What’s in This Issue?

PEX Tubing vs. Copper Tubing

Rusty Gas Piping

News About Stain Solver

Window Leak

Pocket Door Update

Time is Running Out

Latest Columns and Video

FOLLOW ME ON TWITTER

Friendly Question Reminder!

If you have a question for me, don't hit the Reply button just yet. Go immediately to my web site and type in the keywords about your problem into my Search engine. The search box is at the top of every page of my web site. You could have your answer in seconds if you do this! Please pay attention to all links you see at my web site. The exact products and services you often need are right in front of you, and you might be ignoring them.

I'm in New Hampshire writing this today, but tomorrow I'll be driving towards Cincinnati, OH to do some exterior work on our house there to get it ready to sell. I'll also be monitoring the roofers who will be putting on the new GAF Slateline shingles. Wait until you see the eBooks and videos that I'll be producing about different aspects of the roofing job. Wow!!!

I'll also be shooting a video or two in the newly remodeled master bathroom. I have some cool things to show you in that room. If you live in or around Cincinnati and want to get together one evening at a local establishment, send me an email with "Cincy Visit" in the subject line. I'll then email you with a time and place where we can all have a drink and visit with one another.

If you work for a company that makes or promotes home-improvement products, remember that I actively test as many tools and products as possible sharing the results here in the newsletter.

PEX Tubing vs. Copper Tubing

Jenee Bobbora, a subscriber to this newsletter asked me an interesting question overnight:

"Do you have an opinion on PEX vs. Copper plumbing? I have to decide ASAP, and my builder tells me that right now they are priced about the same. The PEX carries some extra cost due to the special tools that are needed.

I live in Houston, TX, and it is hot here. I am a bit concerned about my water sitting in plastic pipes but most people I ask say it is better than copper now for a number of reasons. I would love to know your thoughts."

Jenee, I'm a licensed master plumber, and have been one for many years. Installing copper is what I did for over 30 years. It takes lots of time to cut copper tubing, clean the ends, clean the fittings and solder all of that. None of that effort is required for PEX tubing. You run one continuous piece of tubing from a central manifold to the fixture. It takes seconds to crimp on a brass fitting to the PEX tubing.

The PEX should not cost more because of the crimping tool, it should cost less! There's an enormous time savings in labor. What's more, the tools are used on job after job, so the cost of the crimping tool is amortized over many jobs. Add up the cost of an acetylene torch, the B-tank, tubing cutters, etc. and I'll bet a plumber can spend as much for copper tools as he might for the cutter and crimper for PEX.

I have PEX tubing in my New Hampshire home. It's used for both my water lines and my radiant heating system. I love it. Even though I used copper for years in all the jobs I did as a plumber and builder over the years, I'll be using PEX in the new home Kathy and I will build soon. Copper is a wonderful time-tested material, but there have been issues with it and aggressive water. There were also issues with early PEX systems, but I feel those have been solved and that the connections between the PEX and the fittings are now reliable.

Read this about aggressive water.

Rusty Gas Piping

Last year here in New Hampshire, I had a standby generator installed. Next week, I should have a video loaded for you to watch about it. Part of the install included running a new propane gas line to the generator. It was cold at the time and impossible to paint the black iron piping that was used in two locations where the gas-pipe risers come up out of the ground.

The pipes developed a thin coating of rust in the past nine months. It's important to paint exposed black iron pipe because if left alone, the rust will eventually cause a gas leak. All you have to do is look at the exposed threads on some of the pipe. You can clearly see that metal has been cut away at the threads making the pipe thinner at the threads. The rust weakens the piping and if subjected to stress, the pipe can snap at a thin thread where it connects to a fitting.

I used a special Rustoleum primer that's formulated to bond to metal that has lightly rusted. The printing on the small can is so tiny I can't read to see if the paint contains zinc chromate. If it does, that's a very good thing as this material bonds well to rusty metal and prevents rust once you apply the finish coat of paint. I'll be applying the finish paint just before lunch today as soon as it warms up. Be sure you paint any rusty gas piping inside or outside your home.

