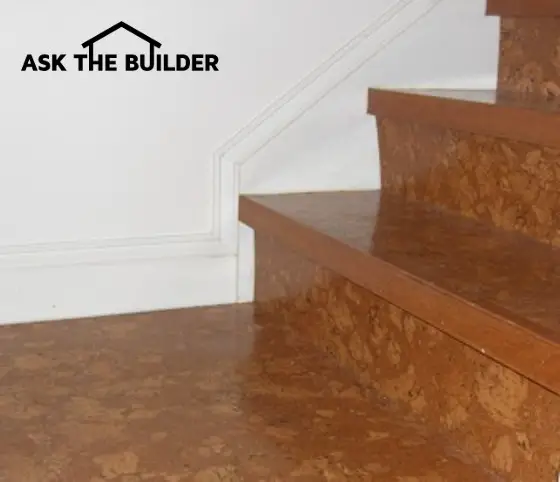

These cork flooring planks were used to cover the steps as well as the entire recreation room that’s at the bottom of the staircase. ©2017 Tim Carter

Cork Flooring Plank TIPS

- Cork flooring is extremely durable

- It's used in commercial buildings and strong enough for steps

- Easy to cut and install - coat with water-based urethane

- Different grades based on density - beware of cheap cork!

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: I’m very interested in cork flooring planks and wonder if it’s really as good as the salesmen tell me. Because money is very tight in these tough economic times, I’m looking for a discount cork floor.

The carpet store that advertises in my town has a cork flooring sale soon, so now’s the time to make a decision. Do you have experience with this material, and if so, would you install it again in a home you’d build?

Is it as durable as they say? How do you protect it and is it easy to clean? Leslie P., Santa Cruz, CA

DEAR LESLIE: I can understand you hesitating about whether cork flooring is really a suitable material to walk on day in and day out.

Cork Is Super Durable

After all, when you hold a cork from a wine bottle in your hand, you often see it’s somewhat friable. Hold a piece of oak in your hands and try to break it apart or chip it and your hands quickly wave a white flag.

CLICK HERE to get FREE & FAST BIDS from local flooring contractors who can install cork.

My First Time

I used to feel the same way about this magical flooring material, but was convinced shortly after seeing the first cork floor of my life. About 35 years ago, my father-in-law took me along for a ride to visit a business partner of his named Carl Hunsicker.

This man lived in a custom-built home that overlooked the Ohio River at the edge of a bluff. When we walked into Mr. Hunsicker’s kitchen, I looked down and saw the strangest floor.

Wide Long Planks

He had cork kitchen flooring. It resembled the deck of a ship as the planks were very long and approximately 8 inches wide. It was drop-dead gorgeous.

When I asked what kept it from disintegrating as you walked on it, Mr. Hunsicker chuckled saying, “Son, you don’t have to ever worry about this floor wearing out.”

Public Library Floor

I later discovered that cork flooring was used in many commercial and institutional buildings that receive heavy foot traffic. The main library in Cincinnati, Ohio, had a cork floor for years that millions of people walked on.

This floor is still in the library, but now if you go there it's covered by giant rolls of commercial carpeting.

This is the exact cork flooring I used in my entire finished basement, including the AsktheBuilder.com world headquarters. CLICK THE IMAGE NOW TO ORDER IT FOR YOUR HOME.

Tough Enough For Steps

You don’t have to worry about durability if you purchase a high-quality cork floor.

To give you another example of it’s extreme toughness, I installed cork plank flooring tiles on the steps that lead to my basement.

Many people don’t realize that steps are the best place to test flooring as your foot typically slides on the tread surface as you climb the steps. There’s much more friction than walking across a normal floor surface.

CLICK HERE to get FREE & FAST BIDS from local flooring contractors who can install cork.

Tons Of Stain Solver

Stain Solver is MADE in the USA with USA ingredients that are food-grade quality. CLICK THE IMAGE to order some NOW.

My basement steps got extremely heavy traffic because our home office was in several rooms downstairs. We also ran a cottage business shipping a magical cleaning product from the basement.

We made tons and tons of Stain Solver in the basement in a room right at the bottom of the steps. Stain Solver is a certified organic oxygen bleach that cleans anything water washable.

It's a fantastic product you should try. We would carry up tons of boxed Stain Solver up the steps adding even more friction. What's more, we'd have some of the Stain Solver grit on our shoes. The cork on the steps never showed any wear, but I digress.

Clean & Look Closely

One day I cleaned these steps getting them ready for an open house. They looked like the day I installed them.

I owe much of this to the toughness of the cork, but also to the fact that I had originally coated the cork with five coats of high-quality urethane. I knew the steps would be abused, so I wanted plenty of urethane between the bottom of the shoes and the actual cork.

Oak Stair Nosing

Another thing that helped the cork on my steps was the custom oak nosing I installed.

Because I knew that the shoes would be sliding onto each tread, I had the top piece of oak milled so that it was 1/64th of an inch thicker than the thickness of the cork planks that were glued to the steps. This prevented the shoes from wearing away the front edge of the cork on each tread.

Use Best Urethane

I used clear water-based urethane to protect my cork on the steps and the cork that was on the floor in the entire basement. It was easy to apply, and has allowed the cork to maintain its beauty for the past ten years.

SECRET TIP is to coat the drywall BEFORE finishing with this amazing urethane product. It WILL STOP water from penetrating into the paper of the drywall. CLICK IMAGE TO ORDER IT NOW. Always be sure to order the exact sheen you want. There's a big difference between satin and high-gloss!

Clean With Water & Mild Soap

Cleaning it is easy. I just use regular liquid dish soap and water to clean up spills. For regular moping, I add 8 ounces of white vinegar to two gallons of warm mop water.

It's also safe to use Stain Solver on cork flooring if you get a tough stain on it.

Be Careful Of Discount Cork

Be very careful purchasing discount cork flooring. Not all cork flooring is made the same.

There are different densities of material. The best way to determine what’s good and what’s not is to go discover the most expensive cork flooring you can find.

Cheap Cork REJECTED

Talk to the manufacturer and ask why it’s so expensive while others are not. You’ll quickly discover that the low-cost flooring often contains cork that might be rejected by quality manufacturers.

Consider A Test

If you’re still in doubt about how well cork flooring wears, make up a test panel. Attach pieces of cork to a thin piece of plywood and coat them with three coats of clear urethane. Set this panel in your home someplace that gets heavy traffic. Monitor how it looks after three or four months. You’ll be amazed for sure.

CLICK HERE to get FREE & FAST BIDS from local flooring contractors who can install cork.

Column 821