Patton Opening Scene

This is a very powerful motivational speech. Listen to it very closely.

This is a very powerful motivational speech. Listen to it very closely.

Renovating an Old Building | This modern loft apartment was built in 1890. The brick shell and massive wood floors were in great shape, but everything else had to be redone. Copyright 2022 Tim Carter

Not a week goes by that I don’t receive an email asking me about what’s involved in renovating an old building. Most who reach out to me realize it can be an expensive endeavor, but the allure of restoring a sound old building to either its former glory or transforming it into an attractive modern look sometimes overrides the financial aspects of the project.

And as you’re about to discover, there may be a lucrative investment opportunity you’ve not thought about when it comes to old buildings. A little over a week ago I stayed in a renovated one-bedroom loft apartment that was part of a solid brick building built in 1890 in the East End of Cincinnati, Ohio.

The owner of the building is a long-time friend of mine. At the time he renovated the building five years ago, he was doing construction and real estate investing. I was nearly 1,000 miles away, but he sometimes called me to ask for advice when he was faced with a problem or a difficult choice. I was always happy to help him.

Keep in mind that when you build just about anything, you have choices to make. All too often I see people make poor choices. They select products that have a short useful life or require lots of ongoing maintenance. With raging inflation and a tight labor market that I don’t feel is going to improve in the coming years, ongoing maintenance can become a vast bottomless money pit.

Fortunately my friend made all the right choices when it came to the renovation. He knew he was going to keep the building for many years to create a passive income stream. He owned a handful of other buildings on the same street and the neighborhood was being reborn. It was exciting for me to watch this transformation from a distance.

My friend made wise decisions about all sorts of materials that cost a little bit more to install now, but would be virtually maintenance-free for many years to come. Here are a few examples. He could have installed standard asphalt shingles on the steep roof, but instead he went with standing-seam metal roofing. This metal roof will not require maintenance for at least 40 years.

He had to install both interior and exterior staircases. He could have just used treated lumber outside and standard lumber inside. But no, he went with industrial-sized steel outside with cast concrete treads. Even the handrails and guardrails were made from wrought iron that can last well over 100 years with periodic painting every ten years.

I remember a conversation we had about what was the best exterior paint to use and I shared that he should go with one that has a urethane resin base. I painted my last house in Cincinnati about 25 years ago with this type of paint and the paint looks as good today as it did decades ago.

There are things you should be aware of if you decide to do an old-house renovation. First and foremost be aware of the lead-paint hazards. Be sure to test any and all painted surfaces that you’ll be working with. Note that even old clear varnishes sometimes had lead. Small amount of lead can make you very ill, so you need to treat lead paint with the utmost respect.

In almost all cases you’ll have to install all new mechanical systems. Budget for all new plumbing drain and water lines. You’ll want to install all new electrical wiring. Be sure you install 20-amp circuits in critical locations so you avoid tripped circuit breakers in the future.

Most of all don’t cut corners on the heating and air-conditioning. This system is what keeps you comfortable year-round. It’s vital the contractor does accurate heat-gain and heat-loss calculations so the equipment is sized properly. Be sure you have return-air vents in all rooms except for the kitchen and bathrooms. The return-air system needs to be designed properly as it ensures each room is comfortable no matter what the outdoor temperature might be.

If your goal is to renovate a property to rent, don’t overlook the possibility of short-term rentals. My wife and I rent houses several times a year when we go visit my daughter, her husband, and my granddaughter. There are many people who prefer to do this rather than being crammed into a motel or hotel.

When you do the math, you might discover you can double your rental income using short-term rentals. You might only need to rent the space for 120-150 days a year to achieve this financial result. In many cases the building might get far less wear and tear vs. renting to a tenant that lives in the space everyday all year long.

Column 1481

The X Files was a fascinating television series.

Here's some footage shot in 2015 or possibly 2016 which means it was probably scripted a year before that.

Watch it with an open mind. Realize tens of thousands of people are now dying mysteriously, many of them healthy young people. Have you wondered why? Have you even been exposed to this news?

If not, that should send a chill through your bones like a January New Hampshire Nor'easter.

