Embassy Ceiling Suspended Ceiling - Video Series

This is video #1 of a three-part series. Once all videos are complete, they'll appear on this page in addition to their own separate page.

This is video #1 of a three-part series. Once all videos are complete, they'll appear on this page in addition to their own separate page.

Don Kimball, an energetic retired man who loves birds, decided to build an affordable house out in the desert Southwest.

He stumbled across me and asked if I'd help him do his plumbing work.

Here's video #1 in our Plumbing with Serpents video series. Be sure to SUBSCRIBE to Don's channel if you have a YouTube account.

Advance to 5:00 and listen to Don rap while he works. Here's a screenshot of that portion of the next video. I don't think JayZ has anything to worry about.

Installing plumbing drain pipes like this that go beneath a slab can happen in a few days in most situations. Copyright 2025 Tim Carter

New Home Specifications Spreadsheet

New Home Specifications Template With Text

I’ve got two different stories to share with you this week. Are you a homeowner who hires contractors of all types to do work? If so, the first one will resonate with you. Are you a contractor who’s tired of the rat race of bids that never turn into jobs, and do you hate to chase after money for work you performed? You’ll not want to pass over the second story.

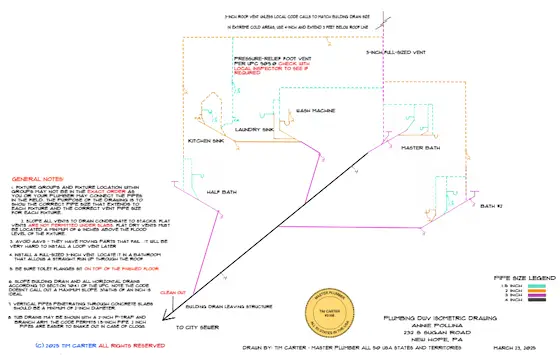

You may like to do crossword puzzles or word games to keep your brain active. I keep my tiny gray cells in tip-top shape by drawing plumbing riser diagrams as well as complex natural gas and propane isometric drawings. I’ve been a master plumber for over four decades. Homeowners, architects, and plumbers hire me each week to do these drawings.

Last week, a middle-aged woman hired me to do her drain, waste, and vent riser diagram, a water-line drawing to ensure all fixtures would get plenty of water, and her natural gas riser diagram. Her local building department requires these to obtain a building permit. Even if the drawings are not required, it’s a good idea to have them done.

This is a small version of a typical drain, waste, and vent (DWV) drawing I produce for homeowners and architects. CLICK HERE to order yours.

I included notes with each drawing when I sent them to her via email. She was very polite and often responded with a few questions. I uncovered a potential problem in her specifications with respect to her water heater. I felt it was too small and suggested she consider installing a tankless heater in her new home.

This nice woman asked me if I’d be kind enough to review a bid she received from a plumber to do the work in her new home. I obliged and was stunned when I studied it. The quote only covered the plumbing drain pipes and water lines that would be under the slab of the house.

It’s essential for you to realize this is just a two-bath house with a small half-bath. The plumber’s quote was for $38,000.00.I almost fell out of my chair. I did a very fast estimate of materials. I felt all the pipes and fittings could be purchased for $2,500. Three thousand dollars of washed gravel would be needed to fill around the pipes. I then estimated it would take two experienced plumbers about four days, at most, to do the work.

Do the math yourself and you’ll see that something is amiss. I emailed the woman and suggested that I create a set of specifications for the plumbing job. The specifications would require the plumbers to break down their bids into labor and materials. They would also have to list the hourly rate a worker is paid in case a change order is requested.

Creating specifications is not that hard for many jobs. You can do it yourself by getting your inspiration from the installation instructions for the products you want installed in your home. Try it. Pick out a specific window, and then go read the installation instructions. You’ll see that all the important steps required to ensure the window will perform well are in the instructions. Don’t assume any contractor is going to always do what’s right. Your contract needs to simply say that the job is going to be done according to the specifications used to bid the work.

I had a conversation with my good friend Wayne the day after my email exchange with the woman. He’s a retired chiropractor. Wayne shared a short story about one of his patients that came in years ago crying. He thought she was in terrible pain, but the tears had to do with her getting ripped off by a contractor.

