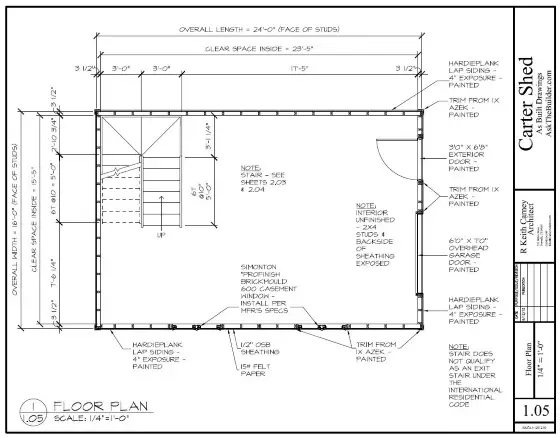

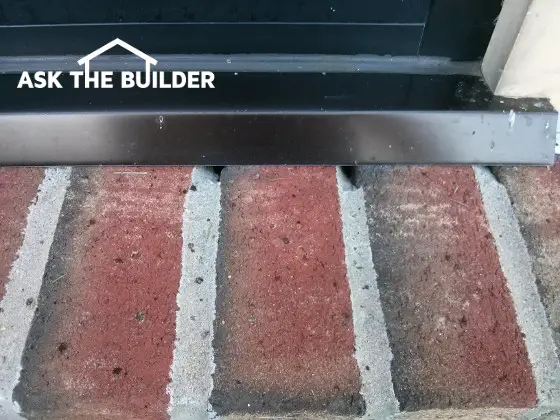

Water will obviously pour into the holes in the mortar joints in this brick window sill. It will also seep through where the mortar touches the brick. Look below for the best brick mortar. Photo Credit: © Copyright 2020 Tim Carter

Brick Window Sill Leaking TIPS

- Leak-proof brick sills are ones that have flashings under them

- Hard to retrofit existing brick sills

- Use thin bendable stainless steel for best flashings - SEE BELOW

- Solvent-based silane siloxane sealer could help stop leaks

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: After noticing some bubbled paint inside my home under a few windows, I did an inspection of the outside of my home and discovered holes in the mortar of my brick window sills.

It’s obvious water is getting into the walls at these entry points. If I just caulk these will my water leak problem be solved?

I’m beginning to wonder if the brick sills were installed correctly for this to happen. What’s the best practice for installing brick and door windows sills so there’s no water leakage? Maria S., Parma Heights, OH

DEAR MARIA: I commend you on noticing the problem in your home and then taking action to determine what might be the cause. All too often people ignore warning signs about things happening to their homes that might eventually turn into serious problems.

Free & Fast BIDS

How Do You Build Sills That Don't Leak?

I’d like to start by saying it’s going to be impossible for me in this limited space to provide you with the step-by-step process to create leak-proof brick window and door sills. One could easily write a book about the topic. But I’ll provide you with plenty of information so you have a crystal-clear understanding of what’s involved.

Do All Brick Buildings Leak?

Let’s start by discussing the water-resistance of brick buildings. I often find that most homeowners and business people consider brick structures to be waterproof. The truth is water enters into brick walls with relative ease.

In your case, with the holes in the mortar, it’s quite obvious water will pour into the cavity behind the brick.

Is Brick Veneer The Worst Leaker?

Yes, a brick veneer building is the worst leaker if not built correctly. Many modern brick homes and some commercial buildings are constructed with a brick veneer. This means the brick is just one wythe thick. The brick is just a facade and not offering any structural support whatsoever.

Older brick homes and multi-family structures you might find in just about any older city or town were often two, or even three, wythes thick. These thicker walls were not only structural in nature, they were designed to be highly water resistant.

Where Does the Water Leak?

While the brick itself is very resistant to water passing through it, and to a degree the mortar between the brick, the interface where the mortar touches up against the brick provides a pathway for water to enter into a brick wall. You can’t see this crack because it’s often very small, but it exists.