Be prepared to have your mind opened up:

How many mistakes do you see in this photo? I count over four. Keep reading below! Copyright 2022 Tim Carter

Over the past five months I’ve watched the dream of a neighbor I’ve yet to meet start to come true on my own street. It started just after the snow melted when two men arrived with a giant machine that wrestles logs and chain saws. Their job was to cut down and haul away no less than fifty trees on the stubborn hilly building lot.

I remember starting jobs and feeling that excitement. Those same endorphins rushed through my body when I broke ground on the stunning Queen Anne Victorian home I built back thirty-six years ago for my family.

However, as the weeks have progressed my new neighbor’s dream is slowly transforming into a ghoulish nightmare. Sadly they may not be aware of this. I’ve been chronicling the progress with lots of videos explaining what’s going on. The sad thing is the mistakes I’m seeing are all based in misplaced trust. I get at least fifty emails a week from homeowners just like you who have made the same mistake.

WATCH THE ENTIRE VIDEO PLAYLIST of all his mistakes. Videos are added WEEKLY until the job is complete or they run me off:

Just days ago carpenters showed up to put the first layers of wood on top of the poured concrete foundation. Weeks ago I witnessed the foundation being installed and based on my past experience I sensed there would be mistakes made. My instincts were not to be denied.

The lead carpenter should be congratulated because I know for a fact he checked the foundation for level. He might have used a high-quality optical builder’s level or he could have used a laser level. Within a short time, he discovered a long side wall and a short return wall were out of level by 1 and I/4 inches. That’s a huge variation and unacceptable.

It’s important to realize that everything that follows is speculation because I was not privy to any conversations. It’s entirely possible the carpenter called the builder making him aware of the problem. This, by the way, is one of the other mistakes I’ll expound on shortly.

The carpenter should have told the builder that he wasn’t going to install the two sill plates until such time as the out-of-level foundation was corrected using a time-tested thin concrete overlay using coarse sand and Portland cement. This repair could have been done in less than four hours by two men. The materials for the repair would have cost less than $25.00.

This repair didn’t happen. Instead, the carpenter proceeded to bolt the treated-lumber sill plate to the concrete and then install the untreated plate next. He leveled this second plate using cedar shims that are water-resistant, but not waterproof. That was another mistake.

We already know the foundation contractor made the error. It happened, in my opinion, because he failed to snap level lines on the inside of both sides of the forms. Once the chalk lines were snapped, a worker would install 4 or 6-penny finish nails spaced about six or nine inches along both chalk lines.

The magnesium float used by the foundation contractor to smooth out the wet concrete would glide the tool along these nails ensuring the top of the foundation was level. It would have taken about an hour for one man to install these nails. Such a sad mistake to skip this simple step.

The builder, whom I’ve yet to see in five months, made no less than two mistakes in my opinion. Once the foundation forms were placed, he should have stopped by the job site to check to see how the foundation contractor was going to ensure it would be level.

After the forms were stripped, the builder could have set up a laser level by himself and determined the foundation was out of level. This could have been done in less than 15 minutes. There are all kinds of possibilities at this point. He could have seen the error and ignored it or selected the wrong solution to the problem.

Now it’s time to lay part of the blame at the feet of my new neighbor. You see, I’ve done thousands of autopsies on similar situations in the three decades of wearing the Ask the Builder hat. The biggest mistake the homeowner made was hoping everything was going to go well. He didn’t do a great job of vetting the builder with his $1,000,000-plus investment.

The homeowner probably didn’t have in-depth meetings with all the bidders on the job to go over the plans and specifications. My guess is the homeowner didn’t make it crystal clear what his expectations were. He just hoped those expectations would be met. I doubt the homeowner had an hours-long meeting with the builder to go over his bid to ensure the builder calculated all the right amounts to meet the homeowner’s expectations. You have to do this before you sign a contract.