This woman was very wealthy. More often than not, contractors took advantage of her by overcharging her. She needed a simple screened-in porch built for an upcoming party in just two months. This woman trusted the contractor she hired and gave him a large sum of money up front to purchase materials. You should never ever do this. The only time a deposit like this is required is if it’s for custom materials that can’t be returned.

Calls to the contractor were not being answered. She was in tears because she thought the porch would never get done in time for the party. Wayne had another patient who was a carpenter. The carpenter’s schedule had a big opening in it, and he could use the work.

Wayne told the carpenter to build the porch, but not take advantage of the woman as he would find out. The carpenter got the job, completed it in two weeks, and the woman was happy as a clam.

But it didn’t end there. The woman was so happy, she continued to use the carpenter for all sorts of projects. He continued to treat her fairly. She saw his truck was in disrepair and believe it or not, she purchased him a new one.

The woman found out the carpenter didn’t have any savings plan for his retirement. She helped him start one and she contributed to it with each job he did for her. I know this sounds like a fairy tale, but it’s a true story.

The woman, just like you, wanted to find a reliable trustworthy person, and once she did, she treated him fairly just as you want to be treated fairly by the contractor. It’s the golden rule in reality! Follow it, and magic might happen with all your future jobs.

Column 1605

These 6x6 treated lumber posts need a few more braces before the long double 2x12 beam is set in the L-shaped notches. The optical builders level on the tripod was used to ensure the seat of each notch is at the same elevation. Copyright 2025 Tim Carter

Flowers and vegetables pop up out of the ground in the spring. So, too, deck support posts. You may be a homeowner that desires to create a wonderful outdoor room, or expand that small deck cobbled together by the builder of your home. Allow me to share with you deck construction tips that can save you time, and prevent expensive leaks into your home.

I’ve built more than my fair share of decks in the past forty years. I’ve also inspected many that I’d never set foot on because of the many defects. You can locate videos and articles about deck collapses on the Internet. A friend of my daughter was standing on a deck that collapsed. She broke her neck and ruptured her spleen. She’s lucky to be alive. You don’t want this to happen to you, your loved ones, or visiting guests. A deck construction guide like this can help prevent death or serious injury.

CLICK HERE to get my Deck Construction CHECKLIST!

More Deck Building Tips are Here

Decks that are higher than three feet off the ground can experience significant structural stresses from people dancing during a party. A deck can begin to sway back and forth if it lacks sufficient bracing to prevent the movement. Think about any wobbly table you might have set things on at a picnic or other outdoor gathering. A deck is really nothing more than a giant table with legs.

Decks can detach from houses without warning. There are many causes not the least of which are corroded bolts, wood rot from leaks at the connection point, and inferior construction methods employed by a homeowner with great intentions but little carpentry experience.

The most recent incident of this happened in Pittsburgh, PA. A porch roof on the rear of an older home collapsed. A porch is built just like a deck that's attached to a house. No students died in the mishap, but several received serious injuries that might plague them the rest of their lives.

The first thing you should know about is concentrated loads. The average deck weighs many hundreds of pounds. Some decks weigh tons once you install the decking, furniture, and possibly a hot tub.

Some of this weight will be transferred to your house should you bolt the deck to the house using a ledger board. Think of how approximately half of this weight is bearing on a handful of 1/2-inch bolts! The remainder of the weight might be concentrated on two posts that rest on a concrete pier.

The nails or bolts used to connect the porch roof, which is built just like a deck, couldn't support the weight of the students. The bolts or nails could have sheared off or they could have pulled out of the brick.

The concrete piers must be on solid soil and below the frost line should your deck be located where the ground freezes in the winter. The diameter of the concrete pier should be at least 16 inches. Architects I worked for years ago always specified a two-foot-diameter footing pad in the ground. The concrete pier would connect to this footing and stop about 6 inches above the grade.

It’s not a great idea to bury treated posts in the ground. They can rot or be attacked by insects even though the manufacturer states they’re safe for direct burial. The following two photos show how treated lumber can rot even if it's not buried.

