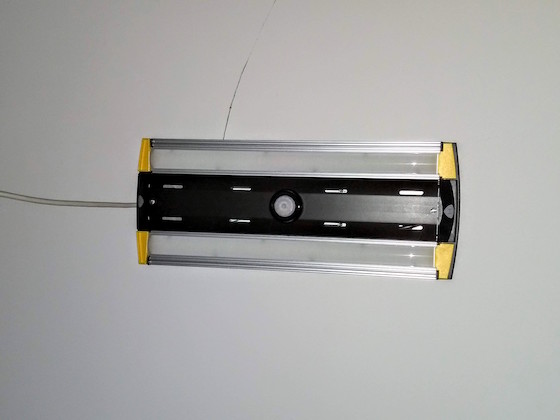

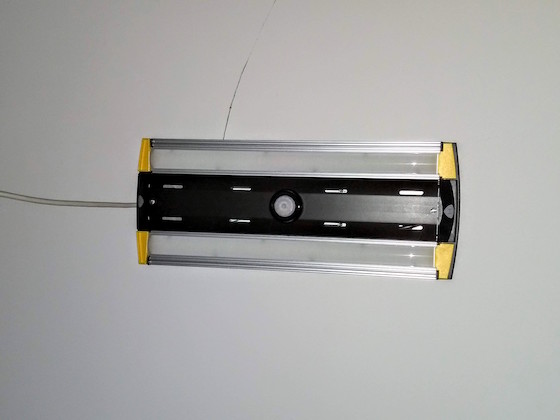

This is the Big Ass LED light. It's small, but it puts out LOTS of light. Copyright 2018 Tim Carter

Big Ass LED Light - Small but Bright!

A few months ago, I was approached by the fine folks at Haiku Home. They make fans and they recently started to dip their toes into the LED light marketplace announcing their Big Ass LED Light.

The engineers at Haiku Home came up with a durable, futuristic, and BRIGHT LED light meant for garages, shops and any other place where you need lots of light but not a big electric bill.

What are the Specs of the Big Ass Light?

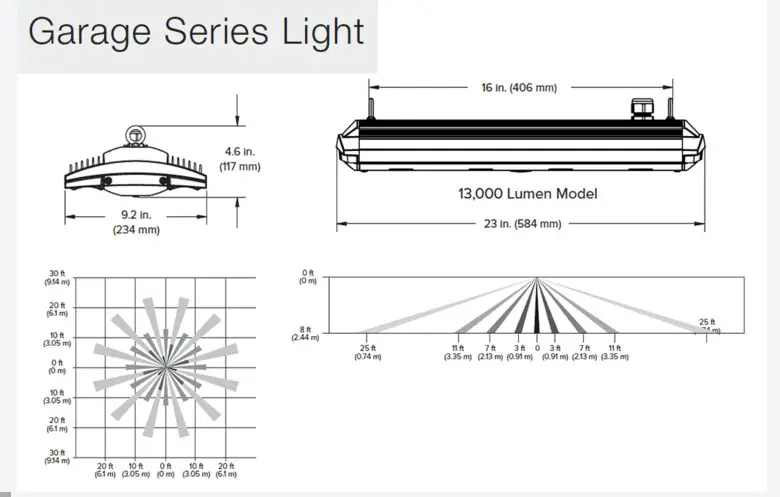

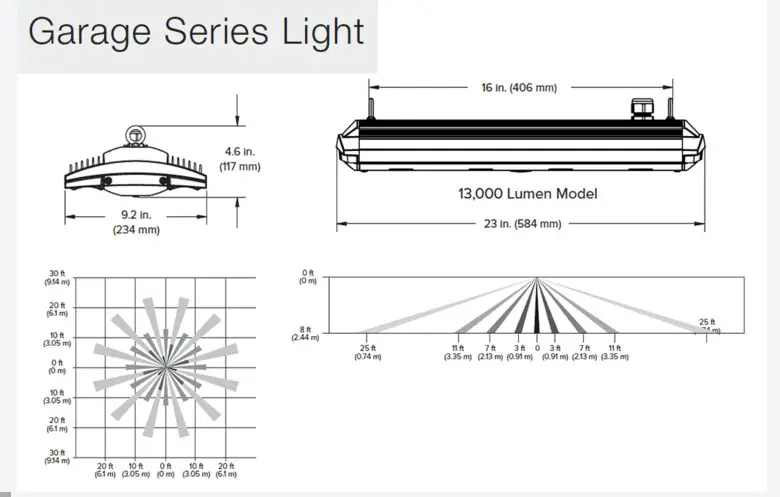

This 2-foot light fixture made from a one-piece cast aluminum body puts out a brilliant 13,000 lumens while only sipping just 122 watts from your local electric provider. The color temperature of the light is very close to what you'd see at high noon on a clear day.

