How to Build on Great Soil | The DIYr that dug this footing made several serious mistakes. The biggest one is they didn’t remove all the topsoil and organic material from the center of the building site. Copyright 2023 Tim Carter

Building on Solid Soil - Get a Free Soil Map

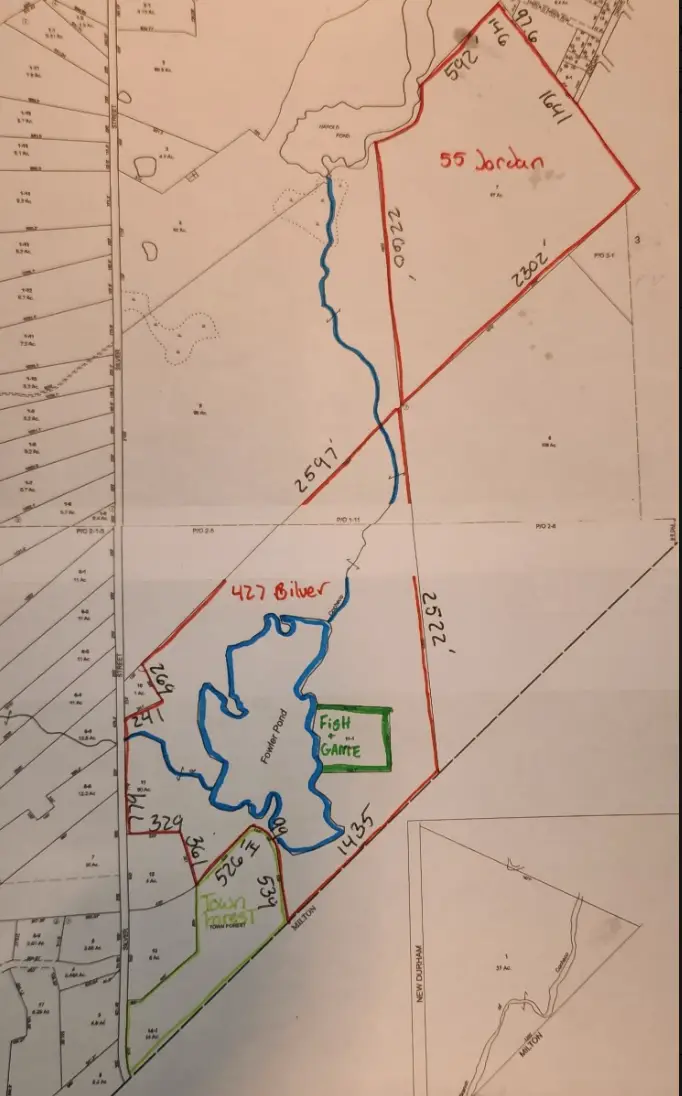

My college degree is in geology. At the time I was in school, I had no idea how valuable this knowledge would be once I became a full-time builder. There’s a very good chance I was the only builder in Cincinnati, Ohio that knew soil maps existed and how to interpret them. Watch this video about soil maps.

Cincinnati has a little-known reputation for having the highest per capita amount of houses damaged by landslides. California gets all the ink and headlines in the news when their winter storms cause dramatic images of houses falling into the ocean but Cincinnati is plagued by slow-moving landslides that affect thousands of parcels of land.

A few decades ago, the most expensive retaining wall ever built was completed in Cincinnati at the base of Mt. Adams. I’m not sure this record still stands, but it’s all because of poor soil conditions on many of Cincinnati’s hillsides. I was exposed to this reality while in college and I’ve never forgotten it. You can read a magazine article steeped in political and racial bias about the history of this massive retaining wall here.

This is an aerial photo of the massive retaining wall at the base of Mt. Adams in Cincinnati. huge steel cables penetrate into the bedrock and are anchored inside a tunnel deep within the earth. Photo credit: Cincinnati Enquirer - Fair Use Doctrine usage

This is a great close-up shot of the massive retaining wall showing the huge concrete piers that penetrate deep into the colluvium at the base of Mt. Adams. Copyright Bill Griffin Photography - Fair Use Doctrine - CLICK HERE for Bill's Instagram page.

Your house has an intimate relationship with the ground. They constantly touch one another. The same is true for any structure built anywhere on the planet that doesn’t float on water. The foundations of all buildings connect to the earth. The ground must be able to support the weight of the building. If it doesn’t, the house will shift later causing all sorts of expensive structural issues such as cracked foundation walls, doors and windows that don’t fit right, and tilted floors.

Years ago I became friends with an intellectual property attorney. He and his wife purchased a lot from a large tract builder. The builder then proceeded to build a large home for my friend. A few years later the attorney called me to come over and look at some disturbing things inside the home. The center of his basement floor had a disturbing huge hump in it. The center I-beam that ran the length of the house was twisted and the 2x4 plate on top of it was only 7/8ths of an inch thick due to being compressed.

A massive crack extended from the foundation up to the roof. It turns out this building lot used to be a deep ravine. The subcontractor who did all the cut-and-fill groundwork made a massive mistake by bulldozing trees and brush into the ravine and then proceeded to cover it up with dirt. My friend’s house was sinking into the ground as the dirt filtered down and filled all the voids around the trees.

When the hole was dug for his foundation, the ground looked fine as the fill had been compacted at the time. You could have only discovered the hidden time bomb had you looked at a topographic map of what the land looked like before the developer purchased it. This map would have shown the ravine that was filled in. Even so, all could have been fine had no organic material been covered over in the ravine. You would have only known this if you would have paid for a geotechnical engineer to come out and do a core sampling of the soil.

Several months ago a visitor to my www.AsktheBuilder.com website asked for advice about pouring footings for a new house he was building. He had purchased a lot that had lots of mature trees on it. He cleared many trees to get ready to build but he failed to remove all of the topsoil that would be under the house.

The photos he sent were deeply disturbing. He had dug the trenches for the footing and got down to the B horizon in the soil where there was no organic material. However, at one corner of the house, he had not dug deep enough and was about to pour the concrete footing on topsoil.

The center of the excavation still had all sorts of topsoil and tree roots in it. He was going to pour the concrete slab on top of this mess! I pointed out all the mistakes I saw and we parted ways. I have no idea if he corrected the mistakes. If not, he’ll pay dearly down the road.

You don’t have to be a geologist to understand a soil map. Almost all counties in the USA have been mapped and you can now obtain these invaluable building aids online for free. You’ll be able to locate your lot on the map with little effort. Once you do this, you can then see what soil is present. The map then tells you all the characteristics of the soil and how suitable it is for building.

Never build anything on topsoil. It contains organic material that can rot and it’s not capable of supporting concentrated loads. Never build on soil that contains tree roots, or vegetation of any kind. If you’re digging in clay-rich soil and experience a rotten egg smell or other offensive odor, it could be rotting organic material in the clay. Invest the money in a consult with a geotechnical engineer if you have the slightest suspicion that the soil is questionable.

Before you purchase a vacant lot, do lots of due diligence. If it’s a new subdivision, obtain the cut-and-fill plan from the developer. Avoid lots that are on fill dirt. Look to buy a lot on an area that was cut as there’s a very good chance the ground on that lot mimics the rock of Gibraltar! That’s a good thing so long as you’re not buying a lot that’s all ledge and solid bedrock that requires blasting! That’s the other extreme of bad soil.

Column 1514