Here’s the flip side to this. My son just purchased a new home in the spring just 60 miles south of me in southern New Hampshire. It’s the best built home I’ve seen in the fourteen years I’ve lived here. My son discovered from a neighbor that the builder spent many days at the job site to ensure everything was done correctly. He did this quality control each and every day. Is your contractor going to do this, even for a small two-week job? How do you know? Stop hoping. Stop trusting

Column 1474

I was the first person in the world to identify that copper prevents the oxidation of asphalt molecules on asphalt shingles. See how easy it is to install this copper in a new-roof installation? CLICK the photo or TAP HERE to order the copper strips.

A week ago I made a decision to ratchet up my ability to save you as much money as possible in these very challenging financial times. Inflation is raging. In my opinion, it’s going to get worse. Each day I’m receiving more and more emails at my website like the one I got from Beryl about the roofs in her giant condo complex. Go here to tell me what issue you’re having. I’m going to address as many as I can in future columns.

Beryl’s email was deeply troubling for a number of reasons. First, I could sense the fear in her cry for help. She said she lives in a community of seventeen free-standing two-story duplexes from what I can tell from her photos. The development was built in 1985 and the roofs were replaced in 2005 after twenty years. The current shingles on the condos have a 30-year warranty. They’re now 17 years old.

Beryl said they’re experiencing some leaks and failures not related to ice and snow. The worst part is she said the condo board is budgeting the staggering sum of $1,000,000 to replace the roofs eight years from now. Doing the math, that’s over $58,000 per building.

I only knew the city where Beryl lived and she had sent me a low-resolution photo of the buildings taken from her deck or patio. Using Google Maps in the satellite mode I was able to locate her development in less than a minute. I then used parked cars for scale and determined that each of the roofs on the buildings averaged about 85 squares or 8,500 square feet of roof area.

Taking inflation into account and what it might be eight years from now, it turns out the board’s estimate could be very accurate. It’s a mind-numbing number and imagine what kind of special assessment each condo owner will have to cough up like a bad hairball to pay for the new roofs!

How does this affect you? The odds are you have an asphalt shingle roof on your home. The vast majority of homes and small businesses in the USA use this disposable roofing material. You might wonder if it’s possible to have an asphalt shingle roof last fifty or even sixty years like the one on my friend’s house in Los Angeles. It is possible.

Beryl and her fellow condo owners may not have to spend all that money in eight years if their current roof is in great shape. They can add copper strips at the top of all the ridges on the roofs and dormers that will arrest the aging process of the shingles. While writing my Roofing Ripoff exposé book five years ago, believe it or not, I was the first person in the world to discover that copper ions bond with asphalt molecules. When this happens, it prevents the asphalt molecules from cross linking using oxygen.

Cross linking makes the asphalt more brittle. When the asphalt becomes brittle, shingles start to curl and lose the granules. The colored granules are incorporated into shingles to prevent them from failing in a few years. Think of them as sunscreen like you use on your skin to prevent sunburn.

Look at how the small amount of the copper on the roof of the cupola prevents the shingles from aging.

I cover all this in great detail in my short easy-to-read book. What’s more, I have the photographic proof that copper works and the feedback from three physical chemists who subscribe to my newsletter.

If you have a new asphalt shingle roof or one that’s older but in fantastic shape, you can extend its life by decades if you simply install thin rolls of copper at the top of the roof ridges. The copper should be blind nailed as you see in the following photo so it doesn’t get destroyed by wind storms. Each time it rains, copper ions wash off the strips and bond with the asphalt that you can see in between the colored ceramic granules.

If you NEED HELP understanding how to install the copper, I do affordable phone consult calls. You can even order a transcribed and recorded call so you don't have to take notes! Go here to set up a call.

I was the first person in the world to identify that copper prevents the oxidation of asphalt molecules on asphalt shingles. See how easy it is to install this copper in a new-roof installation? CLICK the photo or TAP HERE to order the copper strips.

The best part is the bright new copper turns a deep nut brown in about eighteen months. On low-slope roofs you can barely see the copper when standing on the ground. It’s easy to install the copper as part of a new roof installation. It’s a bit more work to install it on existing roofs in good shape where the shingles are still flexible when heated up by the sun.

