Penetrating Masonry Stains & Sealers

People like colors. Colors allow tremendous decorating possibilities. They freshen and brighten things. Not too long ago, the only way to apply color and weather protection to the outside surfaces of a house was by using paint.

Modern technology has offered us alternatives. Penetrating stains and sealers are available which allow us to protect exterior surfaces without some of the disadvantages of paint.

Paints, for the most part, are coatings. After they are applied, most paints adhere to the outside surface of the object they are coating. Rarely do they penetrate into the surface of the object being painted.

In some cases, this attribute is a positive quality. For example, paint allows you to achieve a surface texture somewhat different than the substrate. Paint can make things smoother, especially when applied in successive layers.

CLICK HERE to get FREE & FAST BIDS from local painters who can paint or stain your exterior walls.

However, because paint (in almost all instances) is a coating, it is highly susceptible to peeling and blistering. Virtually every homeowner has dealt with this problem. Often, people mistakenly blame the paint or coating, when in fact it has nothing to do with the product.

Peeling and blistering often develop as a result of vapor pressure which passes through the object (wood siding, plaster,concrete, stucco, etc.) and subsequently pushes the paint out of the way. Simply put, vapor pressure can exceed the bonding strength of paints.

For this reason, research and development teams at coatings (paint) companies tried another angle.They decided to develop products which would allow you to achieve all protection and decorating goals, but avoid the peeling and blistering problems.

They did this by developing penetrating stains and sealers. Many of these products can be tinted to any color. Some of them are clear. They can achieve spectacular results when properly applied.

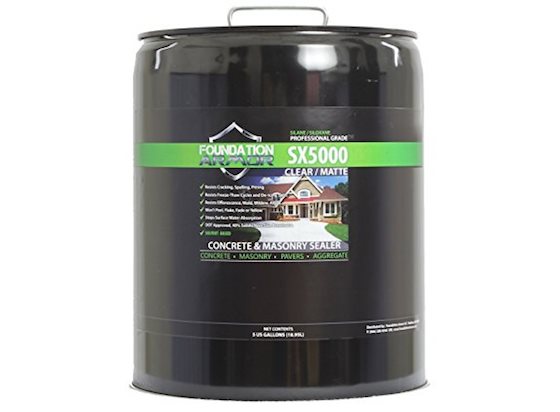

This is a magnificent silane - siloxane water repellent that soaks into concrete. CLICK THIS IMAGE NOW TO ORDER IT.

Exterior masonry surfaces are perfect substrates (surfaces) for these products. Although masonry surfaces look 'solid', they are in fact far from it. Masonry surfaces, when viewed under a microscope, look somewhat like a sponge.

There are void spaces for water and small particles to enter. The penetrating stains and sealers take advantage of these void spaces. Many of these products contain solids (resins, pigments, etc.) which are carried into the void spaces by the liquid portion (vehicle) of the stains or sealers.

When the liquid portion evaporates, the solid particles are left behind to produce color, provide protection, or both! It really is very simple when you think about it.

Several manufacturers of these products have gone the extra mile. They have formulated their products so that they do not totally block the void spaces. This is extremely important.

If you purchase a product which does, in fact, block all of the void spaces you can get into trouble. Remember what I said several paragraphs ago, about vapor pressure and products that block the movement of water vapor?

In certain climates, you need water vapor to freely pass through masonry, cement, or wood. For example, in colder climates the humidity levels inside of heated houses is almost always higher than the colder outside air humidity levels.

These levels strive for equilibrium. That is, the high humidity is attracted to the areas of lower humidity. If you use a stain or sealer which blocks water vapor movement you can have a problem.

The water vapor can collect next to the stain or sealer, condense into a liquid, freeze, and subsequently damage the surface of the object you are trying to protect! For this reason, you must determine that the product you use does not restrict the movement of water vapor.

On the other hand, there may be instances when you wish to block water vapor movement. For example, let's say that your basement walls, floor or regular floor slab was not damp-proofed or treated in some manner to block water vapor transmission.

Water or dampness in the soil will constantly try to get to a drier area (the air on the other side of the wall or slab). There are sealers made which will completely block water vapor movement in these cases.

Just make sure you use the right product for the right job. Also, in the event that you decide to use a product indoors, BEWARE of products that contain hydrocarbons or other explosive vehicles!!!!

These products produce fumes which can readily explode. The pilot light from furnaces or water heaters can easily ignite them. Be sure to read product labels!!!!

Tips on Stucco Maintenance

Stucco, because it is a cement-based material, can be extremely durable. When properly mixed and installed, it can be virtually maintenance free. However, some people do not particularly like the color of stucco in its natural state.

Also, in some climates, it is advantageous to protect stucco. For example, in hot, dry climates, stucco may experience excessive efflorescence caused by rain water or sprinkler water which saturates unprotected stucco.

Stucco, in wet climates, can absorb water and cause interior damage. You need to study the climate factors in your area and plan accordingly. There are publications which can help you.

The Portland Cement Association (PCA) has several fine publications which deal with stucco. Two of them immediately come to mind. The Concrete Masonry Handbook and The Homeowner's Guide to Building with Concrete, Brick, & Stone have very good descriptions covering stucco or Portland cement plaster, as it is commonly referred to.

Also, be sure to check out the PCA's online Bookstore. While much of their literature is written for the professional, much of it is very clear and understandable for the average homeowner. Many of their books and pamphlets may interest you.

Manufacturers of Masonry Stains & Sealants

Following is a partial list of companies which manufacture certain masonry stains and sealants. Many of them make environmentally friendly water based products. Also, be sure to read the specific installation guidelines.

When applied to new masonry surfaces, often it is very important as to how soon a product can be applied to the fresh (non-dry) masonry. Be sure to ask and get it in writing to avoid misunderstandings!!

- Decosup

- Fabcrete

- Benjamin Moore Paints

- Rainguard Color-Lok

- Waterlox Chemical & Coating Corp.

- Tamms - Euclid Chemical Company

- Weather-Bos International

CLICK HERE to get FREE & FAST BIDS from local painters who can paint or stain your exterior walls.

Column B43