Concrete bags on a pallet are ready for water and a hoe. You can transform these bags of concrete into many things around your home. You just need minor skills and practice! Photo Credit: Tim Carter

"Believe it or not, the concrete in the bags that you see at hardware stores and home centers is pretty much the same concrete you would get if you called a ready-mix plant...."

Concrete Bags Make Superb Concrete

- perfect for small projects

- mixes easily in a wheelbarrow or plastic sheet

- mix until it's like firm applesauce

- too much water weakens concrete in a bag

DEAR TIM: I need to replace a small section of sidewalk that's only 4 feet by 4 feet. I've never worked with concrete before and wonder if I can actually do this.

I see the bags of concrete at the hardware store and could easily get these to my home. What's involved with this process and how can I succeed the first time?

What tools would I need to purchase? What are some tips you can share to help me do this job? I have other concrete projects but am anxious about whether I can do them. Julie Q., Campton, NH

Mix Concrete in a Tough Plastic Bag

DEAR JULIE: I love your attitude. Many people get frozen in their fear of failure and don't even try to do a job like this. I can already tell you that you will do well, especially if you follow my tips.

Is Concrete in a Bag Strong?

Concrete in a bag is strong as long as you use the correct amount of water when mixing it. Some come with a 4,000 pounds per square inch (PSI) rating. It's important to realize you can add more Portland cement to make it even stronger.

Let's talk about the actual concrete mix in the bags. Believe it or not, the concrete in the bags that you see at hardware stores and home centers is pretty much the same concrete you would get if you called a ready-mix plant and had it delivered to your home in a giant truck equipped with a rotating drum.

Is Ready-Mix Concrete in Trucks Better?

The ready-mix concrete plant can make all sorts of different mixes for you. They offer convenience as they mix the material.

There are some disadvantages from using ready-mix concrete:

- large trucks weighing over 70,000 pounds may crack your driveway

- small loads can be very expensive.

- you often need many people to help unload

What Strength Concrete Do I Need?

You need a minimum of 4,000 PSI concrete for concrete exposed to freezing weather. Remember, that's the minimum strength. It's better to pour it 4,500 or 5,000 PSI.

Concrete is formulated at different strengths. Most of the bagged concrete mixes are rated at 4,000 pounds per square inch (psi). That strength is achieved so long as you don't add too much water to the mix. They tell you on the bag labels how much water to add to get to that strength. Pay attention to that.

Will Concrete Last in Cold Climates?

4,500 PSI strength is very good for concrete exposed to freeze-thaw cycles in cold climates. Concrete absorbs liquid water, and this water inside concrete can tear it apart if the bonds between the cement, sand, and gravel are not strong.

You weaken concrete by adding too much water to it when you mix it or if you add water to it as you finish it.

Is it Easy to Mix Concrete in a Bag?

It's pretty easy to mix concrete. I do it in a wheelbarrow.

I've seen a unique bag system where you just put the dry concrete mix in a strong plastic bag, add the water and move the bag back and forth.

Both methods work well. You can even mix concrete using heavy sheets of plastic in case you can't purchase the plastic mixing bags.

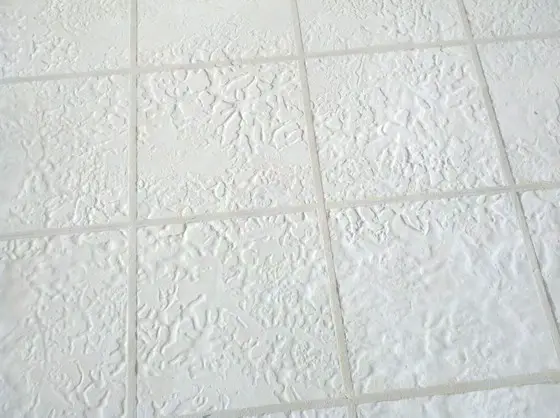

Is it Easy to Finish Concrete in a Bag?

It is easy to finish concrete. You just need to follow a few steps:

- screed the concrete so there's no excess between the form boards

- float the concrete to drive the rocks down from the surface

- the top 1/4 inch of the surface of the concrete should just be the coarse sand and Portland cement

- wait for it to stiffen up, rub with a magnesium or wood float

For you to succeed on your sidewalk, I need you to first practice finishing concrete. Mixing is easy, but finishing requires some skill. I highly recommend that you pour a small, thin test slab first to practice to see how concrete transforms from the plastic to the hard state.

Should I Do a Practice Pour?

Buy one bag of the concrete mix. Look on the label for a table that shows you how far it will go. You should be able to make a small thin slab about 2 feet by 2 feet that's only 2 inches thick. That's plenty big to practice.

Lay a sheet of 6 mil plastic on your garage floor. Build a small square form from wood that will hold the concrete. Lay this form on the plastic. Mix the bag of concrete mix with the required water and mix until it's a uniform texture. Remember, you can always add more water. Add the water in stages as you mix.

Pour the mixture into the form. Use a straight piece of wood to make the concrete flush with the top of the wood forms. Slide the piece of wood side to side rapidly as you pull or push the piece of wood from one end of the form to the other. This double action eliminates voids on top of the slab and helps drive the stones down below the surface.

When Do You Float the Fresh Concrete?

You want the top of the concrete to be the coarse sand and cement paste with the stones in the mix perhaps down about 1/8 or 1/4 inch. This sandy top layer allows you to create the desired finish.

You'll need a wood or magnesium hand float tool and an edging tool to produce the smooth edges for your slab. If your existing sidewalk finish is a broom finish with just lines, you'll just need a push broom to create the final texture.

You have to wait about 30 minutes or an hour before you can start to put a finish on fresh concrete. It depends on the temperature of the concrete, the air temperature and the relative humidity of the air.

When freshly mixed, you can easily put your finger deep into the mix. You do not want to start to finish the concrete until it has started to firm up. When the concrete is hard enough that thumb pressure indents it about one-half inch, start to rotate the hand float on the surface and see what happens. It should produce a great result!

You can watch several videos that show how to mix and place concrete at www.AsktheBuilder.com. Simply type "concrete video" into the search engine. There are MANY ADDITIONAL Concrete Finishing tips here at www.AsktheBuilder.com.

Column 944