look for cracks. Possibly a nail has backed itself out of the roof sheathing. Simply take your time and hunt.

Free & Fast Bids

CLICK HERE to get FREE & FAST BIDS from local contractors that will help you find leaks in your roof.

Valleys

A valley is a line where two roof planes intersect. Here in Cincinnati we use a metal flashing in the valleys. Some areas use rolled roofing. Other places simply lace the shingles together. Valleys can be big problems if you do not trim the shingles correctly.

When you trim a shingle for a valley you end up with a chisel point on the end of the shingle. If a second cut is not made to make this point like an arrow point, then water can travel along the top of the shingle and find its way inside your house. The shingle wrapper tells you how to make this simple second cut.

Head Wall Flashings

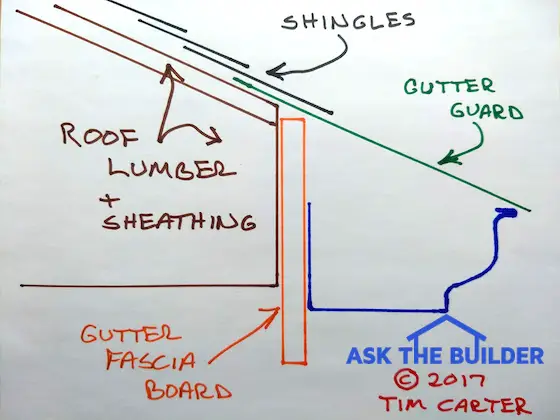

Some roofs stop at a vertical wall. A metal flashing must be in place to direct water streaming down the wall away from the stopping point of the shingles. This flashing may be behind wood siding or in front of a brick wall. The flashing should extend over the shingles at least three inches.

If the wall is brick or other masonry, the flashing must bend and extend one inch into a mortar joint. Tar, caulk or roofing cement should never be used in conjunction with these materials. If you see them, it is a sign that someone tried to patch a leak!

Wall Step Flashing

Some roof leaks happen at step flashings. You find these flashings where a roof climbs alongside a vertical wall. As each row of shingles is laid, a step flashing is installed over the shingle next to the wall. Part of the flashing turns up on the wall and the other portion gets covered by the next row of shingles.

Look for rust or holes in these flashings. In reality, if all is well, you will be able to see only the smallest portion of these flashings.

CLICK HERE to get FREE & FAST BIDS from local contractors that will help you find leaks in your roof.

Chimneys

These devils are the source of many a leak. Chimneys contain four different types of flashing. All must be right or you will have a leak. Plus, the counterflashing that goes into the brick mortar joint must be right.

A hairline crack above the flashing can allow vast amounts of water to run behind the flashings. Look for soldered corners of flashing that might have broken or have holes. Do not use caulk to repair these flashings!

Plumbing Vent Flashings

Newer vent flashings are a concern of mine. Many of these incorporate a rubber seal with an aluminum flashing. The rubber can fail in as little as 10 to 15 years. Look for cracked rubber around the plumbing pipe.

The flashing should dive up and under the shingles that extend up roof from the middle of the plumbing vent. The bottom half of the flashing should be exposed and actually cover the shingles.

Furnace or B-Vent Flashing

These flashings are basically identical to plumbing vent flashings. However, they sometimes have a metal storm collar. These simply fit tightly around the vertical pipe that exits the roof. If they become loose, the storm collars can cause leaks.

Ice Dam Leaks

Ice dam leaks plague people in the snow belt. These leaks can happen even if everything on your roof is just fine! Ice dams block the natural flow of water down a roof. The water begins to back up under flashings, shingles, tar paper, etc.

Once water begins to flow into the house, it can drip for days. The only means of prevention is to install membranes under the roofing. The membranes won't stop the ice but will stop water leaks if installed properly.

Wind Blown Rain Leaks

Wind driven rain can also be a major problem. Once again, you could actually have a good roof and wind will drive water up and under your roofing materials. The only lines of defense are tar paper and the ice dam membranes.

If you have metal valleys, you may want to hem the edges. This means that the hidden edges of the valley actual have a 180 degree bend. This creates a channel that directs wind blown rain back to the bottom of the valley.

Roofing cement under shingles on the edges of roofs that face the wind are also a good idea. Don't underestimate the power of a 70 mph sustained wind-driven rain.

Non-Roof Leaks !

Sometimes you think you have a roof leak when in fact the roof is fine. Attic condensation is a prime example. High humidity can cause condensation and "rain" to fall in your attic. It can also make the underside of the roof sheathing look wet. You think you have a leak instead.

Chimney crowns can develop cracks. The inside surface of the chimney gets discolored or the plaster bubbles. You think a roof leak is the cause.

Siding can be missing above a roof. This can cause water to enter behind head flashings. Be a good gumshoe and snoop around for the leaks!

CLICK HERE to get FREE & FAST BIDS from local contractors that will help you find leaks in your roof.

Column B188