You may wonder if zinc strips will do the same thing. I can’t tell you as I didn’t test zinc and the test takes about 20 or 30 years to complete. To get the maximum benefit from the copper you need at least six to ten inches of it exposed for every 25 feet of shingles that are below the copper. I had ten inches of copper exposed on each side of my daughter’s roof.

Keep in mind the copper must be exposed to direct sunlight during the day for this to work. The sun launches photons at your roof constantly and when they hit the copper at a speed of 186,000 miles per second, they dislodge the copper ions. These then get washed down the roof the next time it rains. Your roof is very important so it’s vital you do all you can to extend its life.

What can I help you with? What issues around your home worry you? What do you want me to discuss in my upcoming columns? Go here and tell me.

Column 1477

Mineral deposits and grit in your faucet aerators might be the only reason you have dismal water pressure. Copyright 2022 Tim Carter

Christine lives in Sylvania, Ohio. She reads this weekly column and shared the following, “In the newspaper today you said you’re addressing topics that can save homeowners money. In my community many have water pressure issues, myself included.” She then gave me a full report about her particular water-pressure issues.

As often happens a reader shares the key that unlocks the mystery without me having to ask any questions. Christine said, “…and have had issues in different parts of the house while other faucets are fine.”

Bingo. There’s your smoking gun.

Does this describe what’s going on in your home? If so, I’ve got such great news for you. Within a few hours you can restore the full flow of water in all your faucets. You can do this yourself using a simple tool and some simple chemicals you may already have. You may spend less than a dollar to restore your water pressure.

I've been a master plumber since 1981 and solve plumbing problems of all types each week on the phone. I talk to homeowners just like you. Go here to set up a call. Note you have choices and I even offer a transcribed call so you don't have to take notes!

First allow me to explain Christine’s clue. I often think it’s hard for some people to understand water pressure in homes because the water lines are hidden from view. It’s not hard for you to understand how tree leaves get water because you can see with ease the tree trunk, the branches, and eventually the tiny twigs that extend to each leaf.

Think what happens if you were to cut a 1-inch-wide band of the tree bark from around the entire circumference of the trunk. Since the live-giving sap travels up from the roots to the leaves just under the bark, the tree would soon die as you’ve cut off the pressure completely. But what happens if you do the same thing to just one major branch? Just the leaves on the branch die and the rest of the tree is fine.

You may have poor pressure in one or more faucets simply because of a localized issue at that faucet, not an issue within your main water line. In fact, I had the same thing happen here at my own home over the past few months. Go here and see if you have these problems with water pressure.

Living in a rural area, I have my own well. I also have a water-conditioning system that has a whole-system pre-filter. The filter helps protect the filtration media that treat my water. The 5-micron paper filter needs to be changed every three to four months for optimal performance. Believe it or not, I forgot to change the filter.

The first sign of trouble was iron staining as the filter had become clogged with tiny iron deposits and now some was getting past the filter. Then I slowly started to notice that the flow of water from my kitchen faucet was less than satisfactory.

But when I’d go to use my laundry sink to fill the bucket to wash my truck, I’d not see any water flow issues. Keep in mind, the laundry tub faucet doesn’t have an aerator. Aerators are huge money makers for plumbers. Aerators are put on the ends of kitchen and bath faucets to tame the flow of water. If you’ve not looked at one up close, you should because they’re primarily miniature filters.

I removed my kitchen faucet aerator and lo and behold there were visible pieces of grit sitting on top of the top screen. Who knows what smaller things could be deeper inside? I also saw severe iron staining and felt that iron deposits could have started to restrict the flow within the aerator.

I opened my refrigerator, got out my bag of oxalic acid, heated up four ounces of water in a small glass container, dumped in a teaspoon of oxalic acid powder, stirred it, and dropped in the aerator into the solution. I then walked away for 30 minutes.

When I came back, the aerator looked like new. I rinsed it and then started phase two of the cleaning process. I wanted to make sure I removed any and all hard-water deposits. I threw out the oxalic acid solution outdoors on some crabgrass, rinsed the container and put in four ounces of white vinegar. I heated it up in the microwave for one minute so the chemical reaction would occur faster.