News About Stain Solver!

If you're a new subscriber, you may not know about Stain Solver. It's a fantastic oxygen-bleach cleaner Kathy and I developed about 13 years ago. In the past year, I decided to really pay attention to the business and make it grow.

I got an email yesterday telling me that the Stain Solver business was nominated for a special grant to help market the business. If I was lucky enough to win, the grant could help me do things that I've always wanted to do.

But I need your help now, meaning right now. To proceed to the judging phase, I have to get as many endorsements as possible. Some companies in this competition have over 1,000. Would you consider voting for me? You have to do a simple registration at this website to vote, but it takes less than a minute or so.

Please go here and read the story. In the left column, you'll see a blue button that says: Endorse this Story Now. But up at the top you'll see a small text link that says Login or Register. You have to register in order to endorse me. Thanks so much for doing this for me, and wish me good luck!

Window Leak

A friend of mine just discovered a chronic leak beneath a window at his home. The cause of the leak was traced to Tyvek that had been improperly installed. On top of that the window was not flashed properly.

If you're doing a room addition or building a new home, it's mandatory that you invest the time at the website of the window and door manufacturer whose products will be used on your job. Take the time to review the printed installation instructions or any videos they may have posted. You then need to make sure your windows are installed correctly. This means you must inspect the work or pay a professional to do it for you. It's not easy, I know that. But unfortunately you must take some responsibility to ensure the job gets done right.

Pocket Door Update

Recently, I've been telling you about a pocket door I installed in Kathy's new bathroom. These doors are space savers and they can be trouble-free if you use the right hardware and frame. One thing I discovered years ago is the advantage of pre-painting the door before it's installed. As with all doors, it's very important that you paint all surfaces, especially the top and bottom of the door. You can't allow pocket doors to warp. Not painting the top and bottom of the door increases the likelihood of warping as water vapor can enter the end grain of the two vertical stiles of the door.

Time is Running Out

With winter just around the corner, remember that certain projects are temperature sensitive. Read the labels on paint, sealers, etc. and they have a minimum application temperature. Some products also need to cure several hours before the temperature can drop to a certain level. Failure to do this can lead to problems.

Get these projects done now before you bump up against these temperature restrictions. Okay, I don't want to hear from you if you're a gloater who lives in southern Florida or sunny southern California where the temps are nearly always above the limits year round. Blah blah blah...... :-> But if you do email me and get in my grill about your great weather, we'll talk about hurricanes and firestorms instead.

Latest Columns and Video

I took a cool hike to the top of Foss Mountain in New Hampshire on Labor Day.

Do you really need a Firewood Rack?

What kind of pegboard should you install?

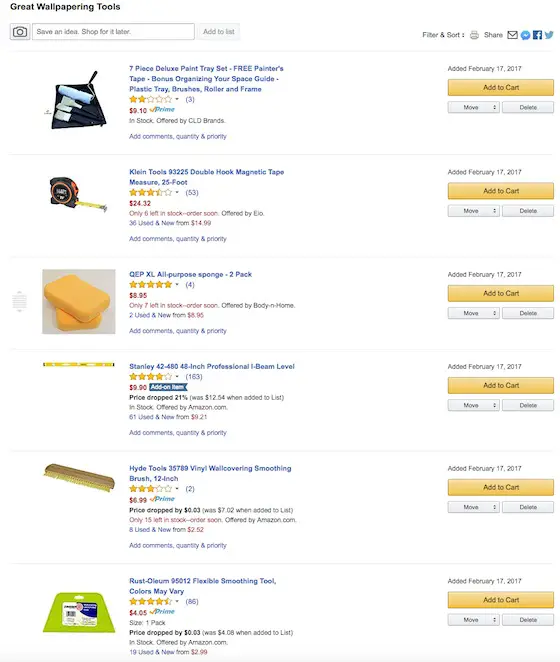

Do wallpaper and tie dye clothing clash? Look at the photo in this column. Ignore bald spot.

There are different ways to paint a door. Here's one way I do it to get pro results.

AsktheBuilder.com