Room Additions

They come in all sorts of shapes and sizes. In fact, they are much like people. Room additions can be plain and simple or exceptionally extravagant. I have built small room additions - less than 80 square feet and I have built ones that came close to 2,400 square feet. I'm sure you have seen a variety of room additions yourself. They are as different as snowflakes.

A Huge Undertaking

Constructing a room addition is really the same thing as building a small house. The only problem is that it is much harder. The connection details are tough. Working around people and finished surfaces requires extra care. Dust and utility (electric - plumbing) interruptions must be kept to a minimum. There are many things you have to consider with room additions that never are an issue when you build a new home from scratch. Basically, room additions are a pain in the you-know-what.

The Right Height

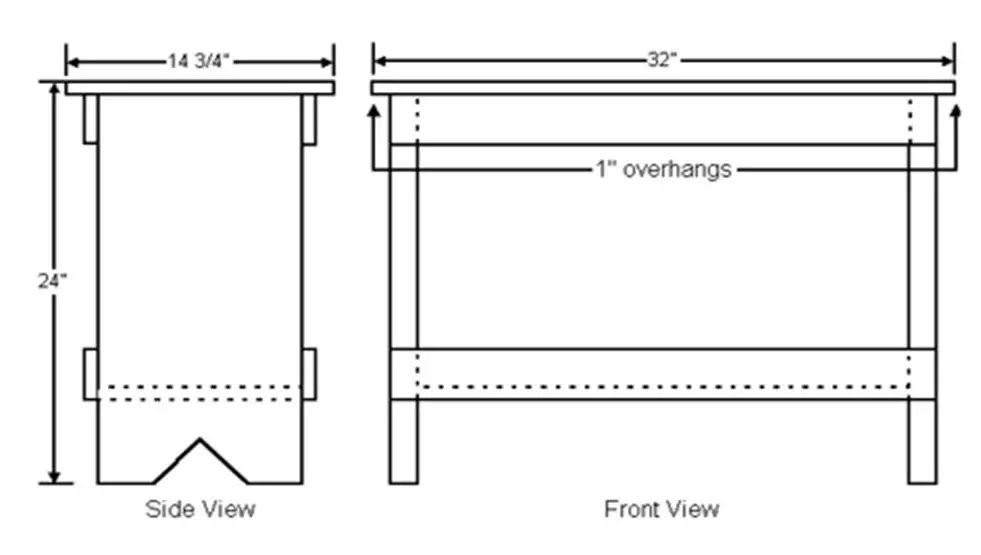

One of the most crucial aspects of room additions is making sure the floors meet. I can't tell you how many room additions I have visited where the floors do not line up. There is a hump or a dip. The mistake can usually be traced to a failure of not calculating the foundation height from the point where the "break-through" or "connection" will be. All too often, the contractor will calculate the floor height at a corner or some other obscure point.

The trick is to cut a hole through the side of the existing house exactly where the archway or doorway will be that connects the two rooms. Cut a hole and remove all the exterior wall materials until you can actually see the subfloor or finished floor material inside the house. From here you can then calculate where your top of foundation will be. I always draw a picture and back calculate down to the top of the new foundation.

For example, I determine the thickness of my new finished flooring, the thickness of the subflooring, the floor joist height, the treated lumber foundation sill thickness, and the 1/8 inch for the foam sill sealer! It all adds up.

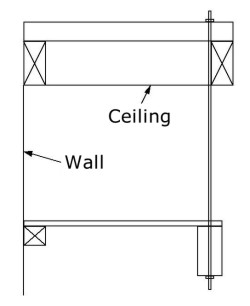

Wall Heights and Roofs

Do you want the roof line, overhang, gutter board, soffits etc. to match perfectly on the outside? It takes some work for this to happen. For these elements to match, you need to take apart the exterior of upper wall treatments to "see" where the actual finished wall ends and the bottom of the rafters begin.

To make a roof line up you must determine the existing roof pitch, the heel height of the rafters as they pass over the outer edge of the rough building line frame, and the rough overhang depth. It is important to keep in mind the exterior wall treatment of the room addition. If you are not going to match the addition to the existing house, then you must treat the exterior finished walls as the same material. Confused yet? See, I told you building room additions was not for the fainthearted!

Crawl Space Ventilation

A large majority of room additions have crawl spaces. To eliminate moisture problems and dampness, you need to cover the soil in the crawl space with a high performance vapor barrier. I have discussed these in a past column and Builder Bulletin. The clear 6 mil poly you were thinking of using is not high performance! Visit my website for this information.

Heating and Cooling

Are you thinking of simply extending your heating and cooling system into the room addition? Think again! If your original furnace and air conditioner were sized accurately for the original house, I doubt they will provide enough "conditioned" air for the new addition. If you are adding several hundred feet of new floor area, you can count on a significant upgrade of your heating and cooling system. You don't believe me? Then make sure the heating and air conditioning person does a new heat gain and heat loss calculation!

Room additions are a lot of work. Don't underestimate the complexity of this job!

Related Articles: DIY Room Addition in 7 Weeks, Room Addition Task Timing, Room Addition

Column B220