If you recall your high school chemistry class, you know that white vinegar is a weak form of acid and that hard water deposits are alkaline. The weak acid dissolves the deposits. I dropped the aerator into the hot white vinegar and let it soak for several hours.

Once I put the aerator back on the faucet, the flow was back to normal. If you don’t want to go through this multi-step cleaning process, you can often just install a new aerator. Take your existing one to a neighborhood hardware store and they should offer a suitable replacement.

What can I help you with? What issues around your home worry you? What do you want me to discuss in my upcoming columns? Go here and tell me.

Column 1478

This is deep rust staining on an expensive acrylic bathtub/shower unit. Can the rust be safely removed for less than $1? Yes it can! Copyright 2022 Tim Carter

Not a week goes by that you, or another reader or two or three or twenty, might reach out to me with a fantastic question about the column of mine you’re reading. Often you might ask why I failed to dive deeper into the topic. You may not realize this, but your newspaper that publishes my column often has a limited amount of space where my words and photos must fit. I need to adhere to that word-limit restriction.

About a month ago this column was devoted to removing rust from my own toilet. I received an avalanche of great questions that were not covered in the column. So many that I felt a follow-up column on rust removal would help you save thousands and thousands of dollars. Let’s get started.

The most frequent question of all revolved around two related topics: will the oxalic acid harm the plumbing pipes in my home and how does one neutralize the acid? Weak oxalic acid will not harm PVC or ABS piping. Plastic drain pipes are generally immune from any and all weak acids. Cast iron drain pipes and acids don’t play well together with acid so it’s important to neutralize the acid before you allow it to flow through the pipes on its way to the city sewer or septic tank.

You neutralize an oxalic acid solution adding ordinary baking soda. Start to pour in some into the solution. It should bubble. Stir carefully and continue to add more soda powder until the bubbling stops. The best way to check to see if the solution is neutralized is to use litmus paper making sure the solution has a pH of 7.0. Adding lots of water to the solution will also dilute the acid.

You may have wanted to know if the oxalic acid would hurt your septic tank and the biologic activity inside the tank. Well, we know for a fact it won’t help it! The safest thing to do when cleaning anything using an oxalic acid solution would be to prevent the solution from going down the drain. Capture the acid solution and take it outdoors to pour onto the ground once you’ve neutralized it.

Next up I received quite a few questions about how safe it is to clean acrylic tubs and showers, chrome faucet parts, ceramic tile and all sorts of surfaces in a normal bathroom that might have rust stains. I’ve got great news for you. In my experimentation at my own home, I’ve discovered the oxalic acid solution doesn’t harm anything other than polished marble. Keep any and all acids away from marble.

Here’s the best advice I can offer before you start to apply an oxalic acid solution on anything. Mix up a small amount of the solution and use a cotton swab to apply a drop of the acid solution to the object. Let the acid sit for about an hour. It’s vital that before you apply the drop that the area is clean and dry. It helps that it’s also in an out-of-the-way spot so if the acid does damage the sheen, you don’t notice it that much.

You may have reached out to me about using oxalic acid outdoors to clean rust from vinyl siding, brick, mortar, concrete, etc. You get rapid results when cleaning vinyl siding but you’ll discover it takes quite a bit of time to get great results on rock, concrete, brick, mortar, etc. This is because the rust can soak into these surfaces. You just have to be very patient and try to work in the shade so the oxalic acid solution doesn’t evaporate.

Oxalic acid solutions are the go-to cleaner for exterior redwood. If you recall your high school chemistry, you’ll remember that acidic solutions have a pH lower than 7. Caustic chemicals like many oxidizers have a pH higher than 7. Redwood can turn black or darken if you use anything with a pH higher than 7.

This is why you never want to use chlorine bleach or any other oxidizer to clean redwood. All that said, always TEST using an oxalic acid solution solution to clean your redwood or any other surface. I can’t stress that enough. You can’t hope everything is going to work out fine. It only takes an hour at most to run a test.

Just about everyone who reached out to me asked where’s the best place to purchase oxalic acid. Fortunately it’s a very affordable product and I bought mine online from Amazon. I got a sizable pouch of the white powder for less than $15.00. You may discover a local national-chain hardware store stocks these pouches.

