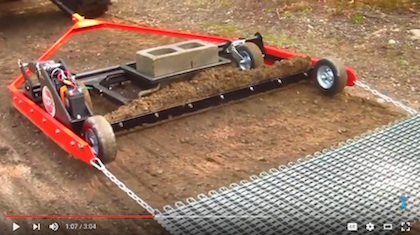

Bearing Wall Footing | This massive long block of poured concrete is a bearing wall footing. It will be covered with more concrete that forms the lower level floor. Photo Credit: Tim Carter

Bearing Wall Footing - Or What is that long block of concrete in my Basement?

DEAR TIM: My wife and I are building our new home and we stopped by to see the progress just after the foundation was poured. We saw a massive long block of concrete at least 10 inches thick in the middle of the basement floor. I don’t see how our basement floor will be smooth now with this giant thing in the way. What is it and why would the builder go to this much effort and waste this amount of concrete? Is it too late to remove it? I see pipes passing through the bottom of this concrete. I took lots of photos of this monolith. Stephen B., Dover, DE

DEAR STEPHEN: You’re doing the right thing stopping by your new home construction site. I hope you’re taking hundreds of photos of everything you see. I clearly remember the first time I was around a new home job site smelling the freshly turned earth, the lumber and all the other aromas associated with building. That and all the progress being made my excitement meter needle move.

Take Pictures

With modern digital photography, and massive amounts of memory in smart phones and cameras, it’s a wise thing to take hundreds, if not thousands, of photos of your construction projects. Be sure to take close-up photos too. These photos will become invaluable at a later date as things you see now eventually get covered up with dirt, concrete, insulation and drywall. I also urge you to take videos of what you see talking about what you see and what you’re looking at while you move the camera around.

You want to be able to know where everything is and what was there before it gets covered up. Even though you think the photo you’re taking is of nothing, an expert in the future may be able to see valuable pieces of data in the photo. I urge you to download the photos each day and place them in file folders so you know what the photos are at a future date. Be sure to backup this data so the photos and videos are never lost.

Bearing Wall Footer

I looked at your photo of that massive block of poured concrete. Without looking at your blueprints of the house, I’m quite certain it’s a bearing wall footing. Take a look at your plans and blueprints and my guess is you’ll see a wall that’s going to be in this location in your new home.

The floor joists above this wall will run perpendicular to the wall and this massive block of concrete. The wall below supports these joists. What’s more, there could be another wall upstairs that’s directly over the wall in the lower level. That wall no doubt will have floor joists passing over it at a 90-degree angle too.

Depending on how your roof is going to be framed, there’s a possibility that some of the roof load could transfer down through the center of the home as well. The bearing wall footing you see now in the basement will support all this weight and transfer it over a wider area to the soil beneath the footing.

Will my Basement Floor be Level?

To the untrained eye, you may think this massive concrete block is at the same level, or even higher than what your concrete basement floor will be poured. Mistakes have happened and contractors have poured these footings too high, but it’s rare that this happens.

I think what you’ll probably discover if you stretch a string is that the top of the bearing wall footing is at the same elevation as the top of the footings that your poured foundation walls rest upon. There is no need to remove the bearing wall footing unless it somehow is too high.

It’s a common practice for the basement slab to be poured so it rests directly on top of the footings. The void space between the footings where you see bare soil should be filled with granular clean fill material. I used washed pea gravel for the homes I built.

Some builders use a mix of sand and gravel. If you see piles of material brought in by dump trucks at your site now that have lots of sand in it, this is what’s going to be used. Be sure this material is compacted before any concrete is poured in your basement.

The pipes you see in the bottom of the footing are most likely passageways that allow ground water that might collect under the slab to flow toward the foundation walls. If your builder is doing a great job, you should see a few of these pipes under the footings that are below the outer foundation walls.

These pipes on the outer walls should be located on the side of the house that faces the lowest spot on your lot. Assuming there is fall or slope to your lot, the builder will hopefully dig a trench at some point and place a drain pipe that connects to the drain tile pipe that surrounds your foundation.

This pipe in the trench is the conduit through which groundwater passes so it doesn’t enter your basement. All too often most builders don’t install this very important drainage feature. The pipe will eventually exit at ground level and water will flow from it in periods of wet weather. Make sure it happens on your job.

Column 1146