DEAR TIM: I need to construct two retaining walls, one in my garden and one along side my driveway. The height of both walls needs to be about 4 1/2 feet tall. Also, the ground above the garden wall will not be level, it will slope upwards from the wall. I have an ample supply of rocks which I can fashion into a wall without mortar. Will this work? What do I need to be concerned with? T. H.

DEAR T.H.: You need to be concerned with several things. The first of which is to check the yellow pages for a structural or civil engineer in your town. I suggest that you arrange for a consultation.

Retaining walls are not simple. The job they are expected to do, hold back soil, involves several critical factors. These factors can be different in each situation.

Basically, engineers look at four things: the proposed height of the wall - the slope of the ground above the wall - the type of soil behind the wall - additional weight applied on the soil above the wall (cars, trucks, structures, etc.).

The tall concrete pier halfway down the wall is plumb. Note how the segmental retaining wall has a cant or backwards lean to it.

Gravity is a primary force working against retaining walls. The creation of a retaining wall alters the dynamic equilibrium of a hillside. Prior to construction of the wall, everything was just fine. The retaining wall is now put in the position of doing the work of the soil that was taken away.

Retaining wall height is extremely important. As the height of a wall increases, the forces which want to make the wall tip over or slide are increasing at an exponential rate.

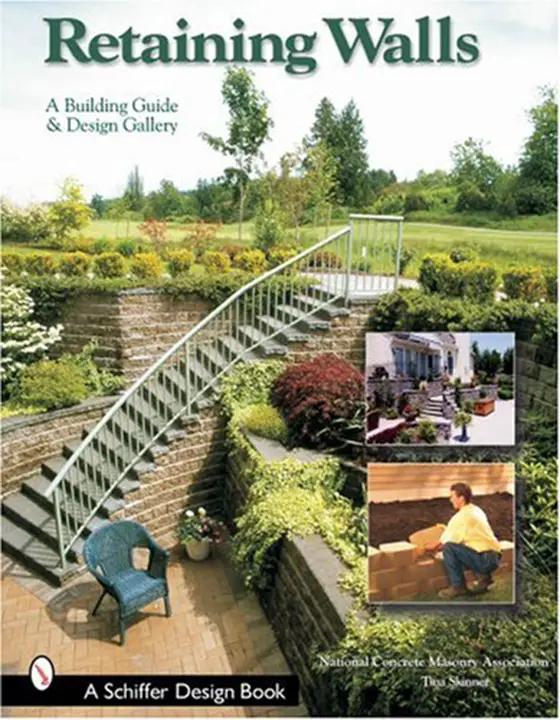

CLICK THE IMAGE to get an essential guide on building retaining walls for whatever situation you may be dealing with.

This means that if you double the height of a retaining wall, the forces pushing against the wall could be 3 or 4 times as great. The forces behind retaining walls higher than 3 feet begin to get very impressive.

Need to build a retaining wall? Build a sturdy, durable wall with my Retaining Walls Checklist. I offer a 100% Money Back Guarantee.

The slope of the soil behind a wall also is important. The wall in your garden not only has to contend with the soil behind the wall but also the soil upslope from it. The weight pressing against this wall quite possibly will be measured in thousands of pounds.

Soil drainage capabilities are also important. A soil which retains water will put additional loads against the wall during rainy seasons. For this reason, retaining walls should be designed with excellent drainage systems within the soil behind the wall.

Install drainage tile, washed gravel backfill, geo-tech fabrics to prevent siltation of the gravel backfill, and weep holes within the wall to allow water to escape from behind the wall.

Often, retaining walls are created for parking lots, driveways, etc. As vehicles pass over the ground above the wall, they add additional weight which engineers call surcharge. In some cases, this weight can be extreme.

For example, imagine a fully loaded concrete truck on your driveway. These trucks can, in some instances, weigh 35 tons. Poorly engineered walls can not resist this type of loading.

Your situation, I feel, calls for a different type of retaining wall. The wall you are proposing is commonly referred to as a gravity wall. It relies on its own weight to resist the tipping and sliding forces working against retaining walls.

CLICK THE IMAGE to view a wide selection of books and guides on how to build, drain, and design retaining walls.

The engineer you call will probably suggest a cantilever wall, counterfort, or buttress wall. All of these can be faced with the stone which you have available.

Many retaining walls require vast amounts of time, labor, and money. Don't gamble if the wall is higher than 3 feet. The services of a qualified engineer will afford you great peace of mind. If you want a user friendly retaining wall system that minimizes labor, then read Stackable & Segmental Retaining Walls.

Read my column Retaining Wall Basics and Blacktop Cracks for a reader's question on a failing retaining wall.

Column 037