This is a treated lumber post that's been well cared for. I know the homeowner. It's been regularly sealed yet it still rotted out! Copyright 2025 Tim Carter

Simpson Strong-Tie is a USA company that specializes in any number of high-quality connectors made to build decks. The special galvanized post bases, post-to-beam connectors, joist hangers, tie-down anchors, etc. they manufacture will enable you to build a strong deck that lasts. I’d visit their website and immerse yourself in all of their training aids and videos.

Be aware that the fasteners used to connect everything together must be able to withstand the corrosive brew created when rain falls on your deck. The rain leaches copper from the treated lumber. This liquid reacts with exposed bare steel causing it to corrode in short order. You must use fasteners that have a thick coating of zinc to protect the steel from the corrosive brew.

I feel the best decks are ones that are similar to a real table you have inside your home. The average table has four legs and is very stable. Imagine creating a deck that sits just two inches from the face of your home. There are no holes drilled into your siding or brick. Leaks into your home are eliminated.

Don’t discount the use of steel tubing in place of treated lumber posts. The first big deck I built over forty years ago employed 4-inch-square steel tubes. A local welder added a 10-inch-square plate at the base. It had a drainage hole in the center and four 9/16-inch diameter holes at the four corners. I used anchor bolts to connect the post to the concrete pier.

The top of the steel post had two plates welded to it creating a U-shaped notch that surrounded the horizontal wood deck beam. The steel posts were primed and finished painted before we built the deck. I visited this deck not too long ago and the steel looked as good as the day I installed it.

Column 1604

Building product defects - The sand and small rocks used to be solid concrete blocks. They failed because of a manufacturing defect. The mortar used to lay them didn’t fail. Copyright 2025 Tim Carter

Building product defects can sap money and energy from you. Building materials made in factories can contain latent defects. These are hidden time bombs that can explode causing mayhem in your life. It’s not easy to spot them, but there are some things you can do to prevent both physical and financial harm. I’ve dodged the bullet several times in my career and lifetime.

Several decades ago I built a stunning Queen Anne Victorian replica home for my family. I purchased top-quality windows made by a major brand. These windows looked exactly like ones you’d see in a home built in the late 1800s including the distinctive extended window-sill horns that the exterior trim rested upon.

About ten years after they were installed, I was reading the latest issue of the Journal of Light Construction. I subscribed to several building magazines to help stay abreast of the latest products and building techniques.

There was a very tiny announcement about the major window brand filing a huge lawsuit against a national paint company. The lawsuit alleged that the paint company supplied the window manufacturer with a defective clear wood preservative. The window company used this preservative to prevent wood rot in both the window frames and the sashes.

My windows contained this invisible defective preservative. The window company sent out one of their engineers to confirm this. Wood rot was discovered in all of my windows. The window company supplied me with new windows and a cash settlement to install them. I was also reimbursed for all the required exterior and interior painting. To say the least, I was very lucky. Without this settlement, it would have cost well over $50,000 to replace the rotting windows.

These are the new replacement windows I had to install after the original ones rotted out. Copyright 2025 Tim Carter

Not too long ago I met a friend at a restaurant here in New Hampshire. A concrete block wall separated the parking lot from an outdoor patio. The top courses of the concrete block had disintegrated, and were nothing more than sand and small stones. There was not enough cement in the block to resist the freeze/thaw cycles experienced each winter.

The lack of cement in the block could have happened because of a malfunction in the batching machinery that measures out the quantities of sand, small stones, and cement. It’s also possible there could have been enough cement, but the dry mixing process didn’t distribute it evenly. Finally, too much water might have been added to the mix. The failure could have been one, or several, of these possibilities.

My most recent encounter with defective materials happened on my own outdoor deck. Several years ago I installed a composite decking and railing system made by one of the top deck manufacturers. I took great care to install the materials following the manufacturer’s instructions. I even had their local factory rep stop by to offer up suggestions before I started the work.

The round aluminum balusters in the railing were held in place by plastic extrusions that fit into the top and bottom fiberglass railing members. The day I installed them they fit perfectly with no gaps where the extrusions touched the vertical railing posts.

Two years later I was out on the deck one day and noticed a 1/4-inch gap between the end of one of the extrusions and a post. I then took the time to look at all of them. Much to my surprise, there were huge gaps everywhere. The 8-foot-long extrusions were now 3/4-inch shorter than when I installed them. It was a summer day, and if anything, the extrusions should have been longer as the plastic has a significant expansion coefficient.