What is the Color Temperature of the Big Ass Light?

You can expect 5,000 Kelvin out of these lights so you get excellent color rendition with whatever you're working on.

How Much Does it Weigh?

When I first took delivery of the lights, I was astonished at what the lights weighed. I wondered if they incorporated lead weights in them.

I estimate the light weighs 15, or more, pounds. They're beefy and definitely deliver with respect to the THUD factor.

Click the image to purchase this light.

How Do You Hang the Lights?

You hang the lights with two included S-hooks. A standard three-prong plug provides the needed electrons. This means you'll have to adapt a standard lightbox in your ceiling to an outlet that you might find on a wall.

Does the Big Ass Light Have a Motion Sensor?

The light comes equipped with a motion sensor that can be adjusted to suit your needs for how you use your garage or workspace. This is a very handy feature and a twist of the sensor allows you to adjust the length of time you want the light on each time you activate the switch.

You can visit the Haiku Home site for all the details about this amazing light fixture.

How Much Does the Big Ass Light Cost?

My biggest complaint with this wonderful light was its price. At the time I'm writing this review, you have to part with just a few pennies under four hundred dollars for one of these at your local big box store.

For some reason, there's a very wide disparity in price if you go to Amazon.com where the light is listed at an astonishing $599.00 at the time this review was published in early April 2016.

The Big Ass LED Light comes with a corresponding big-ass price tag that many might not be willing to spend.

Click here to purchase this light

With that in mind, I decided to ask Clay Moran at Haiku Home some questions. I was trying to get my head wrapped around why a garage light would be so costly.

Here they are with his thorough responses:

Why are the lights so expensive? Can you go into detail as to what makes them retail for $500 when you can go to Amazon and get similar light fixtures for far less?

There are several reasons our lights are the priced the way they are. These fixtures are-and I mean this sincerely-not comparable to anything else out there. They are incredibly bright – brighter than (16) 60-watt bulbs. Each light is assembled in the U.S. and every light goes through a burn out period before they are shipped to ensure the highest quality. The benefit of this is we catch any faulty LED bulbs before they are shipped out. Most lighting manufacturers test one fixture for every 100 they sell. Our lights are made of one solid piece of extruded aluminum, which means you never have to worry about breaking bulbs in your shop. Our lights are so durable, in fact, that you can drive a 4 ton truck over them without a scratch. We know, because we did it - see here. The expected lifetime on our LED’s blows CFL’s out of the water and means that you should never have to purchase another light. Most companies provide a 1-year warranty, and we provide a full 7-year warranty that includes the driver (power supply).

Are there vast differences in components? If so, what? Please go into great detail about how you might have far superior components vs the other brands.

In addition to the information above, the Amazon link that you sent primarily shows bulbs, while our product is an entire fixture with lighting already installed. Besides hanging or securing as preferred, the only real installation required is plugging our light into an outlet. Further, when installed with the occupancy sensors, our customers have the potential for energy cost savings from eliminating wasted time with the light on.

The lights seem unnaturally heavy. Why? Was the weight done for the THUD factor because of the price?

Not at all, as mentioned above, we want our lights to be the last our customers have to buy, so they are made from one solid piece of extruded aluminum for maximum durability. This comes with some extra weight!

Who is your customer? What is the demographic? Very few have the spare cash to spend $500 for a garage or shop light.

We have a huge demographic of customers- most male, 30’s-60’s in age, and especially popular among the wood-working population and for customers who work on cars or other projects in their garage and require bright, long-lasting, durable lighting.

Any other information you can provide to justify the cost would be quite helpful.

An additional feature that adds convenience and ease of use to the lights is the easily removable lumen maintenance trays. These can be removed, cleaned, and replaced in just minutes, which is fantastic for folks with a lot of sawdust, grease, or other grime flying around their shop or garage.