Residential Steel Beams

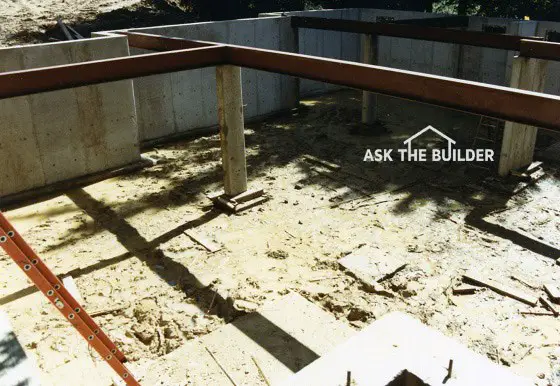

Residential steel beam - There are quite a few in a home I built in Amberley Village, Ohio. The beams are 10 inches tall and weigh 31 pounds per linear foot. You can span up to 14 feet with these! © 2018 Tim Carter

A residential steel beam is very common in most homes. Most are 8 inches tall, but 10 or 12-inch-high beams allow you to span greater distances with fewer pesky columns.

Revised February 2018

Residential Steel Beam TIPS

- Beams come in all sizes, thicknesses, weights, lengths and galvanized

- Steel columns supporting beams should be welded and the columns filled with sand

- Watch VIDEOS below about beams & columns!

- Taller beams allow you to put columns farther apart

- Structural engineers or architects must size beams

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter

DEAR TIM: My house plan calls for steel beams that will support the floor joists and even parts of a brick wall. Can I substitute wood beams for steel? Is a steel I beam hard to handle on the jobsite?

Do you think I can install one with some friends? How can you get the best steel beam prices as my budget is pretty tight? If I find a used steel beam, do you see any problems incorporating that into my new home? Steve B., Cinnaminson, NJ

Related Links

Column & Beam Construction - Use Steel and Wood

Beam Installation Basics - Be Careful!

DEAR STEVE: Steel I beams are pretty husky structural components used sparingly on a residential building site, because wood is the primary structural material found in most homes.

However, steel is a ho-hum material on a commercial or industrial construction project as it’s the mainstay of these larger projects where wood is scorned because of its inherent fire danger and limited characteristics as buildings get big.

Residential Steel Beam Video - Exposed Beams For Modern Look

This video has lots of great photos of steel beams used in homes. You may get inspiration from watching this. It's worth it.

CLICK HERE to get FREE & FAST BIDS from local structural engineers in your city or town.

Architects and engineers employ steel beam design in homes for both beams and columns because it’s so strong. You can typically hold up the same loads with wood, but you need more of it and usually the size of a wood beam is much larger than a steel I beam, that’s holding up the same amount of weight.

Termites and other wood-destroying insects don’t eat steel, so that’s a distinct advantage if you want certain parts of your home to remain standing.

You can substitute, in many cases, a wood beam for a structural steel beam. If you desire to do this, be sure you have a structural engineer, or an architect, specify the material and the needed supports.

If you do use steel, pay close attention to the connection details at the steel beam support. The connections between the beam and columns must be secure.

Steel is Heavy - Human Crane Lifts Kitchen Steel Beam Video

Watch this video to see how many men can lift a steel beam. Better have people you can TRUST doing this!

Don't rely on simple thin straps on top of columns that bend over the bottom flange of the beam. These tabs are just temporary measures until a welder shows up.

Do NOT Put Masonry On A Wood Beam

I would never install masonry on a wood beam. There's too great a chance the wood will deflect and cause failures in the masonry. What’s more, it may be a building-code violation in your area.

Steel beams, as you might suspect, are heavy. Steel beam dimensions and sizes are not the same. You can have two different beams that are nearly identical in height and length, but one may weigh twice as much as the other beam.

Typically, you’ll see beam sizes called out in numeric form like 8x17. Usually this means the steel beam is very close to 8 inches tall and weighs 17 pounds per linear foot. This is a very common size found in many residential homes. But you can get 8-inch-tall steel I-beams that weigh over 35 pounds per foot. I installed 10x31 beams in the last house I built for myself.

Two Men Setting a Residential Steel Beam

Watch these two corn-fed men put a steel beam in place in less than two minutes! WOW!

CLICK HERE to get FREE & FAST BIDS from local structural engineers in your city or town.

Taller Beams are Better

The issue with the typical 8x17 steel beams you find in many homes is they require support columns about every 8 feet on average. If you go to finish a basement, these columns are problematic.

You can avoid lots of columns by installing a taller beam. The taller the beam, say 10 or 12 inches rather than 8 inches, the greater the distance you can span between support posts. I had spans as great as 14 feet in my own basement using the 10x31 steel beams.