This is a re-sealable bag of oxalic acid crystals. Go HERE to get it delivered to your home NOW.

Always read the instructions about how to mix, use and store the unused acid. My pouch is sitting on the bottom shelf of my refrigerator right now next to cartons of milk. Oxalic acid powder likes to be stored cold if at all possible. If you’ve got kids in the house, be very careful where you store it. You never want the possibility of a child thinking the acid is powdered sugar. It looks just like it.

What can I help you with? What issues around your home worry you? What do you want me to discuss in my upcoming columns? Go here and tell me.

Column 1479

Fill out the form below. Share with me in as few words as possible what you need help with.

GO TO THIS PAGE AND USE A DIFFERENT FORM if you have HELPFUL PHOTOS to upload that will help me understand your situation.

If you want FREE weekly tips you should sign up for my free-for-life newsletter. I share many things each week not found in my syndicated newspaper column.

Parts in a Toilet Tank | Here’s a rare photo of a toilet that you’ve undoubtedly never seen. It’s the underside of the commode with a new wax gasket applied to the outlet hole. Copyright 2022 Tim Carter

I’ve been a master plumber since 1981 and I want to share as much of my accumulated knowledge with you as possible in these turbulent financial times. As we move down the timeline, I’m going to try to save you money each and every week. You need to know about the parts in a toilet tank AND you need to know about the toilet bowl beneath it as well.

Let's get started.

Toilets are much-needed fixtures in the average home. While they appear complex, they’re not. Once you understand the simplicity and elegant way the average toilet incorporates the physics you discovered in high school, you’ll soon be able to tackle any and all repairs yourself. What’s more, with my help you can even remove and install a new toilet by yourself in less than an hour if that’s what you want to do! I’ve got step-by-step instructions how to do this on my AsktheBuiler.com website.

Let’s start with the toilet bowl. When you flip up the toilet seat cover you should see a standing pool of water. That water is sitting in a u-shaped trap no different than the u-shaped pipe under your sinks, tubs, and showers. You only see half of the water. The other half is in the bowl colon. This colon passageway curls up and then down again creating the pathway to the drain pipe.

This water in the bowl serves two purposes. First and foremost it provides a barrier for sewer gas and vermin from entering your home. Without this water, foul-smelling invisible sewer gas would waft into your home much like smoke rises off a burning stick of incense. Vermin need to be excellent deep-dive swimmers to make if from the hidden side of the trap to the room side that you see when you peer down into the bowl.

The water spot is supposed to make it easier for the toilet bowl to stay clean when solid waste is deposited into the bowl. Back years ago when the generation-one 1.6-gallon-per-flush toilets were introduced, many had a smaller water spot. Customer complaints got rid of this design faster than a short-order cook flips burgers during the lunch rush.

The toilet bowl must connect to the drainage pipe under the floor so gas and water don’t leak into your home. For many decades this was done using a wax gasket. For the gasket to produce a seal there needs to be about a 3/8-inch gap between the top of the toilet flange and the underside of the toilet china. The flange is a special fitting that is attached to the top of the drain pipe. The toilet bolts to this flange.

Too small of a gap between the toilet and the flange can squeeze too much wax out and too much of a gap means the wax doesn’t make a perfect seal between the toilet and the flange. Wax gaskets, in my opinion, are the best seal you can get. Newer gaskets made of rubber can fail over time if they dry out. Wax composition never changes.

Your toilet flushes away waste using simple physics. Remember that easy formula in high school? Force equals mass times acceleration. The force of the flush is created by the mass of water that accelerates as it travels from the tank down into the bowl. Gravity helps do this in your home. In most commercial toilets, this force is created by the water pressure in the water supply line. My guess is you’ve never really thought much about the absence of a toilet tank in most commercial restrooms.

Older toilets did a better job of flushing and carrying the waste to the city sewer or septic tank because they had more mass. Old toilets typically had twice the amount of water flow into the bowl than modern toilets. Very old toilets had the tanks up about six feet in the air. Those really flushed well because the water had more hydrostatic head.