The flat plastic extrusion that has holes for the round balusters used to touch the deck post. Look at the 3/4-inch gap! Photo credit: Tim Carter Copyright 2025

I reached out to the manufacturer. They admitted they had a manufacturing defect that caused the extrusions to stretch as they inched their way out of the molding die. After a few years, the plastic shrinks back to what it should be. That’s not a good thing for folks like you and me!

The manufacturer sent me all new extrusions to replace the defective ones. I decided to wait a year or so before installing them just in case they decided to shrink in the box!

What can you do to prevent situations like I’ve experienced? When it comes to buying wood windows, it’s not easy. Most come primed from the factory. A builder will almost never invest the time to paint the windows with finish paint before they’re installed. It’s an enormous amount of work, but you can remove the plastic jamb liners and paint all exposed surfaces of the entire window frame. You can caulk any hidden joints where water might soak into the end grain of the wood.

Instead of using concrete blocks made in a factory, consider using natural stone made by Mother Nature. She’s been doing it so long that she’s perfected making building materials that can last millions of years. Granite, sandstone, and limestone can last for many thousands of years in the harshest climates.

As for plastic deck railing components, I’m not sure there’s an easy answer. I would defer to railings you might find in older homes such as wrought iron. Invest in time-tested materials where you know the cost to replace something is both difficult and time-consuming.

Column 1603

This wood fence post was created using several simple saws and some patience. Copyright 2025 Tim Carter ALL RIGHTS RESERVED

Wood is such a magnificent building material in my opinion. It’s strong, it’s beautiful, it’s easy to cut and shape, and it can be used to create delicious eye candy both inside and outside your home.

My lovely wife enjoys outdoor gardening. She inherited this love and skill from her mother. My family was the exact opposite. I grew up in a tiny house on a small urban lot that sported grass and two oversized evergreen bushes next to our front porch.

One day my wife handed me a gardening magazine that had just arrived in the mail. In it was a color photograph of a decorative wood fence that had a unique decorative fence post. “Do you think you can recreate this for me along our west property line? This decorative fence will provide an excellent backdrop for my garden plants. The plants will stand out much like artwork does on a painted wall.”

There were no dimensions in the photo or the article. I knew the fence would make her happy and I accepted the challenge. I was attracted to the decorative posts in the photograph. I knew I could create them using my hand-held circular saw. CLICK HERE to read more about this special fence. Here's a photo of that fence I built for my wife with the fancy post:

This 4-foot-tall fence post is as straight as the day it was installed. It was not set in concrete. © 2025 Tim Carter

That project activated my decorative fence-post radar. Each time I saw a wood fence, I began to take mental photographs of any unique posts or fence panels I saw. They could be found at the most unusual places. The city zoo, public gardens, private gardens opened for tours, state parks, and garden centers.

Realize this was before the Internet. You are so blessed to be able to see thousands of photographs of wood fence posts using image searches and on websites dedicated to outdoor home design.

Several months ago I visited a large public garden in southern California. While immersing myself in the thousands of stunning plants and trees, I found myself walking on a wood-plank pathway. It was bordered by a simple wood fence with stunning 6x6 decorative wood posts.

While admiring the workmanship, I thought, “Just about any homeowner could replicate these posts.” The first thing to do is practice. That starts by purchasing one 8-foot-long 4x4 at a home center or lumber yard. This one piece of timber will yield eight practice fence post tops.

As you study photographs of decorative posts, note how the geometry of the cuts is often created using simple 45 or 30-degree angles. Common circular saws can be set to create these angles. Should you have access to a table saw, you can achieve the same results.

I suggest you cut the 8-foot 4x4 into four two-foot-long pieces. You can now fashion 8 different fence post designs if you want. The decorative posts I cut for my wife all those years ago were created by making twenty saw cuts at the top of each post. I was able to complete all the cuts in about ten minutes.

I spent just five minutes drawing the lines on the wood that I’d follow with the saw blade. You’ll discover you can master simple and precise cuts with just an hour’s practice.