Heavier beams can sometimes span greater distances between posts. An 8x35 steel beam can carry more weight than an 8x17. A structural engineer or savvy architect can refer to his steel-beam guide and determine all of this for you.

CLICK HERE to get FREE & FAST BIDS from local STEEL-BEAM fabricators!

Rust Prevention for a Residential Steel Beam - Galvanize or Paint

If you're going to be using steel in a wet area and are worried about rust, you can order them hot-dipped galvanized. I worked with galvanized beams and columns for a job I did at an orphanage in Jamaica. The cost is higher, but if you need that rust protection, realize it's available.

If you can't afford galvanizing, then prime and finish paint the steel beams and columns before you install them. Put on three coats of paint for the best protection and use a special rust-preventative paint made for steel.

Here's a spray paint that's great for steel beams and columns. It contains a metal primer. This brand also is available in quart or gallon cans if you have LOTS of steel to paint. CLICK THE IMAGE TO ORDER IT NOW.

But take a moment and do the math. Let’s say you have a ranch home and a 40-foot-long 8x17 beam is called for in the plans. You can have that beam delivered to your building site.

Don’t try lifting it yourself, as it weighs almost 700 pounds. A smaller beam that long presents handling challenges as well because it will be like a wet piece of spaghetti when you pick it up with all your friends. If you’ve never handled beams before, it’s best to work with smaller ones before trying to handle long pieces of steel.

Steel Is Cheap - Well Worth The Investment

Steel is a commodity, and its price fluctuates. The current steel beam price you have to pay for new steel may not be bad as you might think. Currently, the market is depressed and supply may be far greater than demand. You may be pleasantly surprised to discover that you can purchase a construction steel beam for not much money.

You may be able to find decent steel beams from a demolition contractor who routinely salvages them from buildings. They sell them for scrap, so the price you pay will usually be much less than that of a new beam. However, you have all sorts of challenges when dealing with used beams. You might not get the exact size you need, the beams can be bent and you have to figure out how to transport it to your job site. My guess is a demolition contractor is not set up to do this for you. But stranger things have happened.

At the end of the day when you compare all the costs involved in obtaining a used beam instead of a new one, you may discover there’s not that much of a difference in price. In any event, be sure the beams you use are primed and painted to prevent or minimize rust. Scroll up to get the best paint.

Steel Columns

I'd never use wood to support a steel column. It's best to use steel. Round steel columns are the universal standard in residential construction. The issue is in a fire, the steel columns can soften and the beam can collapse.

You can avoid steel columns from bending and failing in a fire by filling them with dry sand. Just order the steel column with a 1/2-inch hole drilled about two inches down from the top. Use a plastic tube and a funnel to pour the sand into the column.

Be sure you have a welder weld the steel column to the underside of the beam for the best connection. You can also have the steel fabricators drill holes in the bottom of the beam flange and bolt the column to the beam. You'll have to price out each option to see what's the most economical in your area.

If you decide to try to erect the steel yourself on a job site, be very aware of the dangers. The pockets in a poured concrete foundation are not that deep and if you’re not careful the beam can slide out of one end while you’re futzing with the other end of the beam.

To level beams in pockets you need solid-steel shims of different thicknesses. Never use wood shims, even treated lumber that is not supposed to rot. The heavy loads on the beam can compress the wood over time.

Steel beams can be blown over by wind if they are not secured. I’ve seen beams collapse after a rainstorm saturated clay soil causing it to expand and lift up columns that are supporting the beams. Hundreds of pounds of weight floating above your head and body on a construction site are never to be underestimated.

The size of steel beams and the size and spacing of the steel columns that support the beams needs to be done by a trained and educated professional. You can't guess and hope the beams and columns will work. Hire a structural engineer or an architect that has deep experience in sizing beams and columns when you decide to install or modify any you might be working with in your home.

Author's Notes

I received the following email from James Calhoun, who is an Architect. He wrote:

"Tim, something you might want to know. Most municipality building codes do now allow used structural elements, like old steel beams, to be placed into new constructions without certifications by an Architect or Engineer (who in their right mind would do that...) or a serious (50%) devaluation of the rated structural capability of the member. Otherwise, you did a good piece on the advantages of steel in residential structures. I design steel for homes all the time."

Thanks, James.

CLICK HERE to get FREE & FAST BIDS from local structural engineers in your city or town.

Jason could have benefited from this column. Read the August 18, 2019 Newsletter to see dramatic photos of Jason's problems.

Column 818

34 Responses to Residential Steel Beams