The two moving parts inside your toilet tank are the things that flummox most homeowners. You just have a fill valve and a flapper valve. The fill valve allows fresh water to fill the tank after you flush. The flapper valve stops the tank water from flowing into the bowl after the tank fills with new water.

You can adjust the fill valve so that you get the maximum amount of water flowing into the toilet bowl with each flush. To do this, you adjust the float on the fill valve to stop the flow of water just as the level in the tank rises to the top of the overflow tube. This tube is a drain pipe that prevents water from overflowing the toilet tank should the fill valve malfunction and not shut off. Can you imagine the flood in your home if you walked out of the bathroom and water started to overflow the tank? Oh my!

Worn-out flapper valves create phantom flushers. Have you ever heard your toilet tank start to briefly refill when no one has used the toilet? You might think a ghost flushed the toilet! The cause is simple. A small amount of water seeping past the flapper valve causes the level of the water to drop in the tank over a period of a few minutes. As the fill valve float drops, it eventually triggers fresh water to enter the tank.

You can test for these small leaks by using food coloring. Clean your toilet bowl well and then flush the toilet. Once the fill valve stops the water from entering the tank, wait about 30 seconds. Squirt a generous amount of green food coloring into the tank water. Come back into the bathroom an hour later to see if the color of the water in the bowl is a light shade of green. If so, it’s time to replace the flapper valve.

The internet is overflowing with helpful videos showing you how to install new fill valves and flapper valves. It’s extremely easy and so long as you can turn off the shut-off valve that supplies water to your toilet tank, you can do these repairs with minimum tools.

Column 1476

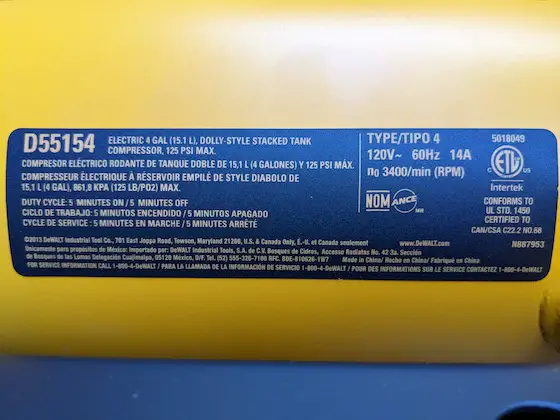

This is the business end of the DeWALT D55154 Air Compressor. It's caveman simple to operate. Check the oil level in the back, plug it in and get to work!

I've had quite a few portable air compressors in my time. My first one was a wretched sound machine gasoline-powered one. It was heavy and its engine drove you crazy after a few hours.

Ever since then I've always had an electric compressor as even on job sites, you almost always have power available without having to use a generator.

This DeWALT D55154 Air Compressor can easily power two large pneumatic air tools and not strain. I loved how compact it was and it's really not that heavy. I could lift it up into my truck with very little strain.

These are the two gauges. The one monitors the pressure in the tanks. The other one tells you how much pressure is going out to your tools.

You can connect two air hoses to the compressor. You just push the end of the hose into the brass fitting to make an air-tight connection.

You can see the sturdy pipe frame.

This is the cylinder that compresses the air. The aluminum casing contains the lubricating oil. Always check the oil level before operating. The dipstick that was shipped attached to the power cord goes into the top where you see the flat red cap that is holding in the oil that was put in at the factory. Note that it tells you the oil type to use and how much to add once you drain the oil out. It's wise to change the oil once it appears the slightest bit dirty. READ the manual about the time of the first oil change!!!

This handy handle comes with the compressor. It's well balanced and you'll feel like you could wheel this through an airport concourse with ease.

This is the all-important drain plug. You MUST drain the water from the tanks after each use to prevent internal rust.

This is where the power cord stows.

Here's the specs. You'll not regret putting in a 20-amp circuit in your garage as this draws 14 amps!

I don't think you need to keep a spare tire around. But you can see the tire size. They inflate with ease.

Subscribe to the FREE Ask the Builder newsletter to receive professional advice for your home. Complete the form below and each week you'll get:

Unsubscribe at any time. We respect your email privacy.