Once you’ve achieved the confidence to create the posts you want, it’s time to select the best timber. Redwood and cedar contain natural preservatives that can resist rot and insect infestation. Both species have helpful associations that promote the best use of the timber. Reach out to them to see their best advice for how to install fence posts that can last decades.

Locust is also a fantastic species for wood fence posts. Midwestern farmers have used locust fence posts with great success. These are hard to find, but if you can locate them, give them a very serious look.

Should you decide to use treated lumber, I urge you to take your time when selecting the post material. Look at the ends of the timbers and choose ones where you can see the center of the tree when it was a seedling. These posts will resist warping and twisting. Purchase treated lumber rated for burial in the ground. This lumber contains more of the copper preservative to resist rot and decay.

I recommend you stain or paint all the wood posts before you install them. Water in the soil is your enemy. You want to prevent water from entering the wood.

I’ve had the best luck setting fence posts in crushed gravel. I’m not a fan of using concrete. Should you have to remove a fence post in the future, concrete can make it an arduous task. Crushed gravel compacts like concrete and is easier to chip away.

Fence posts that only poke out of the ground four feet or less often don’t need gravel placed around the posts. You can compact soil around the posts, and the fences will stand straight for many years.

Column 1602

The total distance between the floor joists above and the finished ceiling surface is just 1 and 3/4 inches. Wow! Copyright 2025 Tim Carter

I’ve shared in a few past columns the wonderful time I’ve been having with my son. Each weekend I get to spend hours of quality time with him while we work on finishing his basement.

I’m fanatical about having access to wires, pipes, ducts, etc. that you often find in a basement ceiling. You achieve this with a suspended ceiling like you might see in an office building or your dentist’s office. My previous dentist installed colored translucent panels of wonderful nature scenes right above the chair. They helped to produce a calming effect if you didn’t like dentists drilling on your teeth.

My son didn’t want the standard plain vanilla suspended ceiling. He went hunting using the image search tool you’ll find in most search engines. Within seconds he zeroed in on a system I had never seen before.

This ingenious company decided to recreate the coffered ceiling look but compress it, keeping enough relief to provide a very interesting appearance.

We visited the company’s website and watched their installation video. I was sold within seconds. Not only was I enamored with the ease of installation, but I also loved the fact this system hugged the existing floor joists. The distance from the bottom of the floor joists to the ceiling surface you touch and see was as small as 1 and 3/4 inches!

The system consists of just five parts:

CLICK HERE to watch a short video showing the above components.

CLICK HERE to watch this video.

The anchors and rails work like a french cleat. Each anchor has a channel with two upward-bent grooves. The rails have two rows of parallel fins that slide into the grooves of the anchor. The extra fins on the rails allow you to do minor height adjustments should your floor joists not be in the same plane.

The anchors are screwed to the floor joists above. The rails slide into a dovetail groove in the main crossbars. You must get the main crossbars straight and they have to be parallel. The error tolerance is less than 1/16 inch so take your time. While it seems intimidating, it’s not. Once we got the hang of it, we were having a blast. It’s like working with a wonderful adult Lego toy!

The first step in the installation process is to determine the layout of the large 2x2-foot panels. You want to center them in the room and you want large cut pieces against all the walls. The best way to do this without doing complex math is to just lay out the tiles on the floor creating a 2-inch space between each one. You have only two ways to install them as you’ll discover.

Your layout decision determines the location of your first row of anchors. My son and I chalked a crisp line parallel with the primary wall in each room. We measured the width of an anchor and divided it by 2. This gave us a point where the edge of each anchor should be on the floor joist above. The anchors must be installed in a straight line. I discovered the extra minutes to do this paid off in spades later.

The main crossbars are all parallel and must be spaced with great precision. The company thought of this too. They include with each box of crossbars a spacing template. Notches in the template allow you to space the anchors exactly where they should be. I used the template to get the position of the first and last anchor of each row. I’d then chalk a new crisp line to space the rest.

There’s little to no waste with this system. Cut pieces of main crossbars are used to start the next row. The same goes for secondary crossbars. Any small pieces left over from cuts can be used to make other small crossbars.

We used a new 6-inch hole saw to cut the circles for low-profile LED recessed lights. It was simple to do. It’s best to have the saw spin slow as you make the cut.

