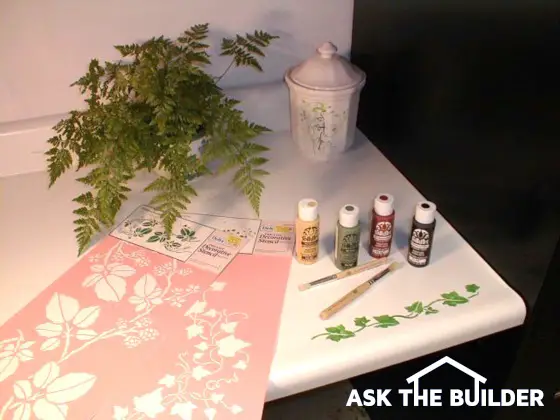

You can buy cool stencils at craft stores. Use the right paints and a little bit of clear water-based urethane, and you are set.

Painting Countertops

DEAR TIM: Our home is 20 years old and the kitchen countertops are plastic laminate, butcher block design, popular in the 70's and early 80's. We would like to redo the worn countertops to a more modern look. We absolutely can't afford to install new tops of any type. Is it possible to create a new, durable surface and not spend more than $75.00 on materials? Ken W., Plano, TX

DEAR KEN: This is your lucky day my friend! You are going to be able to radically change the appearance of those humdrum plastic laminate tops into magnificent works of art in just several days. I know this is going to sound absolutely crazy, but you are going to paint the countertops. This is a job that virtually anyone can do and if you take your time, the tops will be the talk of the town.

Not only are we going to paint the tops, but I suggest you incorporate the extensive use of stencils to create decorative multi-colored patterns that will make your kitchen counter surfaces one-of-a-kind. Stencils are available at many large scale craft stores. You can get ones that create a strand of ivy around the entire counter, fern and regular tree leaves, country kitchen scenes, different fruits, and floral patterns. If you use several colors with the stencils, the finished look will be stunning. Use the stencils on the front edges and vertical back splashes of the countertops if you want to maximize their effect.

If you don't like stenciled patterns then I highly recommend that you think about try a faux finish look. You can use multiple paint colors and different items such as newspaper, sponges, rags, sheet plastic to create textured and dimensional looks within the paint.

Author's Note: I have a wonderful step-by-step eBook that shows you how to get professional results when painting cabinets. It is easy to follow and affordable. Plus, you get the eBook instantly!

The paint in and of itself when applied to a horizontal surface will not be able to withstand the abuse of daily kitchen tasks. It will scuff and scratch easily. To overcome this problem, coat the painted tops with three or four coats of clear floor urethane. Floor urethanes can take enormous amounts of abuse and easily withstand puddles of standing water.

Oil based paints are great for a project like this. They usually cure and harden faster and they have superior adhesion qualities once dry. You can use water based 100 percent acrylic paints, but they would be my second choice. The amount of paint required when using stencils is very little. You might only need 10 or 16 ounces of each color depending upon the size of your counter tops. Craft stores often sell acrylic paints in affordable small squeeze bottles. Custom oil colors may be available at art supply stores.

I need to caution you before you start. This project is going to take you down a one way road. The painting process will be destructive to the plastic laminate surface. But based upon your description of the tops, it sounds like you have nothing to lose and everything to gain.

The plastic laminate tops are superb surfaces to paint. You begin the project by cleaning the tops with soap and water. Remove all traces of dirt, grease and cooking oil. Dry the tops and sand them with a medium grit aluminum oxide sandpaper. Vacuum the dust from the tops and apply your primer coat of paint. Apply the finish coat of paint after the oil primer has completely dried. Allow this second coat to dry. If you are stenciling, now is the time to be creative. Practice stenciling on a painted piece of scrap lumber until you feel comfortable and competent.

Once you have completed your decorative painting and all paints have dried for two days, apply the first coat of clear urethane. Follow the manufacturer's directions with respect to drying times. Sand lightly between coats. To avoid brush strokes in the urethane, thin it slightly. Never exceed the manufacturer's recommendations that are printed on the label.

After you finish this project, you will need to treat the tops with moderate care to preserve the new finish. A cutting board will be mandatory whenever you use a knife and avoid sliding metal cans and other heavy objects across the countertops. Every six months clean the tops, sand them lightly and apply a maintenance coat of clear urethane.

Column 292

Standard window glass must be treated with care when it is cleaned, especially glass exposed to the harsh new construction environment. Glass is actually relatively soft and it is porous. Cement, paint, urethanes, and sealers can penetrate the surface and stick tenaciously to the glass. Sand from brick mortar and stucco, asphalt shingle granules, heavy dust from an assortment of construction activities can all scratch new glass if one is not careful. The best way to avoid scratches on new glass is to protect it with a plastic covering during construction.

Standard window glass must be treated with care when it is cleaned, especially glass exposed to the harsh new construction environment. Glass is actually relatively soft and it is porous. Cement, paint, urethanes, and sealers can penetrate the surface and stick tenaciously to the glass. Sand from brick mortar and stucco, asphalt shingle granules, heavy dust from an assortment of construction activities can all scratch new glass if one is not careful. The best way to avoid scratches on new glass is to protect it with a plastic covering during construction.