Why Don't Old Brick Buildings Leak?

Years ago, builders and brick masons observed what was happening and they used different brick in an exterior wall to help stop water from getting inside the structure. The brick that you’d see on the outside of the building was harder and denser than the brick hidden inside the walls.

This softer brick acted like a sponge to absorb water during a rainstorm. After the storm passed, it the water would be sucked from the inner brick by wind and sunlight that washed over the exterior brick facing.

Why Is Brick Veneer Bad?

Brick veneer buildings lack this soft inner brick and the water can flow down the back of the single layer of brick. If the structural wood-frame walls are not covered with a waterproof membrane, or this membrane has a leak in it, then water can get into the wall. This can cause wood rot, mold, mildew and bubbling paint as you know all about.

What is the Best Silane Siloxane Sealer?

You may be able to stop brick sill leaks by ensuring all cracks and holes are filled. Then you can apply multiple coats of the below solvent-based silane / siloxane sealer. Read the instructions to ensure you're doing the job right.

This is a magnificent silane - siloxane water repellent that soaks into concrete. CLICK THIS IMAGE NOW TO ORDER IT.

What are the Best Practices Flashings?

The best practices published by the Brick Industry Association call for flashings under window and door sills. These flashings collect the water that leaks through the mortar joints and redirects it to the outside of the wall.

This is a fantastic stainless steel flashing you can mold yourself to fit any brick sill opening. CLICK THE IMAGE NOW TO ORDER THIS AMAZING NO-RUST PRODUCT.

Base flashings are also required under the first course of brick as well as at other locations on brick veneer walls. NEVER use aluminum for flashing with brick. The alkali chemicals in the brick and mortar will cause the aluminum to corrode over time.

It's better to use stainless steel as it will never corrode in most locations. The only place you need special stainless steel is brick that's exposed to direct salt spray or salt fog near the ocean or a sea.

Water Channel Products

Other materials are often placed behind the brick veneer to ensure that wet mortar falling behind the brick doesn’t block the flashings and any weep holes at the base of the brick walls. These weep holes are installed on purposes and allow the water to flow out of the wall.

It requires a significant amount of skill and attention to detail to do all the things needed to ensure a brick veneer wall does not leak.

Should I Caulk Holes?

I’d not caulk the holes. I’d fill the holes with mortar that matches what you have. To match mortar, you need to get sand that matches the sand the original bricklayer used.

Look closely at the mortar joints paying attention to the size and color of the individual grains of sand. Realize when you mix up the new mortar the cement paste in the mortar mix will coat all the sand making the color of the mortar all the same shade.

Over time, natural weathering washes away the thin mortar film revealing the sand. If you wait thirty days, you can do a mild acid wash of the new mortar patches so you see the sand without having to wait decades.

Apply the acid/water solution very carefully to just the new mortar using a small brush. You’ll see the acid start to bubble as it reacts with the alkaline mortar paste. Rinse well with clear water.

What is the Best Mortar?

If you ever build a brick veneer home again, you can help minimize water leaking into the wall cavity by using the same mortar masons used well over a hundred years ago. Modern mortars have a high Portland cement content. Old mortars had minor amounts of Portland cement and much more hydrated lime.

The best mix for a lime mortar is to blend 8 parts hydrated lime with 2 parts of fine volcanic sand that has a high silica content. Light-colored volcanic ash usually has a high silica content. You then add this blend to the normal amount of sand you'd use to create traditional mortar.

Hydrated lime is a magical ingredient because if a small tiny crack develops after the brick is installed, water reacting with the lime causes new microscopic crystals to grow filling the crack in many cases. I urge you to find a mason that’s familiar with hydrated lime mortars.

This is excellent hydrated lime. It's a fine white powder and it's going to look great on your home. CLICK THE IMAGE TO ORDER SOME RIGHT NOW.

Column 1165