I’m quite sure you want to know the name of this system so you don’t have to guess. I didn’t mean to tease you on purpose. The name is Embassy Ceilings. I can tell you the system is such high quality it could be installed in an embassy building in a foreign capital! Within a month I’ll have a detailed installation video ready for you at my www.AsktheBuilder.com website.

Column 1601

I received two frantic phone calls in less than twelve hours several days ago. Both calls were about plumbing emergencies. The one young woman was so flustered she hung up on me the instant she discovered my Google Maps listing was about drawing plumbing plans, not doing plumbing service calls. I speculated a pipe had burst and water was flooding her home once the line went dead.

The second call was from the young woman who attends my church. I’ve shared other tales about her home-repair challenges in past columns. This time the hot water in her home would only last for ten seconds. Ice-cold water would then flow from the faucets and her sole shower head. The last thing anyone wants in New Hampshire is to take a cold shower in February.

I asked her to send me a photo of her boiler room so I could start to diagnose the issue without a house call. I saw a pesky mixing valve in the photo. These valves blend cold water with the scalding hot water produced by the boiler. Without one, your skin would look like that of a lobster in a cooking pot. Second-degree burns would follow in minutes. Mixing valves malfunction if they’re not exercised on a regular basis.

The young woman admitted she was pretty much clueless as to how all the plumbing worked in her home. I shared that the fix was easy and she breathed a sigh of relief. She thought she might need a new boiler.

Once the emergency was over, I pondered how these two calls could save millions of dollars should you, and every other reader of this column, get up to speed on how to prevent expensive plumbing service calls. A plumbing service call can start at $300, and be as high as $800.

It’s important to realize I’ve been a master plumber since age 29. The first place to start is your incoming water supply line. The water pressure inside your home is almost always greater than 40 pounds per square inch. Should a water line rupture, hundreds of gallons of water can flood your home in minutes. It’s imperative you know how to shut off the main water valve to stop the flow of water and that the valve works.

The biggest mistake most homeowners make is the failure to exercise valves. Exercising valves means to turn them on and off. You exercise your faucet and toilet valves each day by using the fixtures in your home. This is why those valves turn on and off with ease.

You need to do the same thing with shutoff valves. Set a calendar reminder on your phone to turn on and off your main shutoff valve once every three months. The pesky ones are old-fashioned gate valves that have a circular handle. The best shutoff valves in my opinion are ball valves. These have a straight handle. You just rotate the handle 90 degrees to get it to open or close.

When was the last time you tried to turn off and back on a shut-off valve like this or the one under your toilet? Copyright 2025 Tim Carter

It’s not a bad idea to exercise all shutoff valves under sinks and toilets, but that can be a pain in the you-know-what. Shutting off all the water in your home using the main valve will stop the flow until such time as the repair can be made.

Tool rental businesses allow you to make emergency repairs that will save you hundreds of dollars. You can repair burst copper water lines using a press tool that makes water-tight connections using special copper fittings that have internal rubber o-rings. I checked moments ago and these tools can be rented for $50 for an entire day. I have a video on my AsktheBuilder.com website showing how to use a press tool.

Simple hand tools can also be used by you to make repairs to PEX and CPVC water lines. Watch a few videos on YouTube.com and consider purchasing these tools to have on hand.

Drain lines are not as important as water lines in my opinion. Leaks in drain lines can be stopped by not using the fixture. Clogs are perhaps the biggest issue with drain lines. Hundreds of millions of dollars are given to drain-cleaning companies and plumbers each year by homeowners like you. Much of this can be prevented.

For starters, only flush bodily waste and toilet paper down toilets. Avoid flushing feminine hygiene products and the dreaded flushable wipes. I recorded a very popular video that you can watch on my website to see what happens when you flush wipes. It’s okay to use wipes, but dispose of them in a sanitary waste can in your bathroom just as you’d get rid of a soiled infant diaper.

Grease is a huge issue. You can prevent grease clogs by wiping all liquid grease from dishes and cooking pots and pans before washing them. I save not-so-dirty paper towels and use these to sop up grease. I then throw away the paper towels in the trash.

Grease buildup in drain pipes is expensive to remove. Plumbers need to flush the drains with enormous amounts of very hot water. It’s an expensive service call.

