Ceramic Tile Shower Seat Design

Every customer of mine that has requested a shower seat has not been disappointed. The reason is simple. Shower seats allow you to really enjoy a relaxing aquatic episode.

When I am really tired after working all day, it is a delight to turn on the warm water and sit down. It is totally different than sitting in a tub.

Shower seats also make a great place to store kids' toys, shampoo bottles and hair care enhancement fluids. Seats also make a great place to plant your foot when shaving your legs. How would I know? Well, uhhh.... my wife tells me so! Yeah, that's it!

Design and Construction

When building a traditional ceramic shower, the incorporation of a seat is simple. All that is required is additional floor space.

CLICK HERE to get FREE & FAST BIDS from local ceramic tile contractors.

You can get by with a simple 12 inch deep seat if necessary. This means that a four foot by three foot shower space will work.

The seat is simply framed with regular lumber. The sub-seat is just a piece of 3/4 inch plywood. It is nailed to a mini-wall that creates the front of the seat face. A simple wall cleat on the backwall beneath the plywood supports it from falling.

You can also create a very fancy seat by installing a thick piece of marble or granite between the two shower walls. A decorative bracket may have to be incorporated under the seat in case you use a thin piece of stone.

This method will require professional assistance. You will need to make sure the seat is supported properly by the cement board or other hidden stainless steel clips.

Seat Options / Materials

You can build the seat out of any material that is unaffected by water. I happen to prefer marble. Many marble supply houses have scrap pieces that will do just fine for an average seat. All they have to do is make sure it fits and has its front edge polished.

Try to select a marble that compliments or blends with your tile color. If you take your time, you will find a beautiful marble that will become the focal point of the shower.

Be sure to consider small corner shelves or a long narrow shelf five feet off the floor behind/above the seat as well. These small pieces of marble are excellent accents.

If you can afford granite, give it a serious look. A black granite seat in a white tile shower is breathtaking. I know, I have installed several.

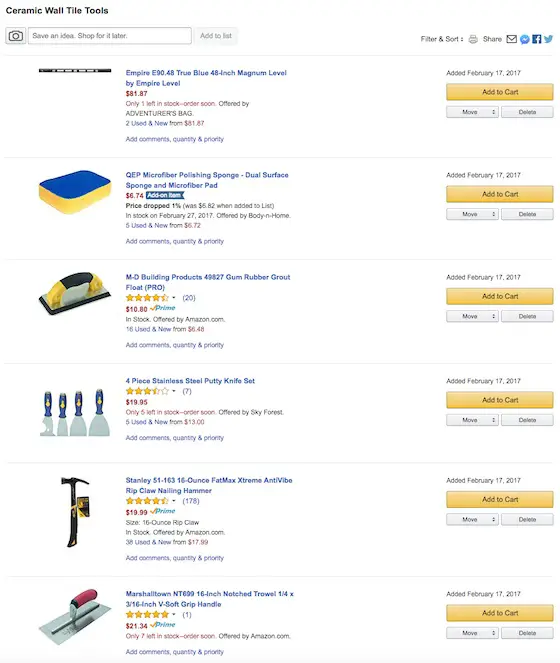

Tile Tools

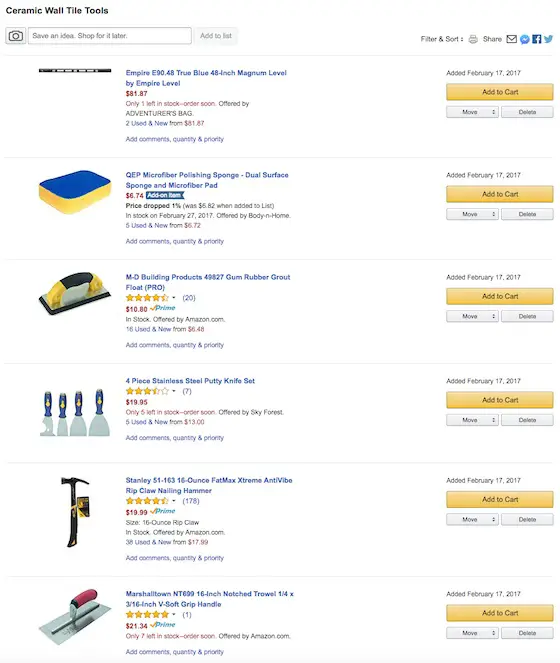

What tools do you need to complete a simple ceramic tile job? Here's a list:

- tape measure

- pencil

- tile cutter

- nippers

- a 1/4 by 1/4 inch v-notched trowel

- a hammer

- some 6d finish nails

- 8 lineal feet of straight 1/4 inch wood lattice strip

- putty knife

- 3-inch wide-bladed scraper

- grout sponge

- rubber grout float

- several buckets

- accurate 4 foot level

Click the image below to BUY all, or some, of the tools in the above list.

CLICK THIS IMAGE NOW TO ORDER ALL THE TOOLS YOU NEED TO DO CERAMIC TILE.

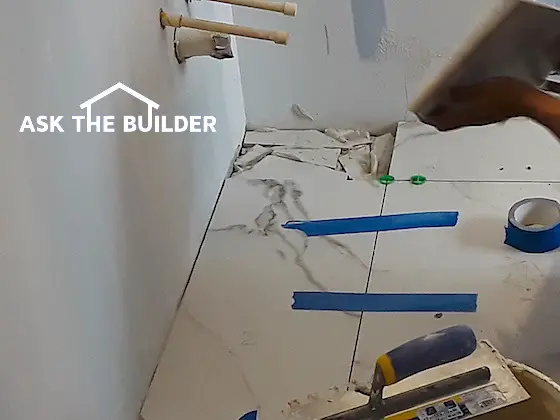

Waterproofing a Seat

If you decide to install a bench seat, you will need to make sure that water does not get behind the seat.

It is easy to waterproof this arrangement. You frame the seat first. Always be sure to calculate the correct height and width for comfort reasons. Use a bucket or standard chair to derive measurements.

CLICK HERE to get FREE & FAST BIDS from local ceramic tile contractors.

Waterproofing is accomplished by using the vinyl membranes that are used beneath ceramic tile floors. Simply purchase and install a continuous sheet from the floor, up the front of the bench over the seat and up the back of the seat wall about six inches.

The membrane is only nailed at the top edges. You will have to penetrate the front bench wall surface with nails when you install the vertical piece of cement board. This is not a problem, as I have yet to develop a leak in my shower after 15 years.

The marble or granite seat simply lays in a thin bed of cement mortar on the vinyl membrane. If you choose to install ceramic tile on the seat, just cut a piece of cement board first and install it as you would the granite or marble. Never nail through the cement board into the wood sub-seat!

Shelves...The Extra Touch

The perfect compliment to a ceramic tile shower or tub area is a set of corner shelves or a long shelf in a U-shaped shower.

These marble trim pieces are usually very inexpensive. For example, I can purchase a four inch wide by 36 inch long piece of white marble for about $15. It makes a great place to store shampoo bottles or a soap dish.

Triangular corner shelves are also attractive. Cut out a template from cardboard and take it to the marble shop. The shelf must fit tightly against the cement board. It is only supported by the 1/4 inch tile. This is plenty of support once all the tile is installed and grouted.

Always try to bargain for the shelves. Often they can be cut from a scrap piece of marble or granite. Check your size before ordering. You want to make sure that it is not too small.

Visit your local ceramic tile store. Look through brochures. You may spy a photo of a shelf, seat or other trim piece that will add function and beauty to your ceramic shower. Don't be too conservative, take a chance!

CLICK HERE to get FREE & FAST BIDS from local ceramic tile contractors.

Related Column: Ceramic Shower Seat

Column B168