DEAR TIM: The removal of an old fan left a large hole that needs to be patched in my stucco home. What type of backer board is used to close up the hole? I assume the stucco just sticks to it and all is well. How does one match the existing texture? I also have many different sized cracks to patch. How do I tackle those? Andy N., Apple Valley, CA

DEAR ANDY: Patching stucco so that you don't see the repaired area is as difficult as patching a hole in a piece of fabric using scrap from the original bolt of cloth. It is virtually impossible to do. A stucco mason can create an infinite amount of textures depending upon the materials used to create the stucco and the tools used to finish it. Blending the new texture with the original is a true art and craft. If you succeed in creating the illusion, go out and immediately purchase a lottery ticket!

To get fantastic results on your job, I urge you to build several small test boards that are slightly smaller than the size of the existing hole. Practice your technique on these. Once you think you have the texture matched, insert the test panel in the hole and step back 20 or 30 feet to view it. Things tend to look different when viewed from a distance. If your existing stucco is painted, paint the test panel as well.

The repair process begins by simply looking at how your existing stucco was installed. Stucco is applied differently in many parts of the nation. In some localities, tar paper is applied over the wall studs and then wire mesh is nailed to the studs. In other areas, wood sheathing is nailed to the studs before the tar paper and mesh is applied. Look at the exposed edge of the hole to see how your stucco was applied.

To make the repaired area waterproof, you need to remove some of the existing stucco to expose the tar paper beneath the stucco. Remove the stucco slowly and carefully so as not to tear the tar paper. The new tar paper needs to slide up behind the tar paper at the top of the opening. One inch of overlap will work, but two inches would be better. The tar paper overlaps the sides and bottom of the existing opening the same distance. This important detail prevents water that may seep behind the stucco from rotting the wood sheathing and structural wood framing.

Galvanized chicken wire or plastering mesh is then nailed over the tar paper. Use galvanized nails that penetrate 1.5 inches into solid wood. The stucco sticks to this wire mesh, not to the tar paper.

The stucco is applied in either two or three coats. Typically a thin scratch coat is applied to the wire mesh. Once dry, this coat stiffens the wire mesh so the weight of subsequent coats does not create waves in the final finish. The thickness of the second coat depends upon the type of final finish you are trying to copy. If the final finish is very rough, then the second coat must stop just short of any indentations that are created when you apply the final coat. Be sure you use a stucco comb to create grooves in the wet second coat. These lines help bond the final coat to the middle layer of stucco.

Try to work in the cooler part of the day if possible. Be sure to wet the edges of the existing stucco before you apply the second and final coat. These edges must also be dust free. Keep the patched area damp to prevent shrinkage cracks. You can mist the repaired area or tape plastic over it to hold in the moisture. Stucco that dries too quickly can crack and never attain full strength.

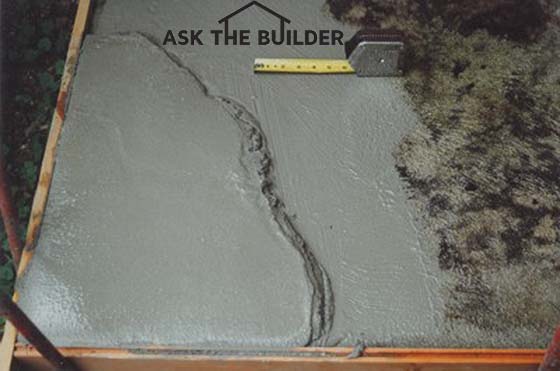

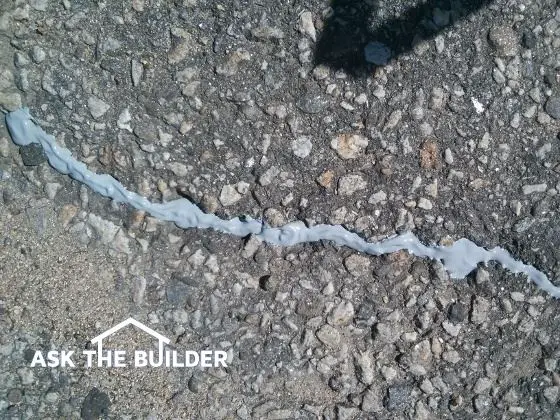

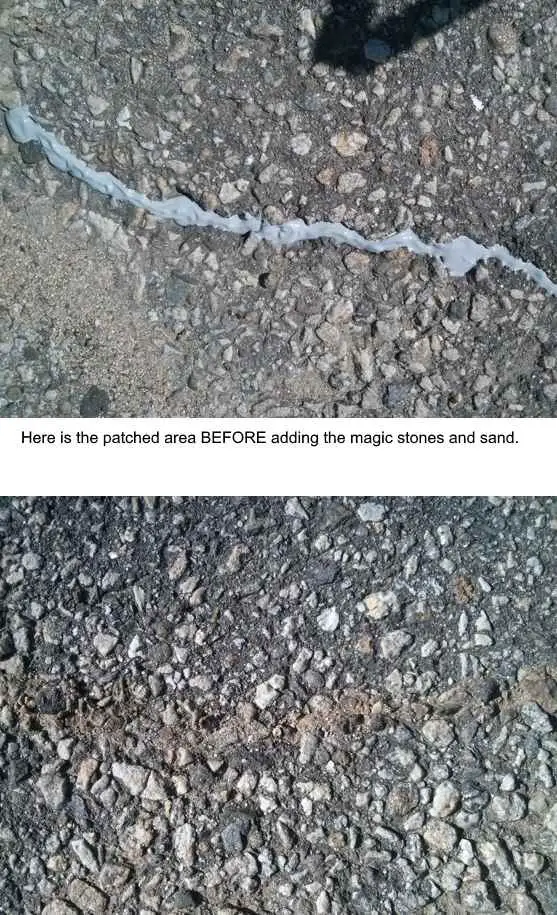

Patching stucco cracks is not too hard, it just requires some patience. Cracks less than an 1/8th inch in width can usually be successfully patched with a high quality siliconized acrylic caulk. Remove all loose debris and dust from the crack. If the crack is deep, apply the caulk at two different times as one thick layer will shrink and cause an unsightly depression. Let the first layer of caulk dry for several days before applying the second coat. Quickly scatter sand that matches the existing finish into the final bead of wet caulk. This will help disguise the crack repair.

Wider cracks can be patched with the cement stucco mixture you created for the hole repair job. These cracks must be undercut for the stucco to hold. Use a grinder or hand-held chisel to make the crack slightly wider at the base than at the surface. This is the same technique dentists use when filling cavities in our teeth. This dovetail design will permanently lock the repair stucco mixture in place.

There is an updated column dealing with Repair Stucco Walls. CLICK HERE to read this column.

Column 423