I pour 25 gallons of boiling water down my kitchen sink every three months to ensure my pipes have no grease buildup. You might try doing the same thing.

Column 1600

This medallion was created using simple rounded stones, cement stucco, and an artistic flair. Imagine what’s possible on your patio, driveway, or garden pathway! Copyright 2025 Tim Carter

Last fall I traveled with my wife across the USA. We arrived in Los Angeles, CA and a few hours later got to hold our newest granddaughter. It was magical to say the very least.

My youngest daughter inherited her mother’s love of gardening. It was decided a day trip to the magnificent Huntington Botanical Gardens located in San Marino, CA was in order. The adventure was the highlight of the trip. I can’t begin to share with you the tranquility that washes over you when you meander through paths surrounded by countless plants of all types and sizes.

Our circuitous route led us through the Japanese Garden. I was attracted to a large. paved patio at the Freshwater Pavilion. Beneath my feet were hundreds of thousands of small rounded stones. Skilled workers created a mosaic pattern carefully orienting the oblong colored stones. These stones were set in cement stucco that bonded them to a large concrete slab.

I blinked my eyes and was taken back over forty-five years. Our kids weren’t yet a glint in my or my wife’s eyes. My bride of just a few years asked me to build her a goldfish and lily pond in the backyard of our second home.

I was filled to the brim with energy as my 30th natal anniversary was years away. I’d come home from work and then work until dark doing all that was necessary to create the pond.

We were fortunate to have enough fall on the lot allowing me to install a drain in the pond. This would make cleaning it a simple chore. My wife asked me to create a kidney-shaped water feature. Steel-reinforced concrete would be the perfect material.

My wife showed me a magazine photograph of a garden path that was created using small colored stones set in mortar. I knew I could reproduce that look.

I hand-mixed the concrete making it quite stiff. I was able to shape it with no problem. It helped to work in the cool of the evening.

I visited a local masonry supply business that sold sand and gravel. They had an assortment of colored, rounded glacial gravel that would be perfect. I purchased a small sample and my dear wife approved them. Many were the size of normal green or red grapes.

Bonding these small stones to the concrete was easy. I mixed medium sand and Portland cement. My mix was 3 measures of sand to 1.5 measures of Portland cement. I added enough water to make stucco the consistency of applesauce.

I’d only mix up enough stucco to last me one hour. Before I applied it to the concrete, I spritzed the dry concrete with water. Years later I discovered that it would have been even better to apply a thin coat of cement paint to the concrete just before applying the stucco. Cement paint is made by mixing Portland cement with clear water until it’s like a thin paint.

CLICK HERE to see cement paint being installed to bond new concrete to old concrete.

I would trowel on a 3/4-inch-thick layer of the cement stucco to an area about 1-foot square. My wife would hand me the stones and tell me where to position them. We were a great team and she made sure the colors were random. My only regret is I never took photos of the process or the finished job.

What can you do at your home to add some color and texture in your outdoor paving? You are so much luckier than I was. I had one photo as a guide. You have countless photos on the Internet. You can search design websites or use any search engine’s image search to help you find what you like.

You’ve also got amazon.com or local landscaping businesses that often stock lots of different colored gravel. You can purchase bags and boxes of colored glass beads to set in stucco. Some are crystals that will glitter in the sunlight.

Imagine covering 1-foot square concrete pavers from a big box store with colored stones, glass beads, or even weather-resistant ceramic tile. These finished blocks can be set into a new concrete patio or sidewalk. You can use them as simple stepping stones in a miniature garden.

Your possibilities are endless. Spend several hours scouring the Internet for inspiration. Visit local public gardens to see if they have paving like what I saw in California. The time you spend getting the exact look that dazzles you will pay off in spades.

Column 1599

This is a custom hand-painted tile backsplash. The owner had a local artist paint the white tile with durable oil-based paint. Copyright 2025 Tim Carter

Two days ago I was skim coating hundreds of square feet of new drywall in my son’s basement. I added water to the thick drywall joint compound so it was the consistency of latex paint. Investing in this extra step makes the new drywall satin smooth because the paper face of the drywall ends up with the same texture and porosity of the taped joists and filled screw heads.

I thought about how the walls in his basement could come alive in any number of ways. Many people hang paintings or posters to break up the monotony of a painted wall. That works, but framed artwork can put a serious ding in your budget.

As the day wore on and my shoulder started to ache, I thought about what I did when I was a little younger than my son. My lovely wife and I purchased a three-story five-bedroom home that needed lots of tender loving care. We painted the entire house inside and out.

My wife loved wallpaper. I installed a pattern that was from the famous Williamsburg Colonial collection in our entrance hall and the stairs leading to the second floor. Many visitors and friends complimented us on the choice.

The plain walls in the dining room were transformed by installing a simple chair rail moulding. The room already had a large crown moulding where the walls met the ceiling. I painted the walls below the new chair rail and installed a different wallpaper above the moulding. Once again, plain walls became eye candy.

The third floor of this grand house had two bedrooms. I staked a claim in one of them making it my man cave. The room had a sloped wall created by the roof rafters. Many Cape Cod houses built after World War II have this feature.

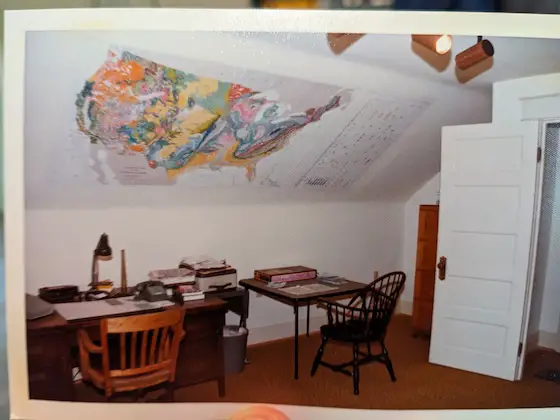

Geology was my college major. In addition, I had always loved maps of any type. I remembered a huge 5-foot-tall by 10-feet-long color geologic map of the USA that adorned a wall in one of my classrooms. I ordered the same map by mail from the US Geological Survey. There was no such thing as online ordering back in the 1970s.

With great care and help from my wife, we glued this map to one of the sloped walls in my office. This simple two-hour project brought a smile each time I entered the room. The range of colors in the map, as well as the symbols and legend, added a wow factor to anyone that visited. It was dramatic to say the least.

Here's the actual map in my office. I can't believe I found this old photo that's almost 50 years old! The photo was probably shot in 1977.

We customized our kitchen with the help of my wife’s younger sister. She had an artistic flair, and volunteered to hand-paint some yellow flowers on blank white 4x4 tiles we used for the countertop backsplash. She used the same oil-based paint I applied to the interior doors and trim in the house. That paint was durable and could withstand being washed.

All of the things I’ve just described can be done by you in your home. The possibilities are endless. I spent a few hours online and was amazed at how easy it is to make your home something that is unlike anything else in the world.

For starters, there are websites that will take your favorite high-resolution photographs and transform them into wallpaper. You can control the size of the scene on the wall. Imagine that amazing sunrise or sunset photo you took on vacation! You can relive it every day in your home on a particular wall.

You can do the same thing with ceramic tile. Companies have tile murals ready to purchase or you can create your own by uploading a high-resolution photo you have. You get to select the tile size and the finished size of the mural.

My son-in-law purchased a condominium this past summer. The previous owners hired a local artist to paint a lighthouse sitting on a rocky Maine shoreline. This painting was done on the wall behind the kitchen sink. The artist signed her work in the lower right corner for that personal touch. The vibrant colors bathe the kitchen in tranquility. You can almost hear the waves crashing against the rocks!

Your takeaway should be just one thing. Think about how much time you spend inside your home. Wouldn’t you be in a better mood if the walls, and even the ceiling, had on them scenes or images of the things that bring you the most happiness?

One easy way to do this is to mimic what’s in my dentist office. The husband-wife team love the outdoors. A large flat-screen television is in the waiting room. They have a series of photos they took on vacations that appear on the screen. Each photo is there for about ten seconds then the next one appears. This might be a simple way for you to make one, or more, of your rooms to be yours and yours alone.

Column 1598

Subscribe to the FREE Ask the Builder newsletter to receive professional advice for your home. Complete the form below and each week you'll get:

Unsubscribe at any time. We respect your email privacy.